My Garage

My Account

Cart

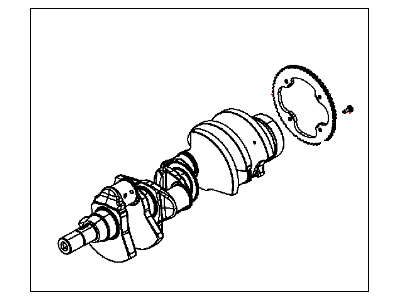

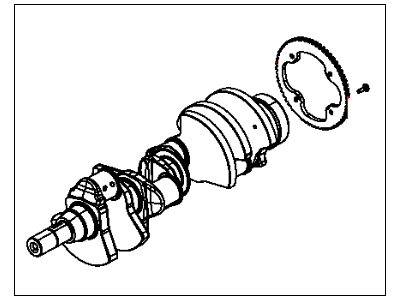

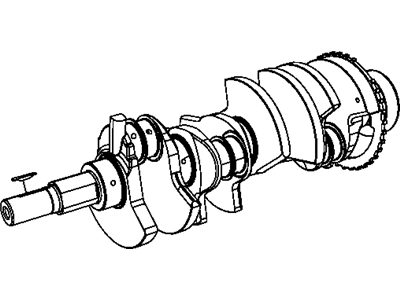

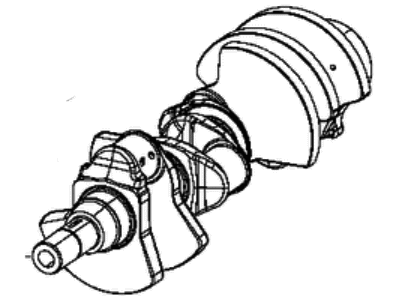

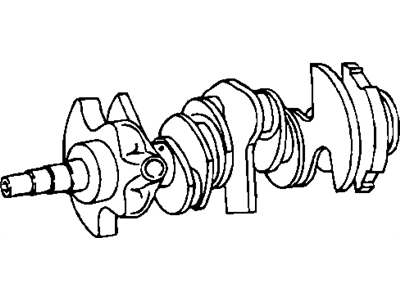

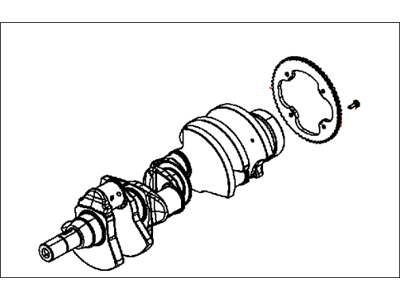

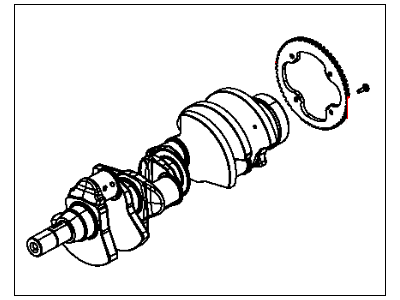

Genuine Dodge Challenger Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Crankshafts found

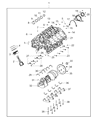

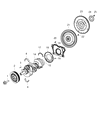

Dodge Challenger CRANKSHAF-Engine

Part Number: 53010906AB$1666.75 MSRP: $2490.00You Save: $823.25 (34%)Dodge Challenger CRANKSHAF-Engine

Part Number: 53010932AB$1677.50 MSRP: $2575.00You Save: $897.50 (35%)Dodge Challenger CRANKSHAF-Engine

Part Number: 68498570AA$1677.50 MSRP: $2575.00You Save: $897.50 (35%)

| Page 1 of 2 |Next >

1-20 of 21 Results

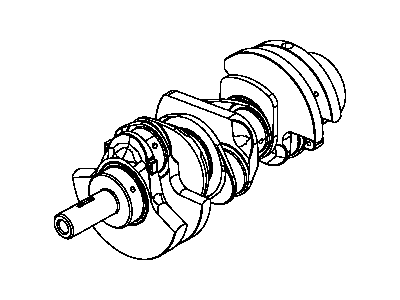

Dodge Challenger Crankshaft

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Challenger Crankshaft at great affordable prices. Moreover, all genuine Dodge Challenger Crankshaft come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

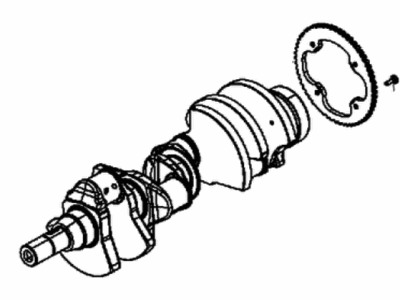

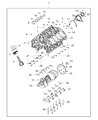

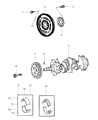

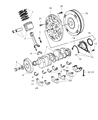

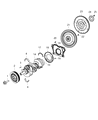

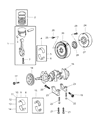

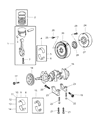

Dodge Challenger Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed and reinstalled after taking the engine out on Dodge Challenger?A:Crankshaft may be removed only after the engine has been pulled out of the car provided that other accessories including the drive plate, crankshaft pulley, timing chain/belt, oil pan, oil pump, oil filter as well as piston/connecting rod assemblies have been withdrawn. Before the crankshaft removal, clean, and place an initial dial reading on the dial indicator touching the crankshaft. Wedge the crankshaft to the rear to obtain zero on the indicator and then wedge the crankshaft to the front to read the difference; ideal measure of end-float is about 0.003- 0.010 of an inch. In case you do not have the dial indicator consider using feeler gauges to measure the clearance. Tighten the main bearing cap bolts gradually, lightly knock the caps with a light hammer gently and then remove the main bearing cap bolts including caps. Take out the crankshaft as it is rather heavy, it is best to do it in pairs, and replace the main bearing cap assembly with the arrow pointing in front. For installation, then it is required to clean the engine block and the crankshaft and examine it before fixing it. Turn the block over; also, remove the main bearing cap assembly and clean the bearing surfaces. Fit new upper and lower main bearing inserts and check that the oil holes are also in position. Measure the main bearing oil clearance with the Plastigage and adjust to the rang of 0.0015 to 0.0023 inch. If clearance is incorrect, check cleanliness to be further confident and in case there is a need, check on the bearings sizes. Once the Plastigage has been removed clean the bearing surfaces and the thrust faces and apply a coat of grease on them then fit the crankshaft and bearing caps and tighten the bolts to the recommended torque. Recheck crankshaft end play and ensure you turn the crankshaft with an appreciable amount of friction. Last but not least, I then fitted the new rear main oil seal.