My Garage

My Account

Cart

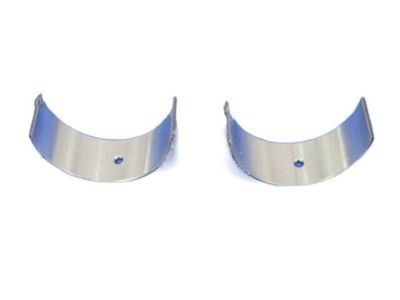

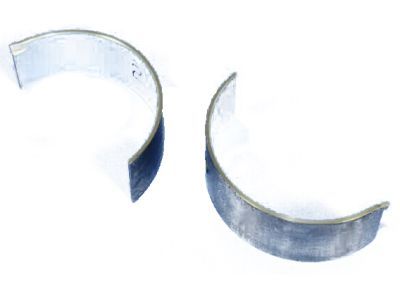

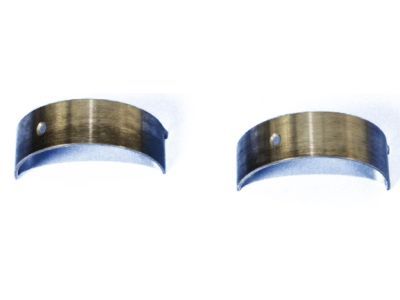

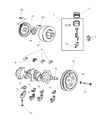

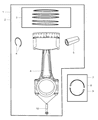

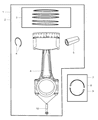

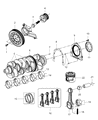

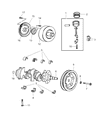

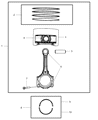

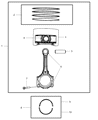

Genuine Dodge Grand Caravan Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Rod Bearings found

Dodge Grand Caravan Connecting Rod Bearing

Part Number: 5184112AF$16.37 MSRP: $23.55You Save: $7.18 (31%)

Dodge Grand Caravan Connecting Rod Bearing

Part Number: 5174612AA$14.51 MSRP: $24.10You Save: $9.59 (40%)

Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 68002286AA$18.70 MSRP: $27.05You Save: $8.35 (31%)

Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 5012056AA$18.70 MSRP: $27.05You Save: $8.35 (31%)

Dodge Grand Caravan Connecting Rod Bearing

Part Number: 5184113AF$3.84 MSRP: $5.65You Save: $1.81 (33%)

Dodge Grand Caravan Connecting Rod Bearing

Part Number: 5184111AF$3.84 MSRP: $5.65You Save: $1.81 (33%)

Dodge Grand Caravan Connecting Rod Bearing

Part Number: 68027463AA$15.67 MSRP: $22.60You Save: $6.93 (31%)

Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 5161294AA$18.70 MSRP: $27.05You Save: $8.35 (31%)

Dodge Grand Caravan Connecting Rod Bearing

Part Number: 5093448AB$16.78 MSRP: $24.10You Save: $7.32 (31%)

Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 68002287AB$10.78 MSRP: $15.50You Save: $4.72 (31%)

Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 68002288AB$8.27 MSRP: $11.85You Save: $3.58 (31%)Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 68002286AB$18.70 MSRP: $27.05You Save: $8.35 (31%)Dodge Grand Caravan Connecting Rod Bearing

Part Number: 68027461AA$16.78 MSRP: $24.05You Save: $7.27 (31%)Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 68002288AA$1.11 MSRP: $2.45You Save: $1.34 (55%)Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 68002287AA$10.78 MSRP: $15.50You Save: $4.72 (31%)Dodge Grand Caravan Connecting Rod Bearing

Part Number: 5012588AA$16.78 MSRP: $24.10You Save: $7.32 (31%)Dodge Grand Caravan Bearing Pkg-Connecting Rod

Part Number: 5012589AA$19.22 MSRP: $27.50You Save: $8.28 (31%)Dodge Grand Caravan Bearing Kit-Connecting Rod

Part Number: 5012590AA$19.22 MSRP: $27.50You Save: $8.28 (31%)Dodge Grand Caravan Bearing Pkg-Connecting Rod

