My Garage

My Account

Cart

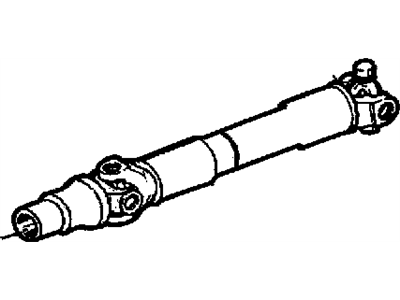

Genuine Ram 1500 Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Universal Joints found

Ram 1500 Universal Joint

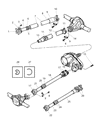

The Universal Joint of Ram 1500 vehicles is one of the important parts of the car - it connects the driveshaft to the transmission assembly and rear axle for proper mobility. For these parts, the good practices for maintenance include frequent greasing and lubrication. It is easy to tell that you have issues with your U Joint on your Ram 1500 by these symptoms: squeaking sound on start up, vibrations as you accelerate and transmission gasket leaks. The remedy is in doing repairs early enough to avoid aggravation of the situation. With differences in angles of rotation and number of axes, the conventional gimbal joint has gradually transformed in its functions serving various necessities of industries in the present analysis on the universal joint.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Ram 1500 Universal Joint at great affordable prices. Moreover, all genuine Ram 1500 Universal Joint come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Ram 1500 Universal Joint Parts Questions & Experts Answers

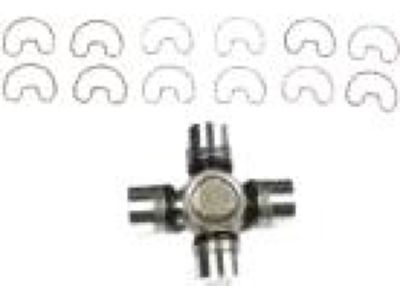

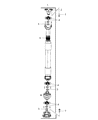

- Q: What are universal joints and how can their wear be identified on Ram 1500?A:Universal joints are mechanical couplings that connect two rotating components that meet at different angles. These joints consist of a yoke on each side connected by a crosspiece, known as a trunnion. Cups at each end of the trunnion contain needle bearings which provide a smooth transfer of the torque load, and snap-rings, either inside or outside of the bearing cups, hold the assembly together. Wear in the needle roller bearings can be identified by vibration in the drive line, noise during acceleration, and in extreme cases of lack of lubrication, metallic squeaking and ultimately grating and shrieking sounds as the bearings disintegrate. To check if the needle bearings are worn, one can try to turn the shaft with one hand while holding the rear axle flange or the front half coupling. Any movement between the driveshaft and the front half couplings, and around the rear half couplings, indicates considerable wear. Another method is to use a pry bar inserted into the gap between the universal joint and the driveshaft or flange. Leaving the vehicle in gear and trying to pry the joint both radially and axially can reveal any looseness. A final test for wear is to attempt to lift the shaft and note any movement between the yokes of the joints. If any of these conditions exist, it is recommended to replace the universal joints with new ones.