My Garage

My Account

Cart

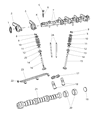

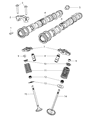

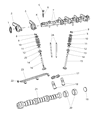

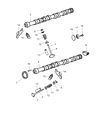

Genuine Dodge Grand Caravan Rocker Arm

Engine Rocker Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

13 Rocker Arms found

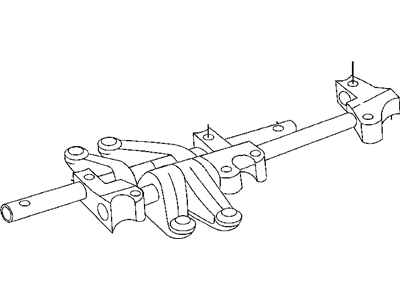

Dodge Grand Caravan Engine Rocker Arms

Part Number: 68027600AA$43.01 MSRP: $74.55You Save: $31.54 (43%)

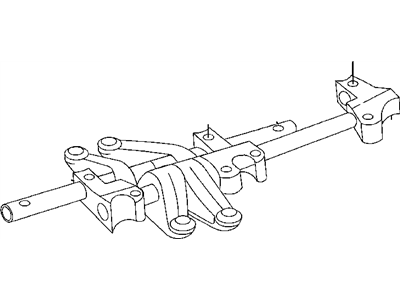

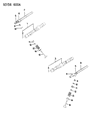

Dodge Grand Caravan Engine Intake Rocker Arm

Part Number: 4573460$44.32 MSRP: $90.25You Save: $45.93 (51%)

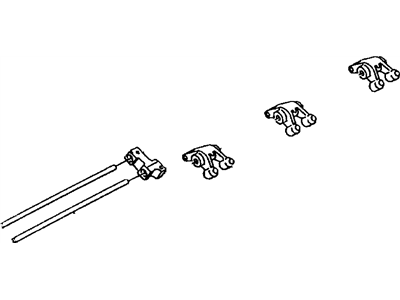

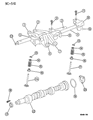

Dodge Grand Caravan Exhaust Rocker Arm

Part Number: 4663996$74.42 MSRP: $113.00You Save: $38.58 (35%)

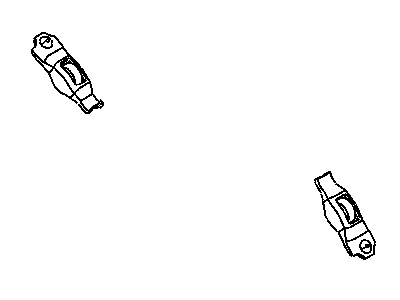

Dodge Grand Caravan Engine Intake Rocker Arm

Part Number: 4781183AA$90.01 MSRP: $134.00You Save: $43.99 (33%)

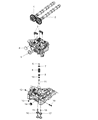

Dodge Grand Caravan Engine Rocker Arm

Part Number: 5184296AG$20.97 MSRP: $30.00You Save: $9.03 (31%)

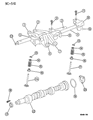

Dodge Grand Caravan Exhaust Rocker Arm

Part Number: 4781182AA$110.37 MSRP: $165.00You Save: $54.63 (34%)

Dodge Grand Caravan Rocker Arm

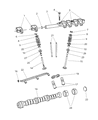

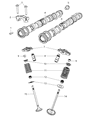

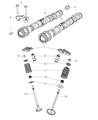

The Rocker Arm in Dodge Grand Caravan vehicles performs an important function of the valvetrain system where it provides motion to the intake or exhaust of the vehicles' engines. Usually made from stamped steel or aluminum the Rocker Arm is responsible for converting the up-and-down movement of the pushrod into the downward movement required to open the valves. For high RPM application aerospace aluminum is used, but in diesel applications cast iron or forged carbon steel is used due to its higher strength. Roller rockers, may be installed on the Dodge Grand Caravan models, or similar types: These are finer than normal kinds since they incorporate needle bearings to prevent them from rubbing on the camshaft. The rocker ratio which is standard in today's engines varied from 1.5:1 to 1.8:1 enabling the camshaft to lift more than before thereby improving the performance of the engine. Higher RPM engines also use enhanced fulcrum bearings to help in combating stress and to also enhance the durability of the Rocker Arm system for the Dodge Grand Caravan vehicles.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Grand Caravan Rocker Arm at great affordable prices. Moreover, all genuine Dodge Grand Caravan Rocker Arm come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Grand Caravan Rocker Arm Parts Questions & Experts Answers