Part Number: 5093449AA$19.22 MSRP: $27.50You Save: $8.28 (31%)

| Page 1 of 2 |Next >

1-20 of 26 Results

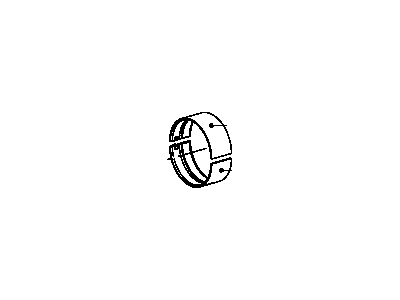

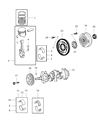

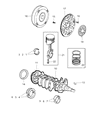

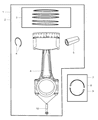

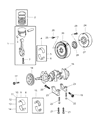

Dodge Grand Caravan Rod Bearing

The Rod Bearing of the Dodge Grand Caravan plays the importance of supporting crank shafts and the connecting rod to rotate in a smooth manner with least resistance. These bearings are normally of plain type which their construction can be either bi-metal or tri-metal type. Bi-metal bearings are lined with aluminum alloy whereas tri-metal bearings consist of a copper bearing alloy and a lead-tin-copper overlay which offers additional strength and durability. Year after year, Dodge Grand Caravan models have incorporated both bi-metal and tri-metal Rod Bearings, while performance models frequently introduced complex materials and coatings in an effort to enhance the film's compression strength. These bearings are designed in such a way that would allow it to have an oil clearance which is very important for both engine efficiency and durability. Misalignment of the Rod Bearings or poor installation may lead to a lot of wear and tear hence affecting the working of the Dodge Grand Caravan's engine.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Grand Caravan Rod Bearing at great affordable prices. Moreover, all genuine Dodge Grand Caravan Rod Bearing come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Grand Caravan Rod Bearing Parts Questions & Experts Answers

- Q: How to inspect Rod Bearing on Dodge Grand Caravan?A:In the course of an overhaul, the main and connecting-rod bearings, on the one hand, should be renewed, while retaining the old ones on the same engines, on the other hand, for examination. Some of these problems may include improper lubrication, dust deposits, overloading of the engine, and cases of corrosion and all these must be attended to before reassembly is done to avoid repetition. When inspecting bearings they have to be taken out of their conventional positions, with regard to fitting on the crankshaft journal, at a clean surface to match any troubles with the bearings. Contaminants can be carried into the engine during assembly, through the filters or as a result of machining and can become lodged in the bearing material and larger particles can cause scoring. To avoid such failures it is necessary always to clean all the parts of the vehicle and often change the oil and filters. Lubrication breakdown may be attributed to heat, loading, leakage and blockage of the passages and such effects are violent where the bearing material is squeezed from its matrix. They also affect bearing durability; for example, loading the engine or short running wears and corrodes the bearings. Further, behaviours such as having bearing surfaces overly tight or entrapping contaminants will yield to inadequate oil supply and failure.

Related Dodge Grand Caravan Parts

Browse by Year

2020 Rod Bearing 2019 Rod Bearing 2018 Rod Bearing 2017 Rod Bearing 2016 Rod Bearing 2015 Rod Bearing 2014 Rod Bearing 2013 Rod Bearing 2012 Rod Bearing 2011 Rod Bearing 2010 Rod Bearing 2009 Rod Bearing 2008 Rod Bearing 2007 Rod Bearing 2006 Rod Bearing 2005 Rod Bearing 2004 Rod Bearing 2003 Rod Bearing 2002 Rod Bearing 2001 Rod Bearing 2000 Rod Bearing 1999 Rod Bearing 1998 Rod Bearing 1997 Rod Bearing 1996 Rod Bearing 1995 Rod Bearing 1994 Rod Bearing 1993 Rod Bearing 1992 Rod Bearing 1991 Rod Bearing 1990 Rod Bearing 1989 Rod Bearing 1988 Rod Bearing 1987 Rod Bearing