My Garage

My Account

Cart

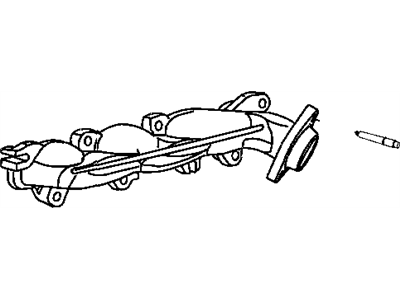

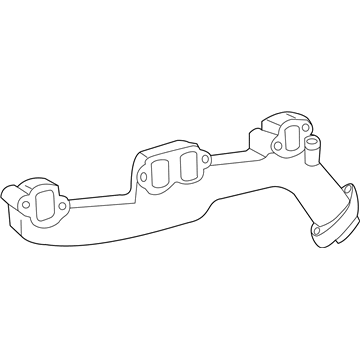

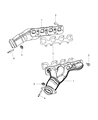

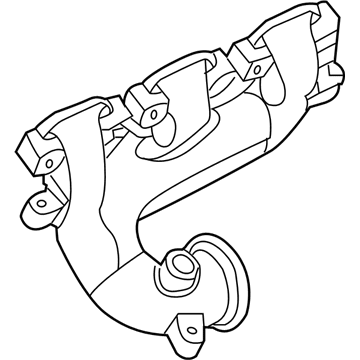

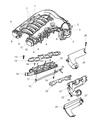

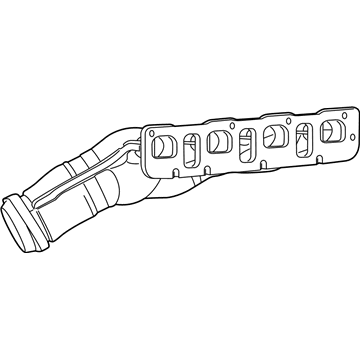

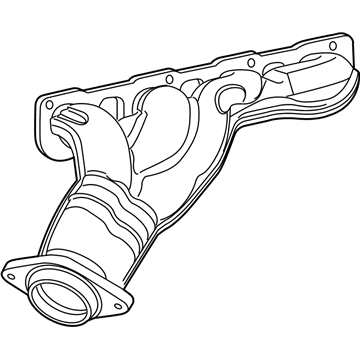

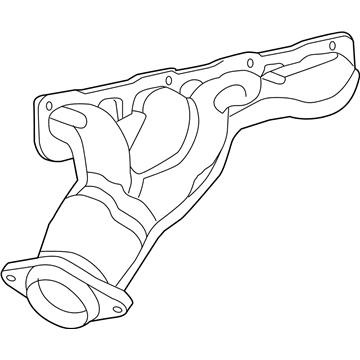

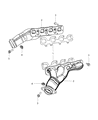

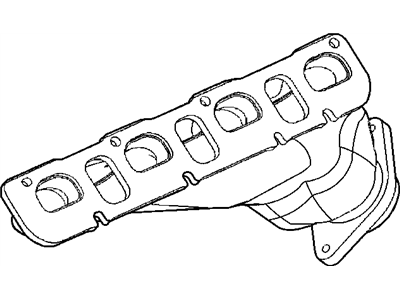

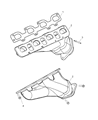

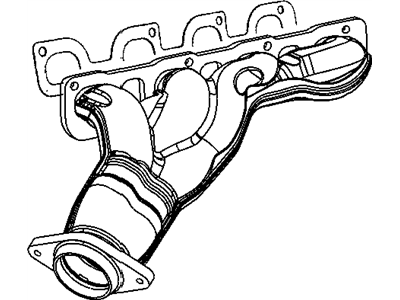

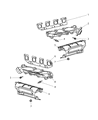

Genuine Chrysler 300 Exhaust Manifold

Engine Exhaust Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Exhaust Manifolds found

