My Garage

My Account

Cart

Genuine Chrysler PT Cruiser Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Oxygen Sensors found

Chrysler PT Cruiser Oxygen Sensor

Part Number: 56029049AA$103.50 MSRP: $154.00You Save: $50.50 (33%)

Chrysler PT Cruiser Oxygen Sensor

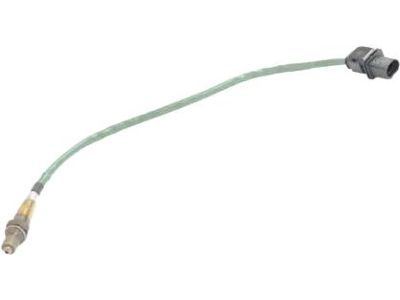

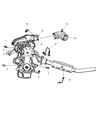

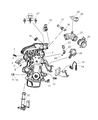

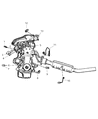

The Oxygen Sensor is an important component located in Chrysler PT Cruiser vehicles which is responsible to measure the flow of unburned oxygen being emitted in the exhaust so that the engine control computer can adjust the air-fuel mixture ratio for higher efficiency and less emissions. Through this voltage signal proportional to oxygen concentration, the sensor allows the engine to work in 'closed loop' which is important to sustain the efficiency of the catalytic converter. As for the Chrysler PT Cruiser variants, it is quite probable that they enlisted zirconium dioxide oxygen sensors with a possibility of both the narrow-band and the wide-band variants. The narrow-band sensors output provide cycling rich/lean signals and on the other hand, the wide-band sensors give continuously varying signals of air-fuel mixtures. At times, these sensors may wear out owing to contamination and hence cause emissions of more fuel and reduced fuel efficiency.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler PT Cruiser Oxygen Sensor at great affordable prices. Moreover, all genuine Chrysler PT Cruiser Oxygen Sensor come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler PT Cruiser Oxygen Sensor Parts Questions & Experts Answers

- Q: What special care is essential when servicing an oxygen sensor or air/fuel ratio sensor on Chrysler PT Cruiser?A:Particular caution needed when working on an oxygen sensor or air/fuel ratio sensor because the pigtail and electrical connector are always integrated; if they are damaged the sensor must be replaced. The electrical connector and the louvered end of the sensor must not be greased, must not accumulate dirt and other contaminants and only mild detergents must be used while cleaning these sensors. Furthermore, do not drop the sensors or handle them roughly, also make sure the blue silicone boot is properly fixed in place so it will not melt and so that the sensor works properly. For replacement, know that the nut on an oxygen sensor may seize up when the engine is cold, so one has to start the engine for a while. First of all ensure you have separated the wire from the negative terminal and then safely lifted the car on jackstands. The upstream oxygen sensor is mounted on top of the exhaust manifold and can be removed by pulling on the electrical connector and loosening the sensor with a unique socket and if the old sensor is being reinstalled the threads of the sensor bore should be cleaned and the sensor threads should be coated in anti seize compound and this obviously does not apply to new sensors. The downstream oxygen sensor procedure is the same to the upstream oxygen sensor that is on the left side of the top of Catalytic Converter, and that involves removing and disconnecting the electrical lead, removing the sensor, and then cleaning the threads of the sensor; if you are reusing the old sensor apply anti-seize compound before putting the sensor in. Lasty, add the downstream sensor and make sure that it is properly fixed by tightening it, proceeding in the reverse sequence.