My Garage

My Account

Cart

Genuine Chrysler PT Cruiser Release Bearing

Clutch Release Throw Out Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Release Bearing found

Chrysler PT Cruiser Bearing-Clutch Release

Part Number: 4670026AB$97.79 MSRP: $129.00You Save: $31.21 (25%)

Chrysler PT Cruiser Release Bearing

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler PT Cruiser Release Bearing at great affordable prices. Moreover, all genuine Chrysler PT Cruiser Release Bearing come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler PT Cruiser Release Bearing Parts Questions & Experts Answers

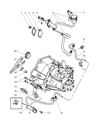

- Q: How do you remove and install the Clutch Fork and Release Bearing on Chrysler PT Cruiser?A:Do not allow brake fluid to splash on painted surfaces since it will remove the paint. For non-turbocharged models, for the reason of the high degree of difficulty in removing the transaxle for release bearing replacement, it is advised to replace the release bearing together with the clutch components periodically. First, it is required to remove the cable from the negative terminal of the battery. Remove the transaxle. It should not be unbent with a screwdriver or prybar as the spring clip will be technically harmed. Swing the fork or the bearing into the position that will have the fork perpendicular to the input shaft and lock it with a screwdriver or needle nose pliers, the head of the spring clip. The release bearing can be held in place and the clutch fork pulled out for removal from the pivot stud and the release bearing is removed from the input channel. In the case of turbocharged models, a hydraulic quick-connect fitting is to be removed from the release cylinder, and the transaxle is to be pulled out. Unbolt the transaxle and free the release cylinder from the shaft and then slide the entire release cylinder assembly backward and out of the way. In inspecting, grasp the bearing at the outer race, and then try to rotate the inner race along with some pressing force; if it does not rotate smoothly or rotates with noises, then replace the bearing assembly with a new one. Coil a cloth and wipe the bearing, check for damage-wear-cracks do not immerse in solvent because the bearing is sealed for life. It is also important to check the clutch fork for any cracks or bends and clutch fork wear or damage particularly where they come into contact with the release bearing. Any dirt that shows on the pivot ball stud and stud pocket in the clutch fork needs to be cleaned out first. For non-turbocharged models, if any, lubricate the ends of the clutch fork, the inside diameter of the release bearing and the input shaft. Position the release bearing over the input shaft; fit the fingers of the clutch fork onto the release bearing and over the pivot ball, engaging the fork onto the ball, with the spring clip being inserted through the clutch fork slot. Install the transaxle. As for the turbos, the process is the same but in the reverse with the addition of fitting the release cylinder and tightening the mounting bolts in three stages to the required torque before refitting the transaxle, coupling the hydraulic line and checking the brake fluid level in the company's reservoir and adding sufficient fluid until it meets the correct level.