My Garage

My Account

Cart

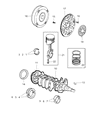

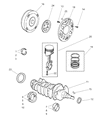

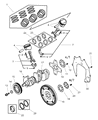

Genuine Chrysler Cirrus Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Rod Bearings found

Chrysler Cirrus Connecting Rod Bearing

Part Number: 5012588AA$16.78 MSRP: $24.10You Save: $7.32 (31%)Chrysler Cirrus Connecting Rod Bearing Package

Part Number: 4728997$15.32 MSRP: $22.20You Save: $6.88 (31%)

Chrysler Cirrus Rod Bearing

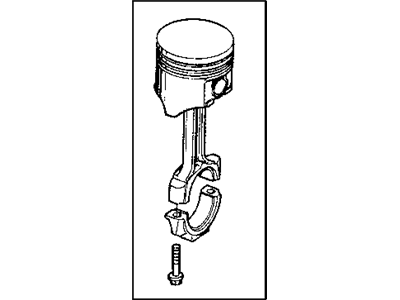

In Chrysler Cirrus vehicles, the Rod Bearing plays an important role because it provides support for the crankshaft and connecting rods in order to rotate effortlessly while at the same time ensures that oil is in right clearance. These bearings are generally 'Plain Bearings' which are bi-metal or tri-metal in structure. Bi-metal bearings have an aluminum alloy layer and are usually administered with silicone to increase their hardness while the tri-metal bearings have a copper alloy layer and a lead-tin-copper overlay to increase the bearings' strength and durability. In Chrysler Cirrus vehicles, there has been the use of several types of Rod Bearings, with those belonging to the performance models tending to make use of tri-metal bearings on account of their better wearing capacities and lubricating capabilities. This performance Rod Bearings may also come with specially developed coatings and or standard eccentricity for enhanced oil clearance and minimum friction when the engine is running at high power conditions. Rod Bearing plays a significant role in the Chrysler Cirrus engine and in order to get a long lasting usage it should be installed and maintained properly.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Rod Bearing at great affordable prices. Moreover, all genuine Chrysler Cirrus Rod Bearing come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Rod Bearing Parts Questions & Experts Answers

- Q: What are the essential steps and considerations during an engine overhaul regarding the replacement and inspection of main and connecting rod bearings on Chrysler Cirrus?A:When overhauling an engine, therefore it is recommended that the main and connecting rod bearings be replaced with new ones and that the old bearings be kept to as they reveal information about the state of the engine. The causes of bearing failure are many, such as lack of oil, dust, overloading of the engine, corrosion among others and all these should be checked before reassembling the engine in order to prevent a repeat incidence. When inspecting bearings they should be taken out from their location and lied aside to allow matching of any defects with the crank shaft journal. They might be trapped in the engine during assembly or through the filter or through the PCV system; some might be machining or reconditioning debris. Some of these foreign particles may be lodged or trapped within the bearing material and can severe scores or gouges if the particle is larger. To avoid such failure, all parts must be cleaned to the best of their ability as well as the oil and filter changes. Inadequate or insufficient lubrication can be caused by reasons such as heat, overloading, leakage of oil or blocked passages, which can lead to severe abrasion, where the bearing material is removed off the backing. Antecedent driving practices also contribute to bearing degradation; for example, full power in slow speeds churns out pressure that compels the oil to expand thus squeezing it, short trips on the other hand encourage corrosion owing to failure of generating adequate heat. Further, there can be wrong fitting of bearings which may outcome into oil deprivation or high point which leads to failures.