My Garage

My Account

Cart

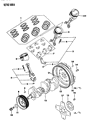

Genuine Chrysler Imperial Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Pistons found

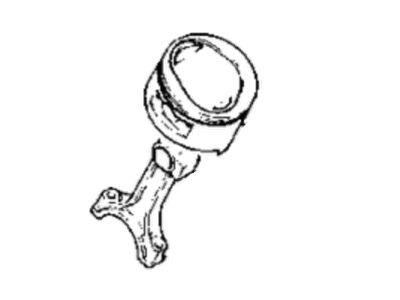

Chrysler Imperial Piston V6 W/PIN Std B

Part Number: MD119671$28.51 MSRP: $36.27You Save: $7.76 (22%)

Chrysler Imperial Piston

The Piston in Chrysler Imperial vehicles is one of the essential parts of the car that convertso the force produced by combustion into the mechanical force that is necessary to move the car. The function of this vital component of the internal combustion engine is to convert the pressure generated by expanding gases into movement whereby the crankshaft pulls the automobile. Chrysler Imperial Pistons are normally made from lighter metals/alloys mostly aluminum for the reasons of weight reduction and strength and while certain high performance vehicles may use Forged/billet pistons. The following are some of the Types of Pistons that has been used in Chrysler Imperial vehicles in the past years. Trunk pistons are used in petrol as well as in diesel engine and they are designed to support side forces and it consists of oil rings. In high speed Petrol engines, slipper pistons are used to lowering weight, help in balancing and enhance the efficiency. Every kind of Piston is created to bear certain pressures and temperatures to aid enhancement and service duration of Chrysler Imperial engines.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Imperial Piston at great affordable prices. Moreover, all genuine Chrysler Imperial Piston come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Imperial Piston Parts Questions & Experts Answers

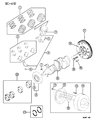

- Q: What steps should be taken to prepare piston/connecting rod assemblies for inspection and reassembly on Chrysler Imperial?A:The pistons/connecting rods cannot be inspected while still contained with the engine and therefore require cleaning and the removal of the original piston rings from the pistons to be replaced with new piston rings upon reassembly. Some of the cas uses include the following piston ring installation tool to cut out the old rings with out damaging the pistons in anyway. Get rid of all the carbon deposits you find on the top of the piston using the hand wire brush or fine emery cloth never use the wire brush that is mounted on the motor because this will lead to erasing of the surface finish of the softer material used on the construction of the Piston. Carbon deposits should be scraped out from the ring grooves using a piston ring groove cleaning tool and if this is not available, a piece of old ring can just as well be used, but care should be taken not to remove any metal or damage the grooves. After the deposits have been removed, wash out the piston/rod assemblies between solvent and dried with compressed if available. If the pistons and cylinder walls arent skint or worn too thin and if the engine block is not rebored new pistons may not be required; but new piston should always be fitted when an engine is being rebuilt. The skirt, pin bosses, and ring lands of each piston should be checked for cracks, while scoring, scuffing and any holes on the piston crown and burned areas on the edge of the crown which could be as a result of overheating or any abnormal combustion should also be checked for. Pitting corrosion means that there is a leakage of coolant into the combustion chamber or crankcase which must be rectified. Piston ring side clearance must be measured by installing a new piston ring to each groove and then using the feeler at different sections on the groove bearing in mind, each groove take the right ring. Engine bore wear can be checked by measuring the bore and piston diameter of the particular engine at the cylinder that depends on the type of the engine; if the piston to bore clearance goes beyond certain levels, this will require reboring of the block and new pistons and rings. Piston-to-rod clearance can be determined by rotating them in opposite directions, where significant looseness means there is wear and need for adjustment that may mean that the piston, rod and pins may have to be taken to an automotive machine shop for resizing. If pistons have to be pulled off the connecting rods, these should also be taken to the machine shop to check them for bend and twist, while the connecting rods should be examined for cracks and damage; old bearing inserts should also be temporarily removed for cleaning before reassembly.