My Garage

My Account

Cart

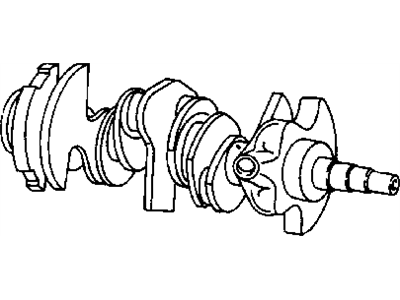

Genuine Chrysler Imperial Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

Chrysler Imperial Crankshaft

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Imperial Crankshaft at great affordable prices. Moreover, all genuine Chrysler Imperial Crankshaft come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Imperial Crankshaft Parts Questions & Experts Answers

- Q: How to remove Crankshaft on Chrysler Imperial?A:The crankshaft can only be removed after the engine has been taken out of the vehicle, assuming that the flywheel or driveplate, crankshaft balancer/vibration damper, timing chain or belt, oil pan, oil pump, counterbalance shafts (if equipped), and piston/connecting rod assemblies have already been detached. Before removal, check the endplay by mounting a dial indicator with the stem aligned with the crankshaft, touching one of the crank throws. Push the crankshaft to the rear and zero the dial indicator, then pry it to the front and check the reading; the distance moved indicates the endplay. If it exceeds the specified value, inspect the crankshaft thrust surfaces for wear, and if no wear is found, new main bearings should resolve the issue. If a dial indicator is unavailable, feeler gauges can be used by prying or pushing the crankshaft to the front and slipping the gauges between the crankshaft and the thrust main bearing to measure clearance. Check the main bearing caps for markings indicating their locations, which should be numbered consecutively from front to rear; if not, mark them with number stamping dies or a center-punch, ensuring to make the punch marks near one of the bolt heads. Main bearing caps typically have a cast-in arrow pointing to the front of the engine. Loosen the main bearing cap bolts gradually until they can be removed by hand, noting any stud bolts for proper reinstallation. Gently tap the caps with a soft-face hammer to separate them from the engine block, using the bolts as levers if necessary, and take care not to drop the bearing inserts. Finally, carefully lift the crankshaft out of the engine, ideally with assistance due to its weight, and with the bearing inserts in place, return the caps to their respective locations on the engine block and tighten the bolts finger tight.