My Garage

My Account

Cart

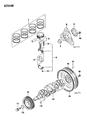

Genuine Dodge Colt Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

Dodge Colt Crankshaft

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Colt Crankshaft at great affordable prices. Moreover, all genuine Dodge Colt Crankshaft come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Colt Crankshaft Parts Questions & Experts Answers

- Q: What steps should be taken to inspect and regrind a crankshaft, and how is the endfloat checked on Dodge Colt?A:Examine the crankpin and main journal surfaces for signs of scoring or scratches, and check the ovality of the crankpins at different positions with a micrometer; if more than 0.001 in (0.03 mm) out of round, the crankpin will need to be reground, as will any that show scores or scratches. Journals should be checked in the same manner. If regrinding the crankshaft and fitting new bearings is necessary, a local dealer or engineering works can determine how much metal to grind off and the size of new bearing shells. Full details of crankshaft regrinding tolerances and bearing undersizes are available. Temporarily refit the crankshaft to the crankcase after placing the upper halves of the shell main bearings in their locations, then fit the centre main bearing cap with the shell bearing and tighten the securing bolts to 50 lbf ft (68 Nm). Use a feeler gauge to check the endfloat by pushing and pulling the crankshaft; if the endfloat is outside the specified tolerance, renewing the shells will typically correct it. Finally, examine the input shaft bearing in the centre of the Flywheel on 1597 cc models, and if it is worn, a new one will need to be fitted.