My Garage

My Account

Cart

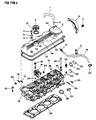

Genuine Chrysler Laser Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Cylinder Heads found

Chrysler Laser Head-Cylinder-Partial

Part Number: 4387614$592.80 MSRP: $867.00You Save: $274.20 (32%)

Chrysler Laser Cylinder Head

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Laser Cylinder Head at great affordable prices. Moreover, all genuine Chrysler Laser Cylinder Head come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Laser Cylinder Head Parts Questions & Experts Answers

- Q: What steps should be taken for thorough cleaning and inspection of the cylinder head and valve train components during an engine overhaul on Chrysler Laser?A:Cleaning of cylinder head and other associated components of the valve train after which you will be in a better position to determine as to much valve service will be required during the engine rebuild. Start by removing all the residues of the gasket material and the sealing compound from the head gasket, the intake and the exhaust manifolds sealing surfaces without scratching the cylinder head. Scrape any deposits of scale around to around the coolant passages and wire brush the holes and the ports of the EGR gas. Depress the suitable size tap to every the threaded hole to expunge blurring and thread sealant and then use clogged air to wash. Using a die clean the exhaust and intake manifold stud threads and using a wire brush clean the rocker arm pivot bolt or stud threads. Wash the cylinder head using solvent and, after washing it, ensure that it dries up, possibly by use of compressed air to hasten the process. Chait and Jones' concept of decarbonising chemicals may be useful but must be employed sparingly. Rocker arms and hydraulic lash adjusters should be cleaned with solvent and it's important that they be dried. Shake all valve springs, keepers and retainers together and remove heavy deposits on the valves by scraping them and brushing off the rest with a motorised wire brush. Check the head for cracks, leaks, etc.; if there are cracks on the head, then one has to purchase a new one. The camshaft bearing surfaces should be checked for galling or scoring, if they are badly damaged, the head has to be replaced or the crank will seize. For the functional head gasket mating surface confirmations, apply on straightedge and feeler gauge to determine if it is warped and if yes it needs to be resurfaced. Check the valve seats for pitting cracking or burn-- If the conditions are present-- The vehicle needs a valve job at an automotive machine shop. Use a dial indicator to measure the clearance between the valve stem and the valve guide and if there is uncertainty as to the condition of the valve guides, the checks should be done by a machine shop. Each rocker arm should be examined with respect to the degree of wear and tear, galling and pitting while that of the lash adjuster contact surface. Check the camshaft bearing journals for wear and galling and if worn both the camshaft and cylinder head will contain a new one. To retain on cam lobes, grooved the cam lobes and measure height and prototype with cam lobes specification; if less than minimum height or grooved then order a new camshaft. Examine each face of a valve and check for crack signs, pits and burned spots for the body of the valve, and also for any crack at the stem and the neck of the valve where bending is not allowed. Take the thickness of the valve margin with the dial calipers and check it against the specifications; any valve recorded to have margin less than the specifications must be replaced. Examine each valve spring for wear and surface pitting, and also for determining if its free length is correct: any spring which is too short should not be re-used. Check the condition of the spring retainers and keepers for any signs, of wear and cracks or damages should be replaced so that during the operation of the engine only small damages will occur. If the inspection shows that the valve components are bad, actually worn out and beyond limits then remove the valves and reassemble them back to the cylinder head for further servicing advice. In case no badly worn out parts are observed and that the valve faces and seats are good, then the valve train components may be reused without requiring extensive work.