My Garage

My Account

Cart

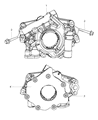

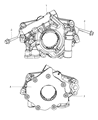

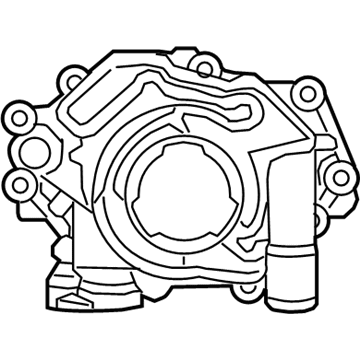

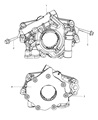

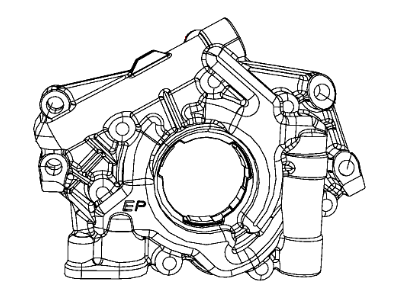

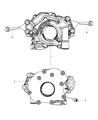

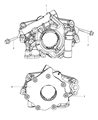

Genuine Chrysler 300 Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Oil Pumps found

| Page 1 of 2 |Next >

1-20 of 26 Results

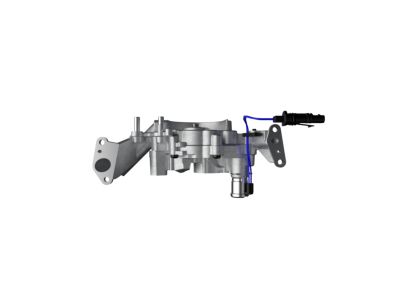

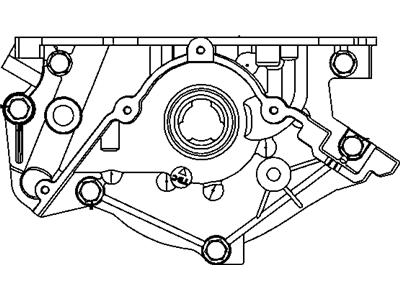

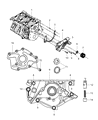

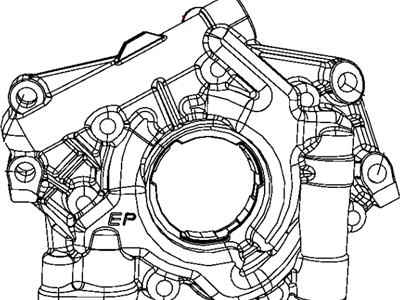

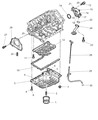

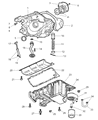

Chrysler 300 Oil Pump

Chrysler 300 automobile carry the Oil Pump which has the function of circulating oil under pressure to maintain and control the operations of the Internal Combustion Engines. It provides lubrication and cooling to such important parts of a car such as bearings and pistons and also serves as a hydraulic fluid for small actuators. The Chrysler 300 dates normally come outfitted with mechanical oil pumps that are driven by either the crankshaft or the camshaft. Gear, trochoid and vane pumps could be utilized in the course of model changes of this car and therefore would be useful in selecting an ideal oil pump for different Chrysler 300 cars over the years. The oiling system works on the basis of pumping oil from the sump, filtering it and then circulating it all over the engine with an appropriate oil pressure of about 10 psi per 1000 RPM. A recommended regimes of the Chrysler 300's Oil Pump include timely changes of the oil and filter since debris hampers the durability and capacity of the Oil Pump.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler 300 Oil Pump at great affordable prices. Moreover, all genuine Chrysler 300 Oil Pump come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler 300 Oil Pump Parts Questions & Experts Answers

