My Garage

My Account

Cart

Genuine Chrysler Cirrus Clutch Fork

Release Fork- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Clutch Fork found

Chrysler Cirrus Clutch Fork

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Clutch Fork at great affordable prices. Moreover, all genuine Chrysler Cirrus Clutch Fork come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Clutch Fork Parts Questions & Experts Answers

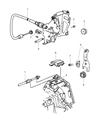

- Q: How do you remove and install Clutch Fork and Release Bearing on Chrysler Cirrus?A:Before removing the modular clutch assembly, the negative battery cable should be disconnected from the ground stud on the left shock tower and when handling the modular clutch assembly care must be taken to avoid dirtying the friction surfaces. While working on the transaxle, position the clutch fork and bearing at right angle to the input shaft, hold the clutch fork at both sides of the pivot ball socket and pull it to remove from the pivot stud without the use of screw driver that may cause the spring clips to be damaged. To dismantle, slide the bearing and the clutch fork off the bearing sleeve, and then take the fork out from the bearing but carefully such that the retention tabs are not destroyed. To test a bearing, grasp the outer race with your hand and turn the inner race applying pressure: the rotary motion should be smooth and noiseless, and if the bearing feels rough or noisy - it has to be replaced. Remove the bearing from the shaft and clean it with a cloth, do not immerse it in any solvent and check it for damages, signs of wears and cracks. Inspect the clutch fork for cracks or distortion and the pivot ball spring clips for damage, and replace them if required. Remove any debris from pivot ball and pocket at the end of the clutch fork: check for signs of wear. During installation, care should be taken not to lubricate the Teflon-coated pivot stud ball or its pocket: the clutch fork ends, the inner diameter of the bearing and the input shaft need to be lightly coated with hi-temperature grease. Snap the small pegs on the bearing over the fork arms before inserting this into the clutch fork before inserting the bearing and fork into the input shaft sleeve before snapping in the fork into its corresponding slot on the pivot ball of the modular clutch assembly.