My Garage

My Account

Cart

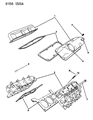

Genuine Chrysler Imperial Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Cylinder Head found

Chrysler Imperial Cylinder Head

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Imperial Cylinder Head at great affordable prices. Moreover, all genuine Chrysler Imperial Cylinder Head come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Imperial Cylinder Head Parts Questions & Experts Answers

- Q: What precautions should be taken before loosening the cylinder head bolts and How to remove and reinstall the cylinder head in 3.3L and 3.8L V6 engine on Chrysler Imperial?A:It is also important to allow the engine to cool before you let go of the cylinder head bolts. Starting with the elimination of the negative terminal of the battery connection, then the intake manifold must be removed. Remove all wires and vacuum hoses that are on the cylinder head(s), additional put labels on all to help with reconnection process. Disconnect the ignition wires and spark plugs with plug wires being labeled preferably. Remove the exhaust manifold bolted to the to be removed cylinder head and unbolt the valve cover(s). Take out the Rocker Arms and the Pushrods. Taking a new head gasket, draw cylinders and the bolt pattern on cardboard with the front of the engine mentioned, and mark the bolt holes. Turn each of the cylinder head mounting bolt about 1/4 turn in an anti-clockwise direction, keep removing the bolts in the sequence opposite to the tightening sequence, and put all the bolts in the cardboard holder for re-use. Loosen the head(s) from the engine, be very gentle because there is no need to pry between the head and the block. If resistance is encountered get a feel for possibly missed head bolts and employ the hammer and wood method to crack the gasket surface and be careful of dowel pins. After removal freese the head on wooden blocks to prevent any damages to the gasket surfaces. For installation it is important that the mating surfaces of each cylinder head and block be free of anycarbon and old gasket material that, using the gasket scraper, they should be cleaned thoroughly with lacquer thinner or acetone. Sprinkle shop rags on top of the litter valley so that no debris goes into the engine and eliminate any that falls into the cylinders. Examine the block and head mating surfaces for wear and tear, take with a file for minor deviation and for significantly distorted, turn to machining. Clean up the threads in the head bolt holes with a tap of the right size to guarantee the right torque figure. Align the new gasket over the dowel pins in the block such that, if the block has any markings, they face the appropriate way. Arranging the head gently on the block so that the gasket does not slip and examined the cylinder head bolts for elongation, and replace them if they are. Torque the bolts to a 45 ft-lbs and in the specified sequence and torque again to 65 ft-lbs. Turn each of them (except one) an additional 90-degrees beyond the initial torque, and do not use the torque wrench on this step, turn the last of them to 25 ft-lbs. Do all of the rest of the steps in reverse order that they came off and do the oil and filter.