My Garage

My Account

Cart

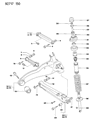

Genuine Dodge Colt Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Shock Absorber found

Dodge Colt Shock Absorber

In the field of automobile, the Shock Absorber, particularly on Dodge Colt automobiles, is an important component system whose main function is to minimize shock impulses in order to obtain a better quality of ride and control on the road. The Shock Absorber further transform kinetic energy to heat thus reducing the bouncing and vibrations while on the bumpy ground. Shock Absorbers that has been used by Dodge Colt models in the past years includes twin-tube Shock Absorbers and mono-tube Shock Absorbers. Twin-tube shocks are also prevalent, with basic construction that can be gas filled in order to increase the density. Mono-tube shocks are the superior ones when it comes to heat transfer and performance coupled with multi-axial capability. There are more specialised types such as Position Sensitive Damping (PSD) and Acceleration Sensitive Damping (ASD) as the name suggests defines the way a Shock Absorber works in accordance to the conditions in which the Dodge Colt is being driven.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Colt Shock Absorber at great affordable prices. Moreover, all genuine Dodge Colt Shock Absorber come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Colt Shock Absorber Parts Questions & Experts Answers

- Q: How do you replace or repair strut on Dodge Colt?A:With the strut removed from the car, clean away external dirt. The coil spring must now be compressed, and suitable compressors can be obtained from most motor accessory stores. With the spring compressed, hold the spring upper seat with a special tool while the nut at the top of the strut piston rod is unscrewed. Remove the spring upper seat, the spring (still compressed), and the bump rubber. A choice is now available before proceeding; if the unit is simply leaking fluid, it can be repaired, but if it is badly worn after high mileage, it can be renewed (less spring and upper mounting) or a cartridge insert can be fitted according to the manufacturer's instructions. Secure the strut vertically in a vice, then use a pin wrench or special tool to unscrew the gland nut from the top of the strut. Drain the fluid and discard the small square section sealing ring. Slowly withdraw the piston rod/guide out of the tubular casing of the strut. Repair kits are available to include some or all of the dismantled items as wear dictates the need. Observe absolute cleanliness during reassembly and apply clean fluid to all components as they are refitted. Fit the piston rod into the cylinder and then fit the piston/cylinder into the strut casing. Fill the strut with 240 cc of shock absorber fluid, doing this slowly while moving the piston rod up and down to allow trapped air to escape. Fit the piston guide and a new square section seal. Tape over the threads of the piston rod to prevent damage to the lips of the oil seal nut, then screw in the nut until it makes metal to metal contact with the strut tube. Fit the compressed spring, the bump rubber, the spring seat, the insulator, and the washer. Align the D-shaped hole in the spring seat correctly with the piston rod. Hold the spring upper seat with the special tool and tighten the self-locking nut at the top of the piston rod to the specified torque. Gently release the coil spring compressor and remove it, ensuring that the ends of the spring coils are correctly seated in their seat grooves. Pack grease into the strut upper bearing, keeping it away from rubber components, and then fit the cap.