My Garage

My Account

Cart

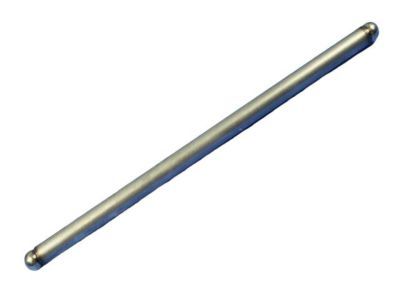

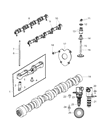

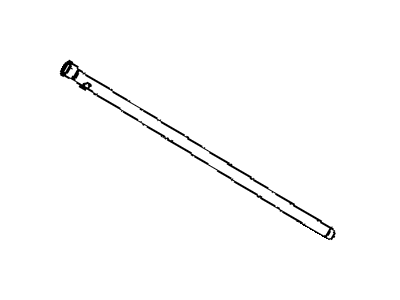

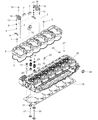

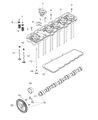

Genuine Ram 2500 Pushrod

Valve Push Rod- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Pushrods found

Ram 2500 Pushrod

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Ram 2500 Pushrod at great affordable prices. Moreover, all genuine Ram 2500 Pushrod come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

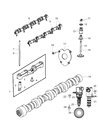

Ram 2500 Pushrod Parts Questions & Experts Answers

- Q: How to disassemble and inspect rocker arms and pushrods in diesel engine on Ram 2500?A:Disconnect the wires from the batteries at their negative terminals. Then remove the valve cover. Mark and detach the rocker arm/pedestal assemblies. Mark and take off crossheads. Pin down rocker arm sockets before raising them out of cylinder head. Mark and remove pushrods. Remove, clean with solvent, and disassemble rocker arms, pedestals, and shafts parts. Check for debris by blowing through oil passages. Get each rocker shaft bearing surface inspected for replacement if necessary.Measure each inside diameter of rocker arm bore against each outside diameter of rocker shaft and replace if worn too much.Check for cracks and scoring on all pushrod balls and ball seats, replacing any that are damaged.Look for damage or excessive wear on all crossheads in which case those affected should be replaced.Place the pushrods into position lubricate valve tips then put in place crossheads.Re-lubricate the bores , rockershafts then recapitulate the assembly of rockershaft/rockerarm/pedestal.Ensure lubrication of both crossheads as well as those sockets receiving a pushrod are done then fix a set of rockerarm/pedestal.The process ends by checking valve clearance.Installation of valve cover here may take place where it is not already installed.