My Garage

My Account

Cart

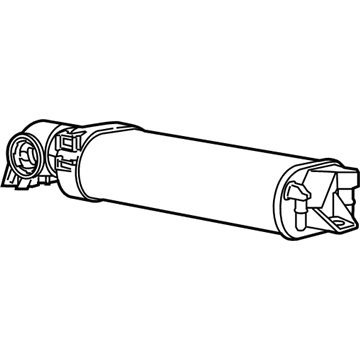

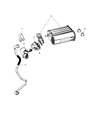

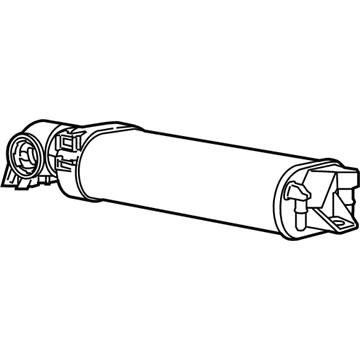

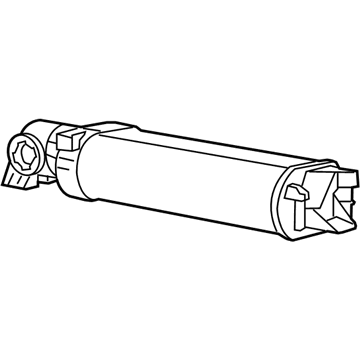

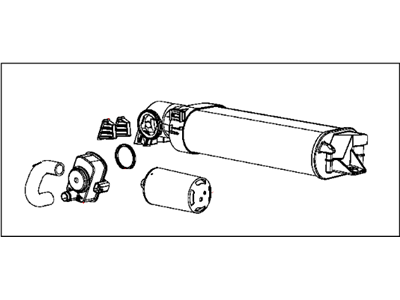

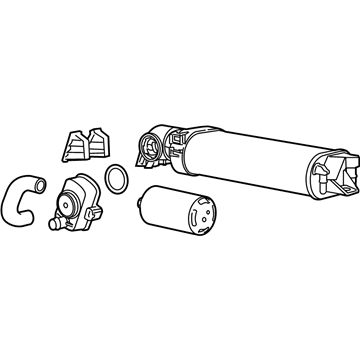

Genuine Dodge Challenger Vapor Canister

Fuel Vapor Canister- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Vapor Canisters found

Dodge Challenger Vapor Canister

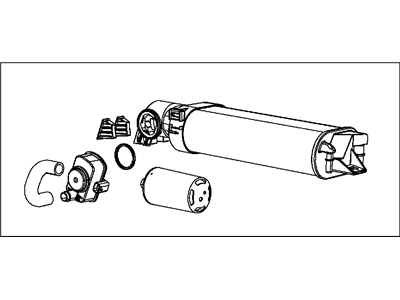

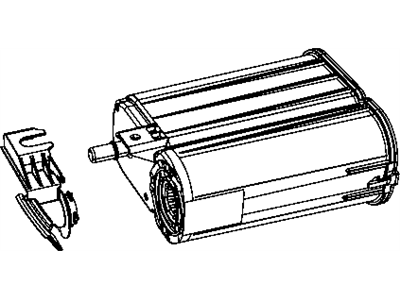

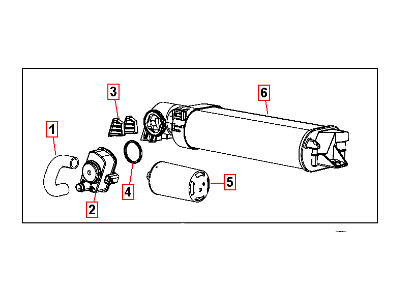

The Vapor Canister in Dodge Challenger vehicles or actually known as the EVAP or charcoal canister is an important factor in reducing carbon vapors as well as in the efficiency of fuel. This gadget forms part of the EVAP system which collects fuel vapour from the fuel tank and emits it any time the engine calls for fuel. Even, the Vapor Canister of Dodge Challenger mostly need the cleaning activity but if the condition gets severe and the cracking causes dangerous internal pressure then it is required to replace them in order to avoid accidental situation like fire and explosion. Through the years, different styles of Vapor Canisters may have been installed in different Dodge challenger models wherein the major difference lies in the looks and performance in holding and preserving the fuel vapors. The Vapor Canister requires constant check-ups, and when necessary, it has to be replaced so that the vehicle does not pose any threat to the safety of the users.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Challenger Vapor Canister at great affordable prices. Moreover, all genuine Dodge Challenger Vapor Canister come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Challenger Vapor Canister Parts Questions & Experts Answers

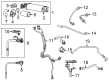

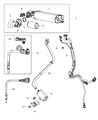

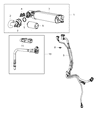

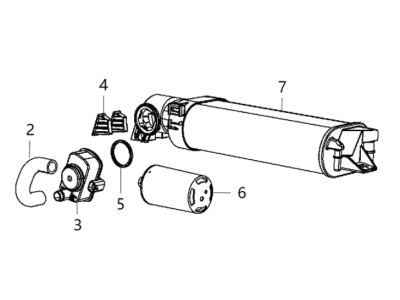

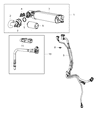

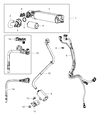

- Q: What is the function and operation of the Evaporative Emissions Control system,Canister Purge Valve and Canister on Dodge Challenger?A:The Evaporative Emissions Control (EVAP) is the system which controls emission of fuel system vapors, which contain We, unburned hydrocarbons. During hot days, gases formed within the fuel tank build upon the fuel and when pressure builds up, the fuel vapour vent valve and the fuel vapour control valve directs the fuel vapours to the EVAP canister for a temporary storage until it is burnt by the engine. In certain circumstances, PCM turns on fuel canister purge solenoid and with the help of intake manifold vacuum, fuel vapour enters into induction air/fuel mixture to supply for combustion. EVAP canister is installed in the right rear corner of the automobile and it is of activated charcoal type which does not require any service. The Natural Vacuum Leak Detection (NVLD) assembly located in the same area, is designed to measure the temperature of unburned hydrocarbon vapours; if the pressure temperature relationship is abnormal then it sends a signal to the PCM to set a Diagnostic Trouble Code (DTC). The canister purge solenoid controls the flow of the vapor from the canister to the intake manifold and this is controlled by the PCM. A defective EVAP system shows some symptoms such as a strong smell of fuel especially in a hot climate; there may be a problem with the filler cap, the hoses connections or the canister. On component replacement, the electrical connectors are disconnected, hoses get labeled and several components are removed whilst on installation it is just the opposite of removal. For the 2007 and later models, the EVAP filter and the Evaporative Emission System Monitor (ESIM) are an integrated part of the canister in the car and the Fuel Tank Pressure (FTP) sensor is in the fuel tank vent tube which, similar to the above explained, has to be disconnected to check.

Related Dodge Challenger Parts

Browse by Year

2023 Vapor Canister 2022 Vapor Canister 2021 Vapor Canister 2020 Vapor Canister 2019 Vapor Canister 2018 Vapor Canister 2017 Vapor Canister 2016 Vapor Canister 2015 Vapor Canister 2014 Vapor Canister 2013 Vapor Canister 2012 Vapor Canister 2011 Vapor Canister 2010 Vapor Canister 2009 Vapor Canister 2008 Vapor Canister