My Garage

My Account

Cart

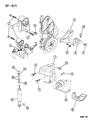

Genuine Chrysler Cirrus Engine Mount

Engine Motor Mount- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

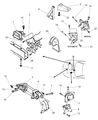

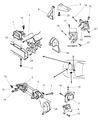

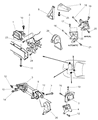

11 Engine Mounts found

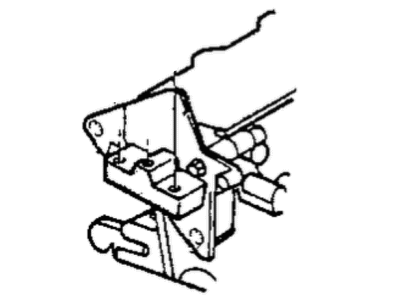

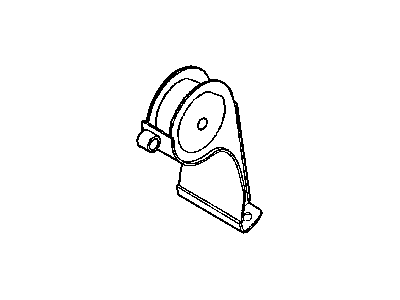

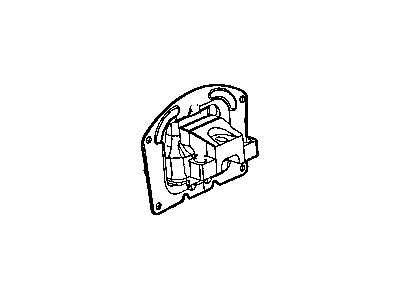

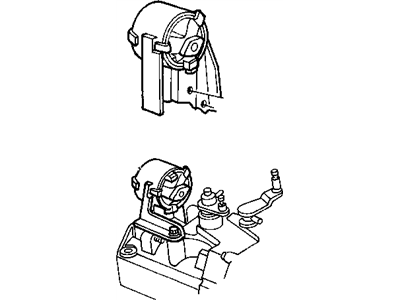

Chrysler Cirrus Engine Mount Bracket

Part Number: 4593455AA$62.30 MSRP: $103.00You Save: $40.70 (40%)

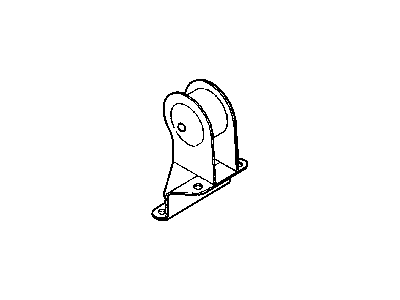

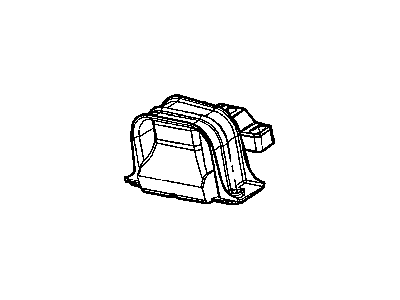

Chrysler Cirrus Engine Mount

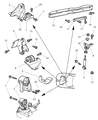

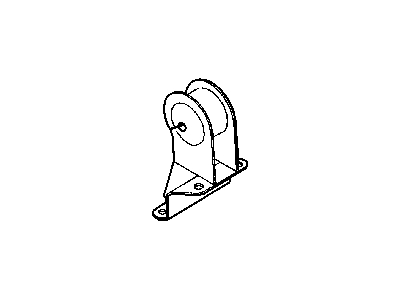

The Engine Mount in Chrysler Cirrus vehicles serves two primary functions: It isolates sound and vibration arising from operation of the engine while at the same time, it gives proper support and location of the engine and transaxle within the combination of chassis. This isolation is specifically imperative for the purpose of comfort but it can also be very important to ensure that the correct position of the engine is preserved so as to avoid certain hazards especially to the parts of the vehicles. Chrysler Cirrus vehicles have had various types of Engine Mounts throughout their years of production, they have had rubber Engine Mounts, the fluid filled hydraulic Engine Mounts and the electronic active Engine Mounts. While traditional mounts are made of metal components with rubber subassemblies in-between, hydraulic mounts are able to absorb more vibrations. Active mounts that are most advanced are capable of changing stiffness depending with the revolutions per minute of the engine. They are often referred to as Engine Mounts and can wear out due to age, heat or exposure to fluids and may exhibit signs which include unusual noises and vibrations hence requires either inspection or replacement.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Engine Mount at great affordable prices. Moreover, all genuine Chrysler Cirrus Engine Mount come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Engine Mount Parts Questions & Experts Answers

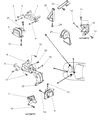

- Q: Do engine mounts require attention, and what steps should be taken if they are broken or deteriorated in V6 engine on Chrysler Cirrus?A:Engine mounts seldom require attention, but broken or deteriorated mounts should be replaced immediately to prevent damage or wear on driveline components. During the check, the engine must be raised slightly to relieve the weight from the mounts. Raise the vehicle and support it securely on jackstands, then position a jack under the engine oil pan with a large wood block between the jack head and the oil pan to prevent damage, and carefully raise the engine just enough to take the weight off the mounts. Inspect the mounts for cracked, hardened rubber or separation from the metal backing, as the rubber may split down the center. Check for relative movement between the mount plates and the engine or frame using a large screwdriver or pry bar; if movement is noted, lower the engine and tighten the mount fasteners. Applying rubber preservative may help slow deterioration. To replace a mount, disconnect the negative battery cable from the ground stud on the left shock tower, raise the vehicle, and support it securely on jackstands. Place a floor jack under the engine with a wood block between the jack head and oil pan, then raise the engine slightly to relieve the weight from the mount to be replaced. For 1995 through 1997 models, the lower front engine mount is attached to the lower radiator support, so the radiator and air conditioning condenser must be supported when removing the engine support module. Remove the fasteners and detach the mount from the frame and engine, taking care not to disconnect more than one mount at a time, except during engine/transaxle removal. Installation is the reverse of removal; use thread locking compound on the mount bolts and ensure they are tightened securely.