My Garage

My Account

Cart

Genuine Dodge Grand Caravan Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Pistons found

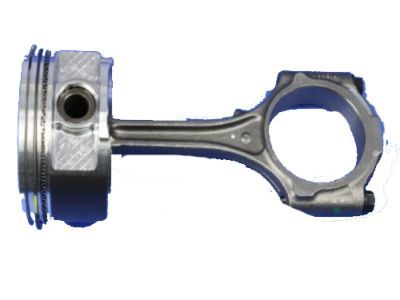

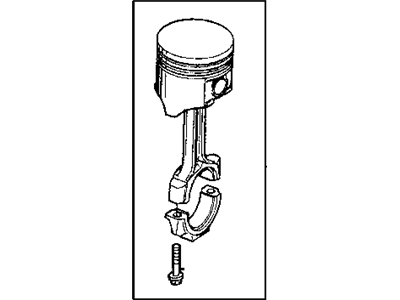

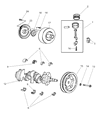

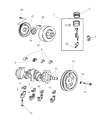

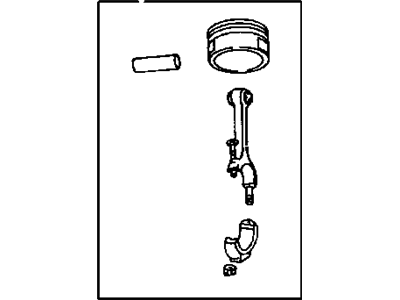

Dodge Grand Caravan Piston V6 W/PIN Std B

Part Number: MD119671$28.51 MSRP: $36.27You Save: $7.76 (22%)