| Page 1 of 2 |Next >

1-20 of 21 Results

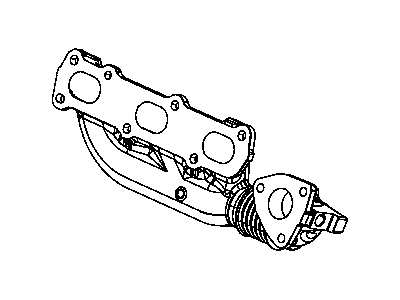

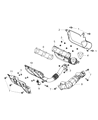

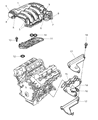

Chrysler 300 Exhaust Manifold

Exhaust Manifold of Chrysler 300 is particularly vital in channeling hot flames from the automobiles' engine to the exhaust mechanism in order to enhance its performance and minimize emission of dangerous gases. Located anywhere between the sides of the engine block, the manifold is created to avoid intake reversion which disrupts air flow and ultimately decrease the performance of an engine. Exhaust manifold types used in Chrysler 300 models varies and usually are cast iron or stainless steel parts. There are modifications which are called headers that improve the performance by minimizing the flow restriction and maximizing the velocity of the exhaust gases. These differences can be clearly observed in the material and design of the exhaust manifolds which in turn do manifest on the performances of the vehicle in terms of the power that it can deliver as well as the efficiency it can harness from the same power. This is why periodic checks and timely repair or replacement of a damaged exhaust manifold plays a critical role in keeping the car's performance optimum and the occupants of the car from any adverse health effects from exhaust gasses.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler 300 Exhaust Manifold at great affordable prices. Moreover, all genuine Chrysler 300 Exhaust Manifold come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler 300 Exhaust Manifold Parts Questions & Experts Answers

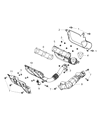

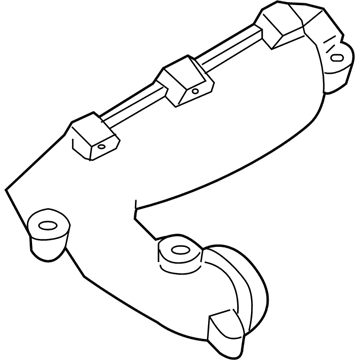

- Q: How to remove and install an exhaust manifold in 2.7L V6 engine on Chrysler 300?A:Disconnect the cable from the negative terminal of the battery. Block the rear wheels, set the parking brake, raise the front of the vehicle and support it securely on jackstands. Disconnect the downstream oxygen sensor connectors. Remove the engine middle splash shield. Unbolt the exhaust pipes at the exhaust manifolds. Lower the vehicle. Working in the engine compartment, disconnect the oxygen sensor's electrical connector. If removing the right exhaust manifold, detach the EGR pipe from the top of the manifold. If removing the left manifold, remove the air filter housing and the engine oil dipstick tube. Remove the exhaust manifold upper heat shield mounting bolts and remove the heat shields. Remove the mounting bolts and detach the manifold from the Cylinder Head. Be sure to spray penetrating lubricant onto the bolts and threads before attempting to remove them. Clean the mating surfaces to remove all traces of old gasket material, then inspect the manifold for distortion and cracks. Warpage can be checked with a precision straightedge held against the mating flange. If a feeler gauge thicker than 0.030-inch can be inserted between the straightedge and flange surface, take the manifold to an automotive machine shop for resurfacing. Place the exhaust manifold in position with a new gasket and the lower heat shields and install the mounting bolts finger tight. Starting in the middle and working out toward the ends, tighten the mounting bolts in several increments, to the torque. Install the remaining components in the reverse order of removal. Start the engine and check for exhaust leaks between the manifold and cylinder head and between the manifold and exhaust pipe.

Related Chrysler 300 Parts

Browse by Year

2023 Exhaust Manifold 2022 Exhaust Manifold 2021 Exhaust Manifold 2020 Exhaust Manifold 2019 Exhaust Manifold 2018 Exhaust Manifold 2017 Exhaust Manifold 2016 Exhaust Manifold 2015 Exhaust Manifold 2014 Exhaust Manifold 2013 Exhaust Manifold 2012 Exhaust Manifold 2011 Exhaust Manifold 2010 Exhaust Manifold 2009 Exhaust Manifold 2008 Exhaust Manifold 2007 Exhaust Manifold 2006 Exhaust Manifold 2005 Exhaust Manifold