My Garage

My Account

Cart

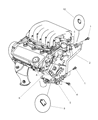

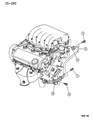

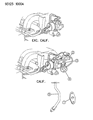

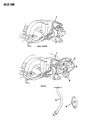

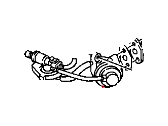

Genuine Chrysler Cirrus EGR Valve

Emissions EGR Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 EGR Valves found

Chrysler Cirrus EGR Valve

In Chrysler Cirrus it relieves back pressure from the engine exhaust and regulates the flow of exhaust gases back into the combustion chambler when the air-fuel ratio cannot be adequately maintained which in turn minimizes formation of air pollutants. This system has been made to reduce nitrogen oxide (NOx) emissions by the use of wasted gases which reduces the combustion temperatures and hence increase engine efficiency. There are models of Chrysler Cirrus that have employed different form of EGR Valve this ranges from the most simple orifice jets to the advanced valves that are capable of depending on engine conditions like the temperatures of the coolant and the existent manifold vacuum. The present day EGR systems may employ backpressure transducers that help it to vary the flow as per the load. Even though EGR does the job of maintaining emissions standards, some new engines such as the Chrysler Pentastar 3.6L engine do not come with EGR Valve. This piece will focus on EGR Valves because they may become laden with carbon deposits in Chrysler Cirrus vehicles and as such, require a regular service.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus EGR Valve at great affordable prices. Moreover, all genuine Chrysler Cirrus EGR Valve come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus EGR Valve Parts Questions & Experts Answers

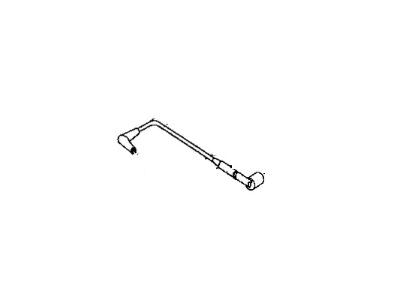

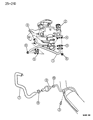

- Q: How do you diagnose and replace a faulty EGR valve on Chrysler Cirrus?A:If for some reason the EGR valve control solenoid gets disconnected or damaged then no electrical signal will be provided to shut the valve and thus due to the open valve during warm-up and other driving conditions there will be poor performance, rough idle & driveability problems. The EGA system decreases oxides of nitrogen (NOx) by rebreathing through the EGA valve some of the exhaust gases back into the intake manifold so as to lessen the maximum flame temperature during the process of combustion. EGA valve-EGA solenoid/transducer assembly, PCM, and sensors. By varying the position of the solenoid which controls the vacuum to the transducer, the EGA valve operates in response to the back-pressure in the exhaust system. When diagnosing the EGR valve, first examine all the hoses and tubes for signs of leakage and or damage, they should be whole. Disconnect the hose leading to the EGA valve and add a hand operated vacuum pump and start the engine and let it run to normal temperature. Make vacuum of about 5 in-Hg of the EGA valve; a large difference in the idle speed is an indicative of proper functioning. It the engine speed is constant, then it could be a damaged EGA valve or have blocked passage. After that, suck 15 in-Hg vacuum and if EGA valve stem responds, the valve is normal but if not, the valve has to be changed. Verify vacuum pressure and, if vacuum pressure is low or fluctuating after three minutes, the diaphragm could be bad; replace either the EGA valve or solenoid/transducer assembly. For the solenoid/transducer assembly, remove the electrical connector and vacuum hose then apply vacuum; if vacuum is felt then this assembly must be replaced. Power the solenoid with battery voltage and see if there is vacuum; if there is none, then change the assembly. Use vacuum on the transducer diaphragm; check if vacuum is retained; If the vacuum is not retained replace the EGR valve and Solenoid/transducer assembly. When removing, unclipped the electrical connector, and the hoses, and for V6 engines, stowed the Transmission Control Module away from the work area but no need to remove it. Disconnect the EGR tube and valve; clean the gasket surfaces, then, if there is too much carbon depositing, change the EGR valve and the solenoid/transducer. Reinstall the EGR valve and tube with new gaskets, tighten bolts to the proper torque then reinstall the TCM, reinstall the solenoid/transducer reconnect the hoses and electrical connectors.