My Garage

My Account

Cart

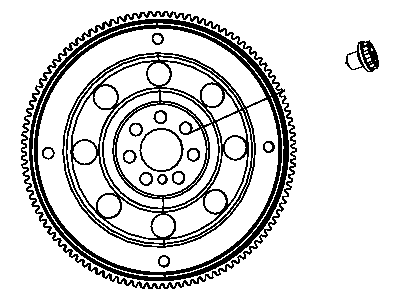

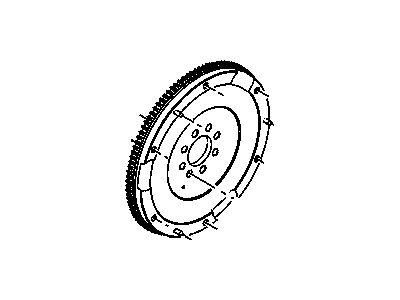

Genuine Dodge Avenger Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Flywheels found

Dodge Avenger Flywheel

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Avenger Flywheel at great affordable prices. Moreover, all genuine Dodge Avenger Flywheel come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

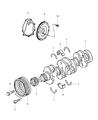

Dodge Avenger Flywheel Parts Questions & Experts Answers

- Q: How do you remove and reinstall the driveplate in 3.6L V6 engine on Dodge Avenger?A:To cause the driveplate to be removed first, lift the vehicle and place it on jackstands. Next, remove the transaxle. While removing and reassembling the plates align them so when you reassemble the driveplate, and the backing plate look for the match-marks on the crankshaft and align it as they were initially. All bolts that hold the driveplate to the crankshaft have to be removed, noting the orientation of the part before removing the bolts, and then, when loosening the bolts, using a specific tool to keep a hold on the driveplate. Another method is to get a special tool from any auto parts store; in the absence of which a screwdriver will suffice as it is inserted in the teeth of the starter ring gear then dropped to jam the drive plate. Lever out the driveplate but hold it during the final removal of the last bolt, remove grease and oil dirt on the surface of the plate and examine it for signs of wear or damage. Ensure surfaces for mating of driveplate with crankshaft are clean and spotless and in case the rear main seal of the crankshaft is worn and is leaking, it should be replaced before replacing the driveplate. For assembly, locate the outer/inside surface of the driveplate and backing plate respectively to the crankshaft, depending on the machining marks of match marks and apply thread lock on the thread of bolt to be used. Since it is hard to rotate it when re-installing, hold the driveplate with the holding tool or, better still, wedge the blade of a flathead screwdriver between the starter ring gear teeth to lock it in place then tighten the bolts to the prescribed torque. As such, the rest of the installation is done in the reverse order of removal.