My Garage

My Account

Cart

Genuine Chrysler Cirrus Camshaft Seal

Cam Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Camshaft Seals found

Chrysler Cirrus Camshaft Seal

In Chrysler Cirrus vehicles, the Camshaft Seal plays an important function in the safety of the engine, as it shields it against dirt particles and oil and all elements that could make their way into the part of the camshaft that is positioned outside the cylinder head. This seal is critical to ensure adequate lubrisation of the camshaft as the later is crucial to the efficiency of the engine. Camshaft Seals fitted in Chrysler Cirrus models are chosen to filter out unwanted materials in order to perform to the optimum. While the overview does not specify different types or styles of Camshaft Seals used across various Cirrus vehicles, the primary function remains consistent: preserving the state and increasing the durability of the engine. The Camshaft Seal plays an important part in the reliability of the Chrysler Cirrus, a fact reflected in the assessment of where and how that component functions.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Camshaft Seal at great affordable prices. Moreover, all genuine Chrysler Cirrus Camshaft Seal come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Camshaft Seal Parts Questions & Experts Answers

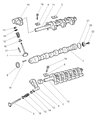

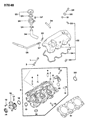

- Q: How to replace Camshaft Seal in V6 engine on Chrysler Cirrus?A:Do not rotate the Camshafts or crankshaft when the timing belt is removed or damage to the engine may occur. Begin by removing the timing belt. Rotate the crankshaft counterclockwise until the crankshaft sprocket is three notches BTDC to prevent engine damage if the camshaft sprocket is inadvertently rotated during removal. While keeping the camshaft from rotating, remove the camshaft sprocket bolt, then use two large screwdrivers to lever the sprocket off the camshaft. A strap-type damper/pulley holder tool is recommended for this procedure, but if the old timing belt is not being reused, wrapping a piece of it around the sprocket and using a chain wrench can also hold the sprocket in place. Carefully pry out the camshaft oil seal using a small hooked tool or screwdriver, taking care not to scratch the bore or damage the camshaft, as damage will cause the new seal to leak. Clean the bore and coat the outer edge of the new seal with engine oil or multi-purpose grease, also lubricating the seal lip. Using a socket with an outside diameter slightly smaller than the seal and a hammer, carefully drive the new seal into the cylinder head until it's flush with the face. If a socket isn't available, a short section of pipe can be used. If engine location makes it difficult to use a hammer, fabricate a seal installation tool from a piece of pipe cut to the appropriate length, a bolt, and a large washer, placing the pipe over the seal and threading the bolt into the camshaft to press the seal into the bore by tightening the bolt. Install the camshaft sprocket, aligning the pin in the camshaft with the hole in the sprocket, and using an appropriate tool to hold the camshaft sprocket, tighten the camshaft sprocket bolt to the specified torque. Finally, install the timing belt and run the engine to check for oil leaks.