My Garage

My Account

Cart

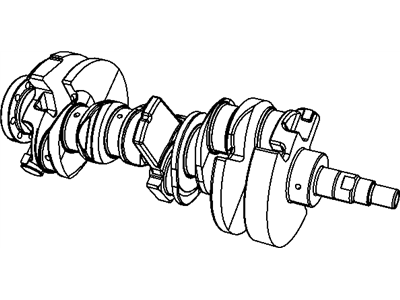

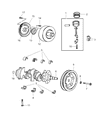

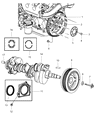

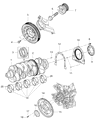

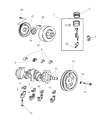

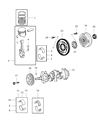

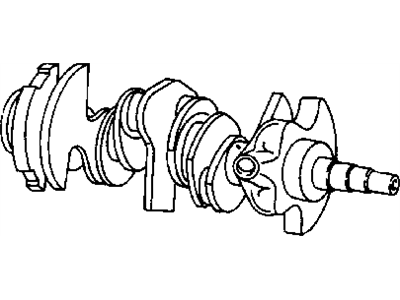

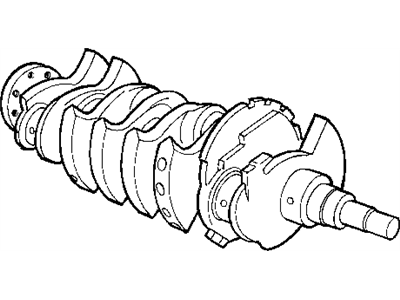

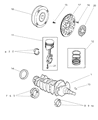

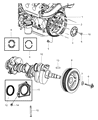

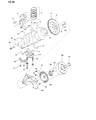

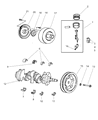

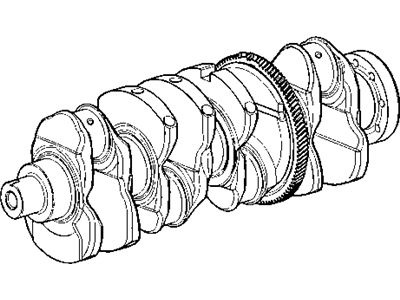

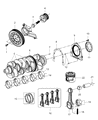

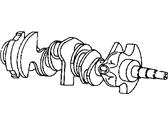

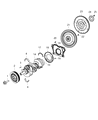

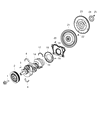

Genuine Chrysler Town & Country Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Crankshafts found

Chrysler Town & Country CRANKSHFT

Part Number: 5184251AG$567.60 MSRP: $860.00You Save: $292.40 (34%)

Chrysler Town & Country CRANKSHFT

Part Number: 5184251AH$567.60 MSRP: $860.00You Save: $292.40 (34%)Chrysler Town & Country CRANKSHFT

Part Number: 4781643AA$536.70 MSRP: $818.00You Save: $281.30 (35%)Chrysler Town & Country CRANKSHFT

Part Number: 5184251AF$567.60 MSRP: $860.00You Save: $292.40 (34%)Chrysler Town & Country CRANKSHFT

Part Number: 4621983AD$298.65 MSRP: $1045.00You Save: $746.35 (72%)Chrysler Town & Country CRANKSHFT

Part Number: 4781071AB$1774.10 MSRP: $2635.00You Save: $860.90 (33%)Chrysler Town & Country CRANKSHFT

Part Number: 4781071AC$1774.10 MSRP: $2635.00You Save: $860.90 (33%)Chrysler Town & Country CRANKSHAF

Part Number: 68158311AA$1197.80 MSRP: $1770.00You Save: $572.20 (33%)Chrysler Town & Country CRANKSHFT

Part Number: 4621983AB$706.25 MSRP: $1045.00You Save: $338.75 (33%)

Chrysler Town & Country Crankshaft

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Town & Country Crankshaft at great affordable prices. Moreover, all genuine Chrysler Town & Country Crankshaft come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Town & Country Crankshaft Parts Questions & Experts Answers

