My Garage

My Account

Cart

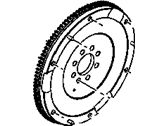

Genuine Chrysler PT Cruiser Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Flywheels found

Chrysler PT Cruiser Flywheel

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler PT Cruiser Flywheel at great affordable prices. Moreover, all genuine Chrysler PT Cruiser Flywheel come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

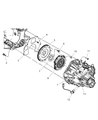

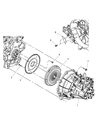

Chrysler PT Cruiser Flywheel Parts Questions & Experts Answers

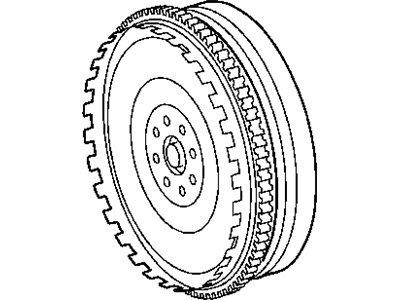

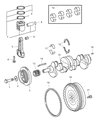

- Q: How do you remove and reinstall the Flywheel on Chrysler PT Cruiser?A:To remove the transaxle assembly, first raise the vehicle and support it securely on jackstands. If equipped with a manual transaxle, take out the pressure plate and clutch disc, using this opportunity to check or replace the clutch components and pilot bearing. Before removing the flywheel/driveplate, mark its position relative to the crankshaft to ensure correct alignment during reinstallation. Next, remove the bolts securing the flywheel/driveplate to the crankshaft; a tool to hold it in place can be found at most auto parts stores, or a screwdriver can be wedged in the ring gear teeth to prevent movement. Carefully take off the flywheel/driveplate, supporting it while removing the last bolt, and clean it to eliminate grease and oil. Inspect the mating surfaces of the flywheel/driveplate and crankshaft, replacing the crankshaft rear main seal if it is leaking before reinstalling. For installation, position the flywheel/driveplate against the crankshaft, aligning the match marks, and apply thread locking compound to the bolt threads before tightening them while holding the flywheel/driveplate in place. The rest of the installation follows the reverse order of removal.