My Garage

My Account

Cart

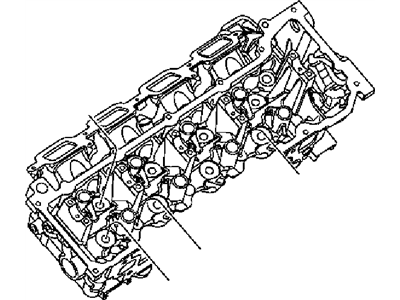

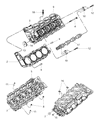

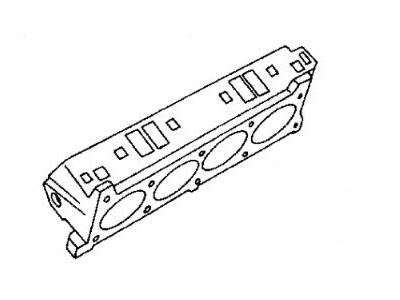

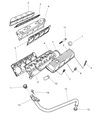

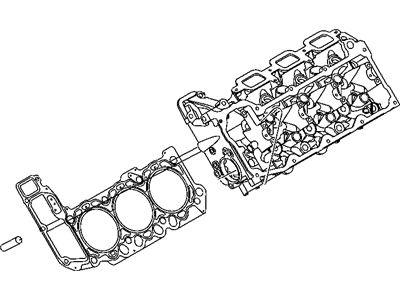

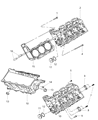

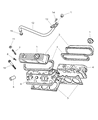

Genuine Dodge Dakota Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Cylinder Heads found

Dodge Dakota Head Cylinder Left See Note

Part Number: 53020987AC$358.47 MSRP: $420.00You Save: $61.53 (15%)

| Page 1 of 3 |Next >

1-20 of 43 Results

Dodge Dakota Cylinder Head

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Dakota Cylinder Head at great affordable prices. Moreover, all genuine Dodge Dakota Cylinder Head come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Dakota Cylinder Head Parts Questions & Experts Answers

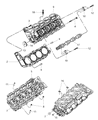

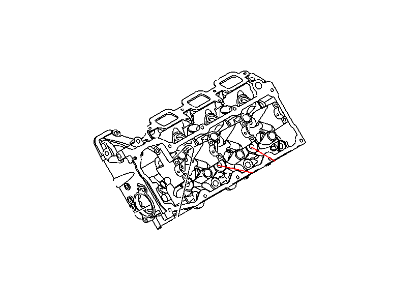

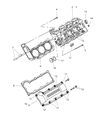

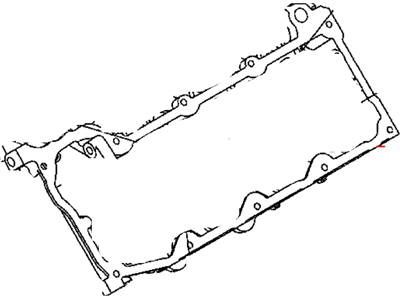

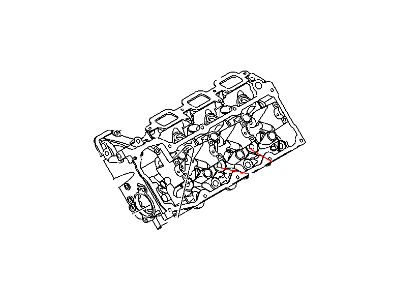

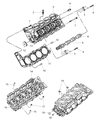

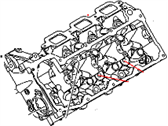

- Q: How to remove and install Cylinder Head in 5.7L V8 engine on Dodge Dakota?A:Before removing the components, reduce the fuel system pressure and then join the cable from the negative terminal of the battery. Empty the cooling system, the Intake Manifold and the exhaust manifolds from the cylinder heads. Then remove the valve covers, then the rocker arm and push rods together with them, so that they can remain hung in the same sequence when reassembling the automobile. Turn the head bolts by 1/4 turn according to the sequence that is the reverse of the tight sequencing until they reach a situation where they can be backed off; where the head bolts are of different lengths, these should be stored in order. Withdraw the heads gently from the engine with the aid of a block of wood and hammer if needed, and place them on other wooden blocks which are to protect the surfaces of the gasket seals. For installation, before fitting the cylinder heads and block clean the mating surface using gasket removal solvents and scraper if necessary. Rub the surfaces with a damp cloth and lacquer thinner or acetone after that, and it is important to cover the lifter valley with the shop rags in order to prevent debris from getting there. Inspect the mating surfaces for flatness and remove nipples and other high spots using emery cloth in case of minor warping; in case of extreme warping, then machining is required. Follow the threads of the head bolt holes by rubbing and scrapes of corrosion on the bolts should be removed using a die. Place the new gaskets accordingly over the dowels in the block and ensure the lettering is rightly positioned. Put the heads in its proper place ensuring it does not shift the gaskets, apply engine oil on the threads of the head bolts then screw them and tighten them by hand before tightening them to the following pattern for torquing. The remaining Steps are the reverse of Remove Steps. Last but not least put in the coolant, put in the oil and the filter, crank the engine, and check the operation and make sure that there is no leakage.

Related Dodge Dakota Parts

Browse by Year

2011 Cylinder Head 2010 Cylinder Head 2009 Cylinder Head 2008 Cylinder Head 2007 Cylinder Head 2006 Cylinder Head 2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head