My Garage

My Account

Cart

Genuine Chrysler Cirrus Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Flywheel found

Chrysler Cirrus Flywheel

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Flywheel at great affordable prices. Moreover, all genuine Chrysler Cirrus Flywheel come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Flywheel Parts Questions & Experts Answers

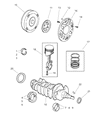

- Q: How do you remove and reinstall the driveplate in four cylinder engine on Chrysler Cirrus?A:When removing the transaxle assembly, first, lift the car with the help of a jack and put the jackstands in the proper position. In vehicles that have a manual transaxle, it is desirable to check or replace the modular clutch assembly at this time. Due to wear and tear, components of the assembly may require replacement hence the need to match mark the drive plate and the backing plate to the crankshaft to guide reassembly. Second, take off the nuts that fasten the flywheel or the driveplate to the crankshaft; a useful tool in this case is a spacer, that can be bought in most auto part stores, or one can jam the driveplate with a screwdriver between the starter ring gear teeth. When it's separated from the car, clean the driveplate thoroughly-the grease and oil will have to be wiped out, and after that, check for any cracks and distortion as well as ring gear teeth, which may be missing or worn out; in that case, the driveplate will have to be replaced. Also, clean and inspect the mating surfaces of driveplate and crankshaft, if the crankshaft rear main seal is bad replace it before putting in the driveplate. To install the driveplate, place it and the backing plate on crankshaft, making sure of the match marks which have already been applied. Before tightening the bolts, there is need to apply the thread locking compound on the respective threads. Temporarily use the special holding tool which fits into the driveplate or put the blade of the screwdriver in between the starter ring gear teeth and then tightening the bolts to the recommended torque. The other processes are done in the reverse manner to uninstallation processes outlined above.