My Garage

My Account

Cart

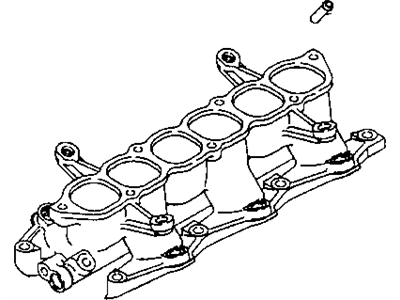

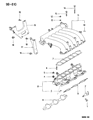

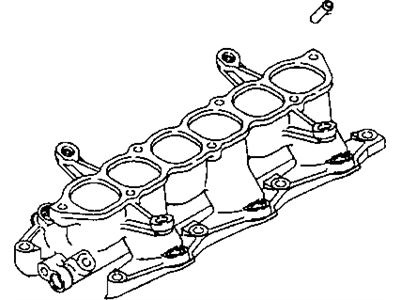

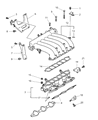

Genuine Chrysler Cirrus Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Intake Manifolds found

Chrysler Cirrus Intake Manifold

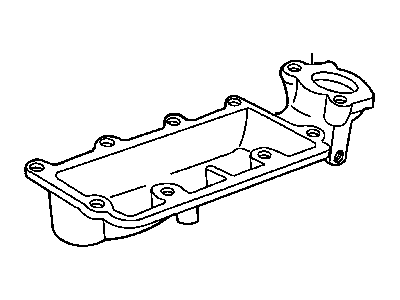

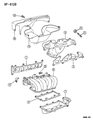

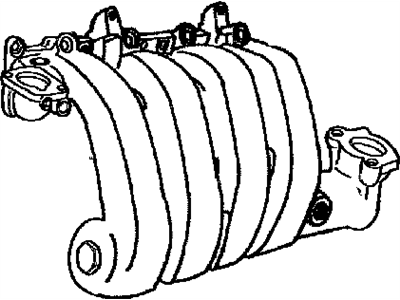

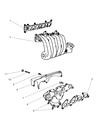

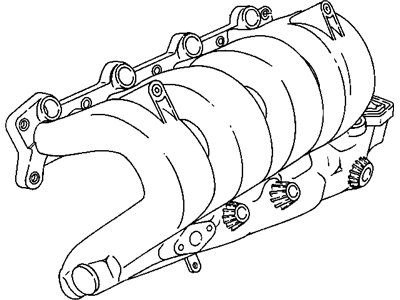

Intake manifold of Chrysler Cirrus automobile is responsible for supplying air or sometimes air fuel mixture to the cylinders in a car to enhance performance of the car engine. This is done by the use of specific designs in the style such as Variable Length Intake manifolds (VLIM), which determines the air volume and boosts power with the use of venturies and other resonators such as Helmholtz. Original Chrysler Cirrus intake manifolds were usually of cast iron or aluminum but now most automobiles uses lightweight composite plastics in their manifolds thus enhancing fuel efficiency and heat management. It often comprises pistons with independent heads linked by Gaskets, Coolants, and probe to measure the operation of an engine.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Intake Manifold at great affordable prices. Moreover, all genuine Chrysler Cirrus Intake Manifold come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Intake Manifold Parts Questions & Experts Answers

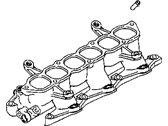

- Q: How do you remove and install the intake manifold in four cylinder engine on Chrysler Cirrus?A:To remove the intake manifold proceed through the following procedures, None the fuel system pressure and disconnect the negative battery cable from the ground stud at the hood of the left shock tower. Subsequently, take out the air cleaner assembly and neatly label, and detach all vacuum hoses and wires, brackets and emission hoses affiliated to the FI system, throttle body and intake manifold. Move to the removal of the fuel rail and injector assembly then the throttle body. Remove the fasteners in the transaxle-to-throttle body support bracket and reciprocate the transaxle side fastener but before performing this operation, ensure that all the electrical connections related to the support bracket are undone. Take out the mounting bolts at the EGA tube on the intake manifold end and EGR valve end. While on the engines of 2.0L, torque the water inlet tube support/intake manifold nut/bolt on the passenger side, while on 2.4L, remove the intake manifold support bracket from the driver's side. Lift off the clip, unscrew the intake manifold bolts and loosen it from the engine, always rounding the components and never driving through the heads of the fuel injector or marring the gasket contact area with a soft face hammer if required. For inspection, on 2.4L engines, remove all of the intake manifold gasket material from the surfaces of the cylinder head and the intake manifold alike, but do not dig deeply into the aluminum. On 2.0L engines, the O-ring seal gaskets of the intake port, and the throttle body should be pulled out; the intake manifold then checked for cracks or any sign of damage and replaced if faulty. The other measurements that ought to be made are the thickness of the mating surface of the intake manifold which should be checked with the use of a straightedge in conjunction with a feeler gauge: If warpage exceeds the recommended limits then the manifold has to be replaced or resurfaced. If there is need to replace the intake manifold, new bolts and washers are advised to be put on in the 2.0L engines. In the same manner of the removal, the intake manifold needs to be refitted with a new gasket or O-rings if necessary; the intake manifold bolts requires three-step tightening to conform to the specified torque; the rest of the procedures for installing the parts is in the reverse order of the removal.