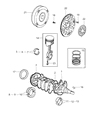

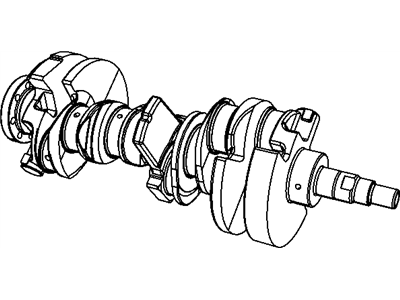

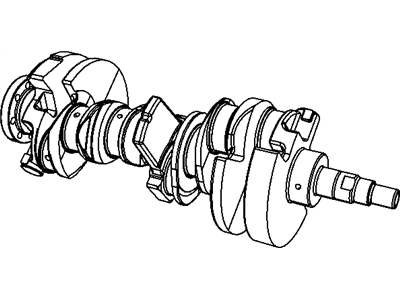

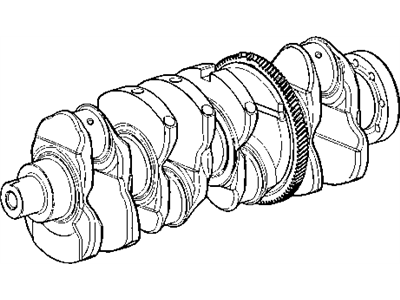

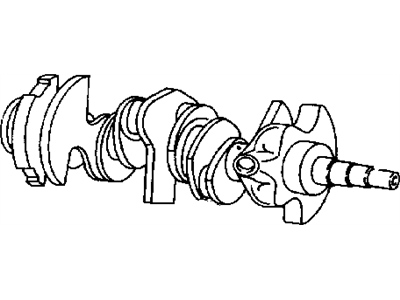

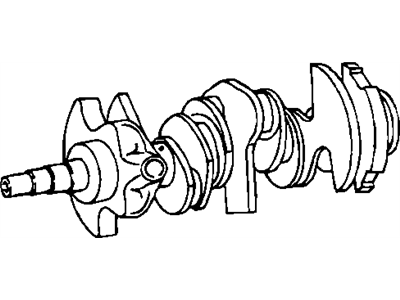

- Q: How can the crankshaft be removed and reinstalled on Chrysler Town & Country?A:The crankshaft can only be removed with the engine being pulled out of the car provided several other parts have been removed; these are the flywheel, crankshaft pulley, timing belt/chain, oil pan, oil pump body, oil filter, and the piston/connecting rods. Before spiking out the crank shaft, put the dial indicator in contact with the crank shaft to determine the crank shaft end play. With the crankshaft pushed to the rear, slightly rotate the indicator tip until the pointer reads zero, then push the crankshaft to the front, read the indicator which should be in the range of 0.003 to 0.010 inch. A dial indicator may not be available and the use of feeler gauge is acceptable in order to get the clearance. Unthread the bedplate or main bearing cap screws progressively and then gently use a hammer to knock it off if you cannot lift it off by hand but be careful not to drop the bearing inserts. Slowly raise it right up, preferably with help, and replace the beds or mains with the arrow pointing towards the front of the engine. For installation say the engine block and the crank shaft have to be clean and have to be inspected. Place the block in an inverted manner in the hole, and if there are any ready-made bearing inserts present they must be withdrawn and the area scrubbed. New upper main bearing inserts should be fitted and correct position of oil holes for them, the correct journal position of the thrust washer. Scrape and deglaze the crankshaft and bearing surfaces then set the crankshaft in position. Feel the main bearing oil clearance with the help of Plastigage and do not take apart the assembly. After this tighten the bolts as per the sequence shown above and then take out the assembly in order to check the width of the Plastigage for the clearance. If it is necessary remove bearing inserts to have correct clearance. Remove any of the Plastigage deposits and put a new thin layer of the grease on the bearing surfaces and replace the crankshaft. Check that the engine block is clean and apply anaerobic sealant, if necessary. Place the principal bearing assembly in correct position and tighten the bolts in sequence. Ensure that the crankshaft end play is correct; turn the crankshaft clockwise and anti clockwise and ensure it does not bind. Last but not the least, fit the new rear main oil seal.

Related Chrysler Town & Country Parts

Browse by Year

2016 Crankshaft 2015 Crankshaft 2014 Crankshaft 2013 Crankshaft 2012 Crankshaft 2011 Crankshaft 2010 Crankshaft 2009 Crankshaft 2008 Crankshaft 2007 Crankshaft 2006 Crankshaft 2005 Crankshaft 2004 Crankshaft 2003 Crankshaft 2002 Crankshaft 2001 Crankshaft 2000 Crankshaft 1999 Crankshaft 1998 Crankshaft 1997 Crankshaft 1996 Crankshaft 1995 Crankshaft 1994 Crankshaft 1993 Crankshaft 1992 Crankshaft 1991 Crankshaft 1990 Crankshaft 1988 Crankshaft 1987 Crankshaft