My Garage

My Account

Cart

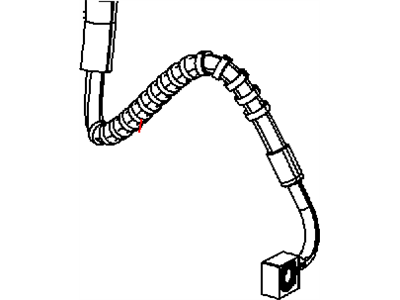

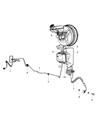

Genuine Chrysler Town & Country Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

150 Brake Lines found

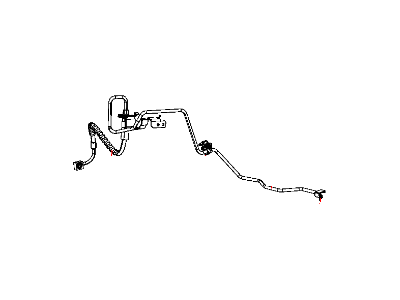

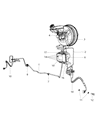

Chrysler Town & Country Brake Tube

Part Number: 5154220AD$113.63 MSRP: $171.00You Save: $57.37 (34%)Chrysler Town & Country Brake Tube

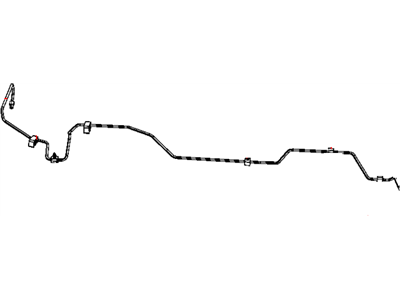

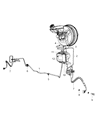

Part Number: 5154220AA$113.63 MSRP: $171.00You Save: $57.37 (34%)Chrysler Town & Country Brake Line

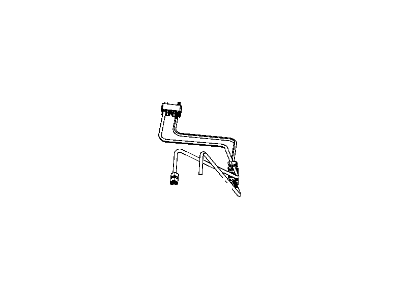

Part Number: 4721325AC$121.50 MSRP: $181.00You Save: $59.50 (33%)Chrysler Town & Country Brake Line

Part Number: 4721324AB$177.75 MSRP: $265.00You Save: $87.25 (33%)

| Page 1 of 8 |Next >

1-20 of 150 Results

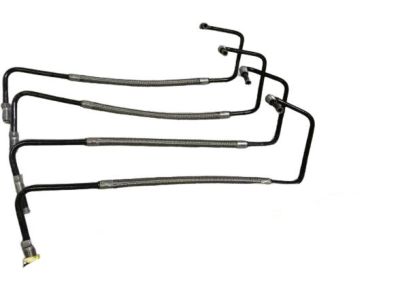

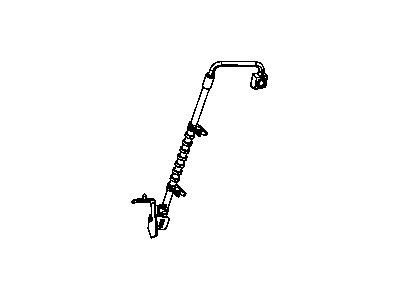

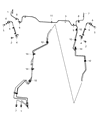

Chrysler Town & Country Brake Line

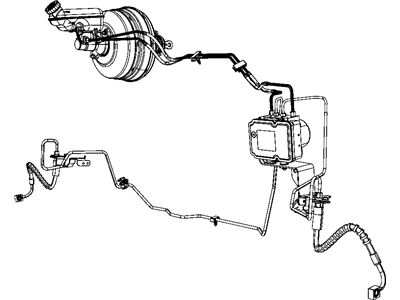

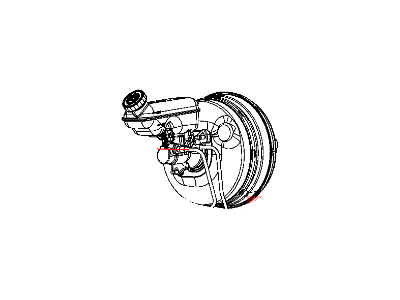

The Brake Line in Chrysler Town & Country vehicles services in supplying brake fluid from the master cylinder to brake caliper pistons, so that the hydraulic brake system should work efficiently. This system plays vital role for safe stopping and slowing of the vehicle on any type of surface. Chrysler Town & Country for years has incorporated Metal Brake Line and Rubber Brake Hoses as parts of this lorry. Metal brake lines are attacked by corrosion particularly during winter which causes formation of pin holes and consequent leakage of hydraulic pressure. However, rubber brake hoses can be damaged physically, internally limited or swollen all of which affects brake power. For enhanced performance we can up grade the Brake Line to a braided stainless steel where the improvement in the pedal feel and response is easy to experience especially when involved in spirited driving. Preformed brake components and brake line kits as well as direct replacement hoses intended for Chrysler Town & Country vehicles are easier to install and replace.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Town & Country Brake Line at great affordable prices. Moreover, all genuine Chrysler Town & Country Brake Line come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Town & Country Brake Line Parts Questions & Experts Answers

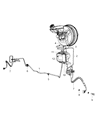

- Q: How to inspect and replace rubber hoses and metal brake lines on Chrysler Town & Country?A:Whenever the vehicle is raised and securely supported on jackstands, inspect the rubber hoses that connect the steel brake lines to the front and rear brake assemblies for cracks, chafing of the outer cover, leaks, blisters, and other damage. Use a light and mirror for a thorough check. If any hose exhibits these conditions, replace it immediately. To replace the flexible hose, clean all dirt away from the hose and line fittings. Using a flare-nut wrench, disconnect the metal brake line from the hose fitting and plug the metal line to prevent leakage and contamination. Remove the brake hose bracket/fitting assembly by removing the mounting bolt. Unscrew the banjo bolt at the caliper and remove the hose, discarding the sealing washers. Attach the new brake hose to the caliper using new sealing washers and tighten the banjo bolt. Attach the brake hose bracket/fitting assembly to the vehicle, ensuring the hose isn't kinked or twisted. Connect the metal line to the hose fitting, tightening securely. Check that the suspension or steering components do not make contact with the hose. Check the master cylinder fluid level and add fluid as necessary. Bleed the brakes and test brake operation before resuming normal operation. When replacing metal brake lines, use the correct parts and avoid using copper tubing. Prefabricated brake lines with flared tube ends and fittings can be bent to the proper shapes using a tubing bender. Ensure the new line is well supported in the brackets and has sufficient clearance. Tighten the fittings securely. Check the master cylinder fluid level, bleed the brakes, and test brake operation before resuming normal operation.

Related Chrysler Town & Country Parts

Browse by Year

2016 Brake Line 2015 Brake Line 2014 Brake Line 2013 Brake Line 2012 Brake Line 2011 Brake Line 2010 Brake Line 2009 Brake Line 2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line 2003 Brake Line 2002 Brake Line 2001 Brake Line 2000 Brake Line 1999 Brake Line 1998 Brake Line 1997 Brake Line 1996 Brake Line 1995 Brake Line 1994 Brake Line 1993 Brake Line 1992 Brake Line 1991 Brake Line 1990 Brake Line 1988 Brake Line 1987 Brake Line 1986 Brake Line 1985 Brake Line 1984 Brake Line