| Page 1 of 2 |Next >

1-20 of 21 Results

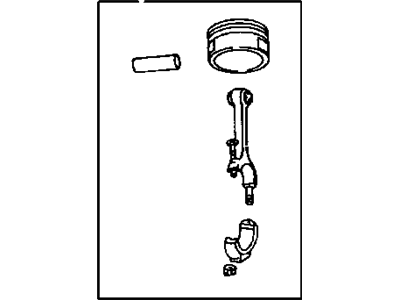

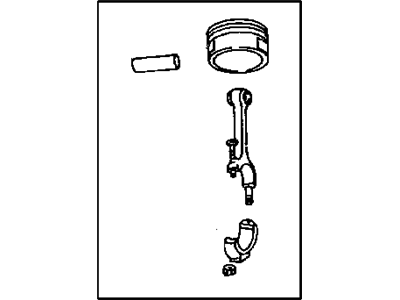

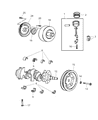

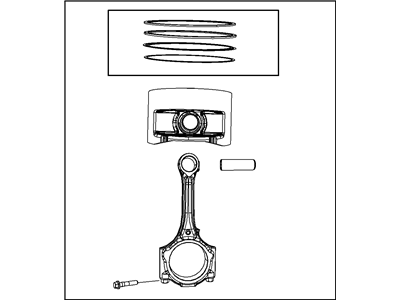

Dodge Grand Caravan Piston

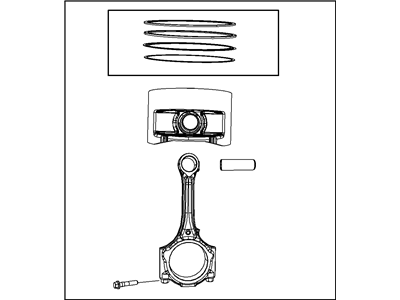

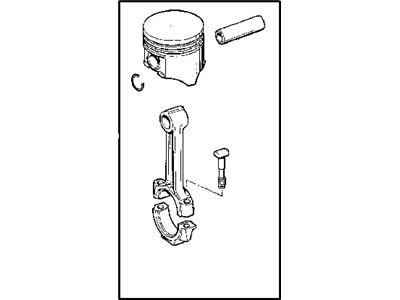

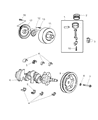

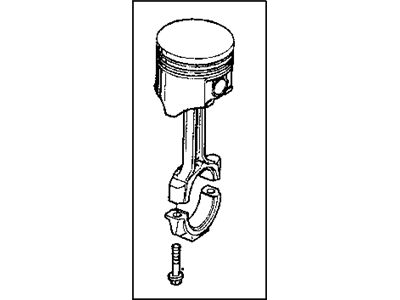

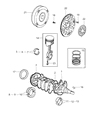

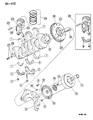

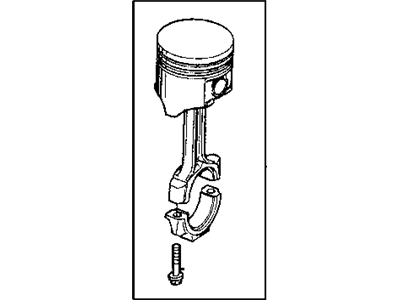

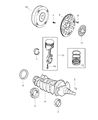

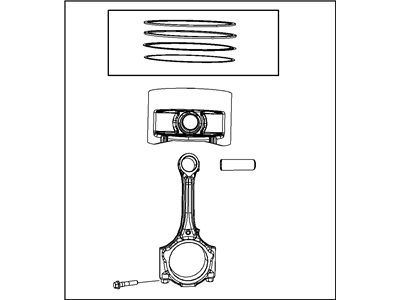

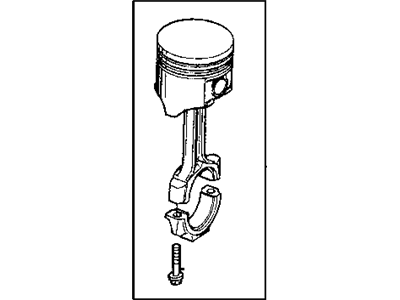

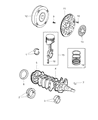

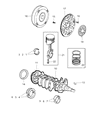

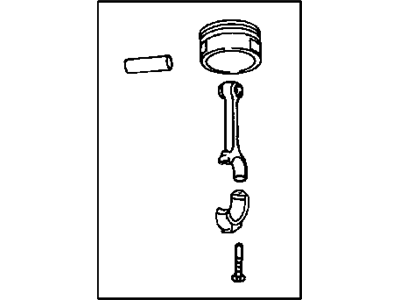

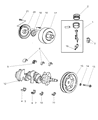

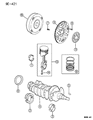

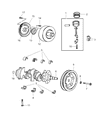

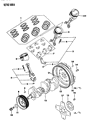

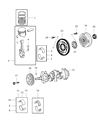

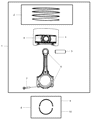

A Dodge Grand Caravan vehicle depends on its Piston as an essential internal combustion engine part applied to convert combustion energy into the power that moves the vehicle. The Piston functions as a mechanism by moving force from pressure buildup of gases toward the crankshaft to deliver maximum engine performance. The production of aluminum alloys provides strength to Pistons that also benefit from lightweight properties in their construction while designers can add cooling cavities and gas-tight Piston rings to their designs. The different Piston kinds applied throughout Grand Caravan versions consist of trunk Pistons for side force support along with crosshead parts built for large diesel engines that improve lubricating abilities and cut down friction. Slipper system parts serve high-speed applications to provide balanced operation and racing Dodge replacement units ensure lightweight strength properties for operating at maximum RPMs. The different Dodge Grand Caravan replacement part types fill distinct performance requirements that boost engine efficiency as well as product life span.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Grand Caravan Piston at great affordable prices. Moreover, all genuine Dodge Grand Caravan Piston come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Grand Caravan Piston Parts Questions & Experts Answers

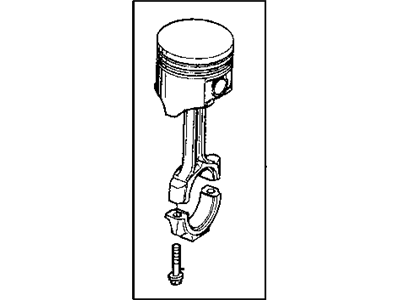

- Q: What steps should be taken before installing the piston and connecting rod assemblies on Dodge Grand Caravan?A:When positioning the piston and connecting rod assemblies make sure that the cylinder walls are free of contaminants, the top land of every cylinder is crowned, and the crank-shaft has been installed. Take off the cap of the number one connecting rod while ensuring that you look at the marks that were made; clean the bearing surfaces of the rod with a fabric . Do not touch the new bearing inserts with fingers as this expose the bearing insert to contaminants. Then, please clean the back side of new upper bearing insert and fit it in the connecting rod such that without hammering in the tab fits in the recess. Again, follow this process with the lower bearing insert in the rod cap where both mating surface should be free of oil and dirt. Align the gables of the piston rings properly, direct a hose over every connecting rod cap bolt, apply clean engine oil onto the piston and the rings, then fit a piston ring compressor such that part of the skirt can be observed. Bore the engine horizontally in such a way that the number one connecting rod journal is facing the bottom and lubricate the walls of the cylinder with the engine oil. Place the piston/connecting rod assembly so that the piston is on the up/even/required stroke, apply a gentle impact so as to seat the piston in the cylinder bore while slipping on the connecting rod to the Crankshaft journal. The final step is measurements of oil clearance on connecting rod bearing using Plastigage and the crushed width has to be compared with the scale. If the clearance is incorrect, be sure that there were no debris during the measurement and inspect the journal diameter. Remove the Plastigage from the bearings with great care, spread a thin layer of oil on the bearing faces and replace the connecting rod and cap which should be tightened three quarters of a turn in sequence. Do the same for other assemblies and wipe the bearing surfaces, make sure the piston is the correct way round, lubricate the cylinder walls and feel for binding by rotating the crank shaft. Last but not the least, check the connecting rod end play as well and make sure it is within standard in case of variation inform an automotive machine shop.