My Garage

My Account

Cart

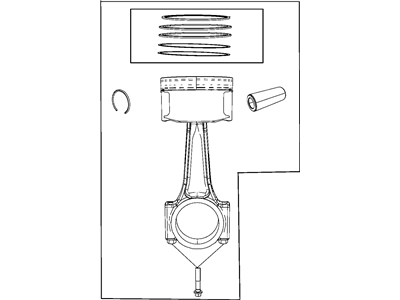

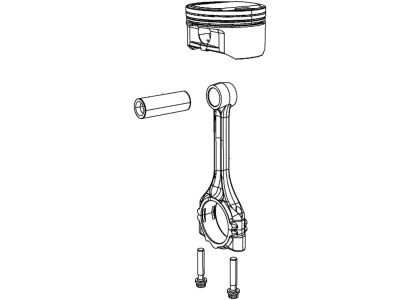

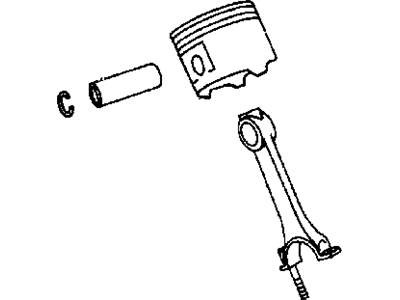

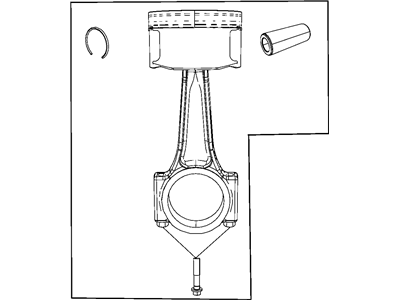

Genuine Dodge Charger Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Pistons found

| Page 1 of 2 |Next >

1-20 of 26 Results

Dodge Charger Piston

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Charger Piston at great affordable prices. Moreover, all genuine Dodge Charger Piston come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

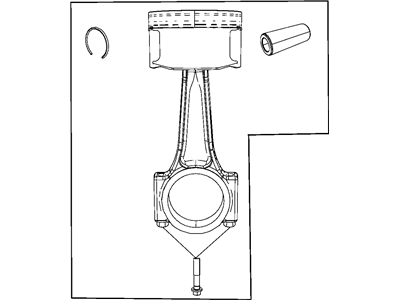

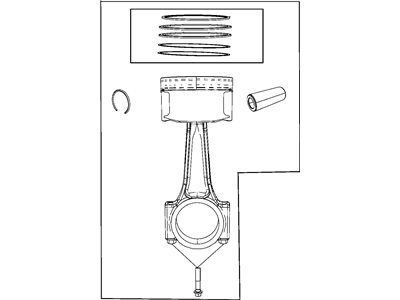

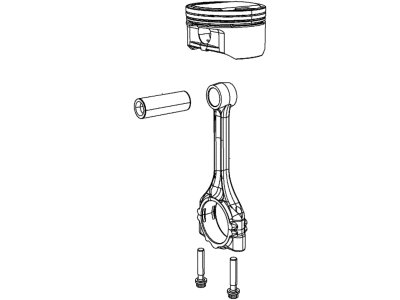

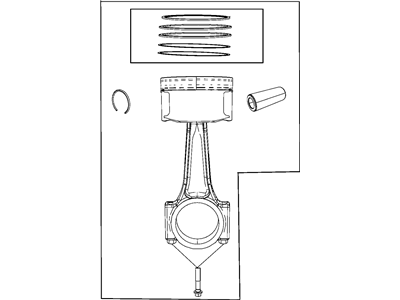

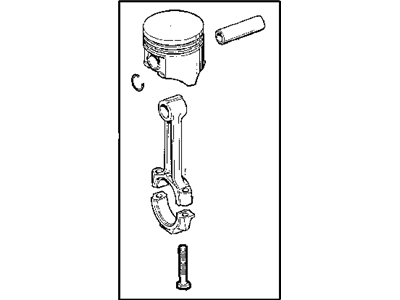

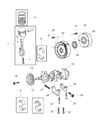

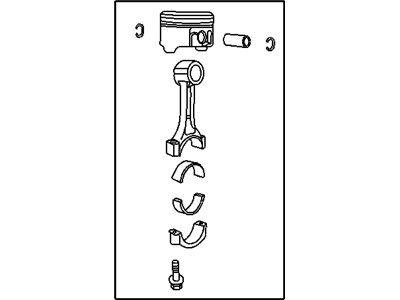

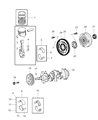

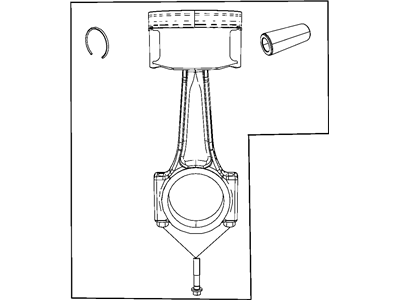

Dodge Charger Piston Parts Questions & Experts Answers

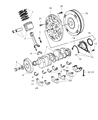

- Q: How to remove and reinstall piston/connecting rod assemblies on Dodge Charger?A:Get rid of any grooves at the top ring travel limit before removing piston/ connecting rod assemblies if there are any. Position the engine in relation to the Crankshaft such that the crankshaft faces upwards. Use a feeler gauge to determine whether there is adequate play between the parts and, if not, consult an automotive machine shop. Make sure you mark all the rods and caps for identification purposes. Loosen bolts on connecting rod cap then take off the cap and bearing insert. Push out connecting rod/piston assembly through top of engine. Repeat for other cylinders. Fasten down with finger tight bearing inserts and reassemble rod caps. Check ring end gap on pistons then set if necessary. Fit rings into position starting with oil control ring." Last sentence is: Ensure smooth rotation of upper and lower side rails." Put in place middle and top rings." Clean cylinder walls thoroughly; chamfer upper edge of each cylinder bore." Put back piston/connecting rod assemblies having ensured that front mark on piston is facing toward front of engine" "Tap cylinder using hammer handle as piston enters it." Check connecting rod bearing oil clearance with Plastigage while greasing or applying engine assembly lube to bearing faces then reinstall rod caps." Repeat for other pistons/connecting rods". Turn crankshaft manually to test for binding; re-examine play between connecting rods after this process".