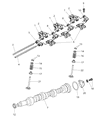

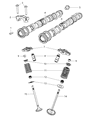

- Q: How do you remove and reinstall Camshaft,Lash Adjuster and Rocker Arm in 2.5L four cylinder engine on Dodge Grand Caravan?A:To further accessorize the valve cover, begin by unplugging the Timing Belt cover, timing belt, and camshaft sprockett; if you can use extra time, then unwind the camshaft sprockett and tether it with a wire, but it stays attached to the belt and has tension. Five bearing caps support the camshaft and are fastened with two bolts each ; these caps are numbered from 1 to 5 starting from the drivebelt side of the engine block; if such numeration is missing it is advisable to make some marks to facilitate reinstallation. Also, label the rocker arms as well as the lash adjusters for effectiveness during the time of reassembling the vehicle. Take out the bolts of all the bearing caps, but keep only numbers 2 and 4 tight, though loosened to take off strain on the valve springs. Any of the caps may stick and this should not be forced since it may damage the camshaft or housing, use a soft-face hammer to tap them into place. When the camshaft is removed and cleaned, then remove all the rocker arms and the lash adjuster and put them in bags with corresponding labels. For inspection it can be done by fixing camshaft with the help of caps 1 and 5, inserting a dial indicator and checking movement of the camshaft and compare it with specified value. To check camshaft runout, stand it and revolve it using V-block and, at the same time, observe the fluctuations of the indicator. Check journals and caps of the bearings for wear and change the parts if worn out and also consider the condition of the cam lobes, getting to the root cause of the worn out cam shaft. Rocker arms and hydraulic lash adjusters should be examined for their condition; before installing new parts, any problems with lubricants must be resolved. For installing, all the parts must be cleaned and the lash adjusters and the rocker arms must be lubricated before they can be placed in their respective positions as before. Coat lightly with a thin film of oil the camshaft bearing surfaces and proceed with the installation of the camshaft on the cylinder block making sure of its proper alignment. In this position, the extended part fits into the castellated seat of the bearing cap and the respective lube should be applied on the bearing cap and positioned before tightening in a progressive measure. It is advised that anaerobic-type sealant should be applied on the contact surfaces of the end caps and that the fasteners should be tightened in a star or cross fashion. Last but not the least, replace the camshaft sprocket, timing belt and such other components; to make certain that the valve timing is accurate, rotate the crankshaft two times after installing all these parts. In case, any resistance is felt while rotating it then the valve timing should be checked at once.

Related Dodge Grand Caravan Parts

Browse by Year

2020 Rocker Arm 2019 Rocker Arm 2018 Rocker Arm 2017 Rocker Arm 2016 Rocker Arm 2015 Rocker Arm 2014 Rocker Arm 2013 Rocker Arm 2012 Rocker Arm 2011 Rocker Arm 2010 Rocker Arm 2009 Rocker Arm 2008 Rocker Arm 2007 Rocker Arm 2006 Rocker Arm 2005 Rocker Arm 2004 Rocker Arm 2003 Rocker Arm 2002 Rocker Arm 2001 Rocker Arm 2000 Rocker Arm 1999 Rocker Arm 1998 Rocker Arm 1997 Rocker Arm 1996 Rocker Arm 1995 Rocker Arm 1994 Rocker Arm 1993 Rocker Arm 1992 Rocker Arm 1991 Rocker Arm 1990 Rocker Arm