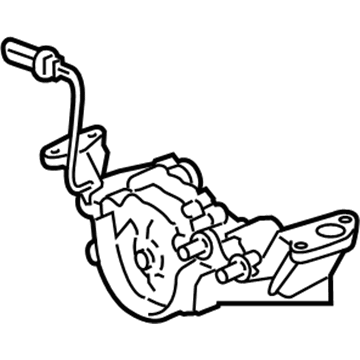

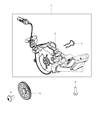

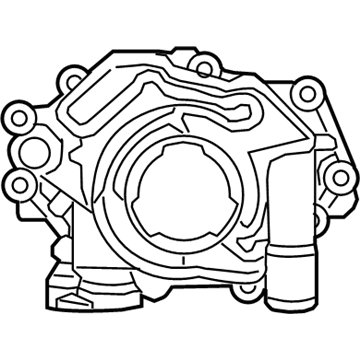

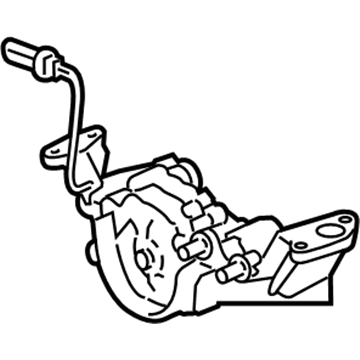

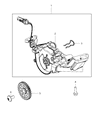

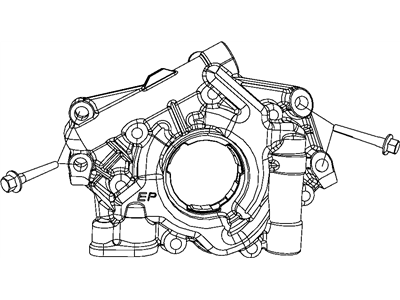

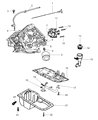

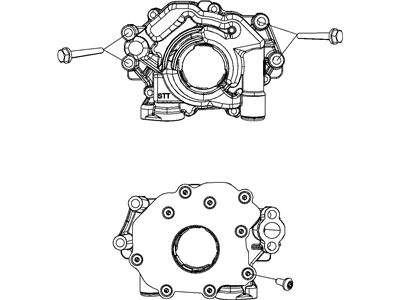

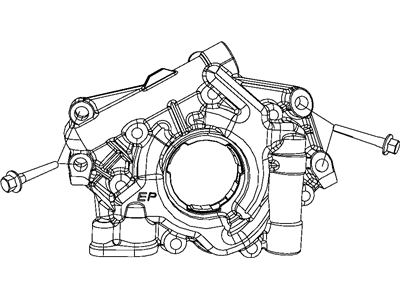

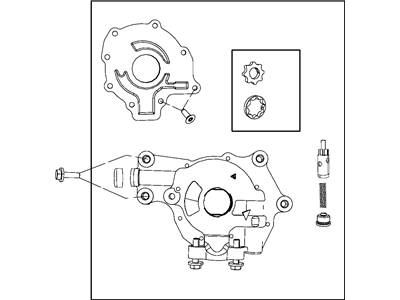

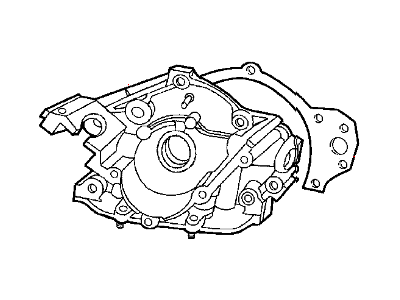

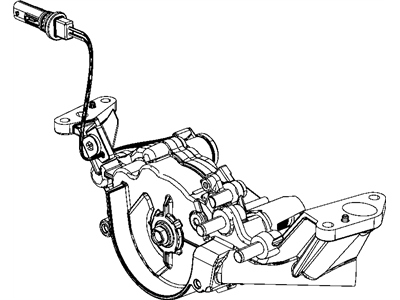

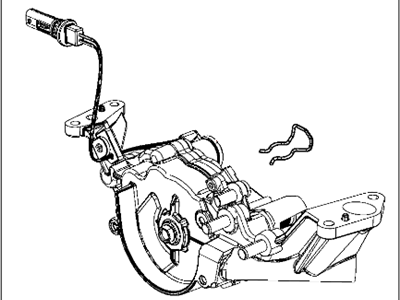

- Q: How to remove and replace the oil pump in 2.7L V6 engine on Chrysler 300?A:The early model replacement oil pumps may suffer from collapsed oil pressure relief valve and spring, leading to oil pressure problems. These pumps do not have a threaded plug but an expansion plug that seals off the oil pressure relief valve and its spring within the pump. Do consult a dealer parts department or other qualified repairer of automobiles for the correct oil pump. First, remove the primary timing chain as well as crankshaft sprocket in order to pull out the oil pump. However, it should be ensured that marks on crankshaft sprocket match those located on housing of the pump before they are disengaged from one another. This would be followed by removal of both: Oil Pan along with an oil pick up tube on it. Then gently take away oil pump housing by prying forward on dowel pins until pump is clear of engine block at front of engine or supported through bolts attaching pump to engine block. Once removed, examine all parts for wear or damage to them; especially certain front coverings which could then be cleaned using solvents for purposes of removing any residual particles contaminating these components. In case sliding surface or even valve spring holding back an this valve are spoilt, these ought to be replaced otherwise intact items left alone. By use of feeler gauge together with micrometer / dial caliper ensure you verify clearance between different parts pertaining to respective oils pumps before crosschecking measurements against specified clearance values; when any clearance becomes too big then whole assembly should be changed out entirely that's if some gap is beyond tolerable extent concerning its constituent components. Ensure there is petroleum jelly packed into the pump first prior its installation whereby all fasteners must be tightened up according torques given while assembling this device once again though this time including such additional elements as valves springs and washers alongside caps just above valves themselves so that latter ones stay in place after reassembling entire unit afterwards making sure each rotor comes into line with one of the crankshafts flats and finally putting these screws back into block or tightening until all tightening torques have been met as outlined by manufacturer instructions. The rest of installation takes place opposite to removal.