My Garage

My Account

Cart

Genuine Dodge Challenger Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Oil Pumps found

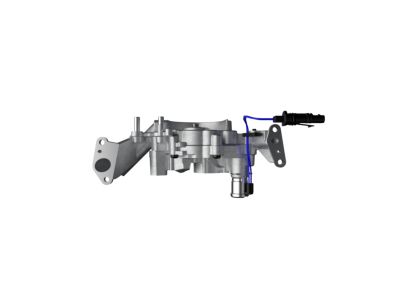

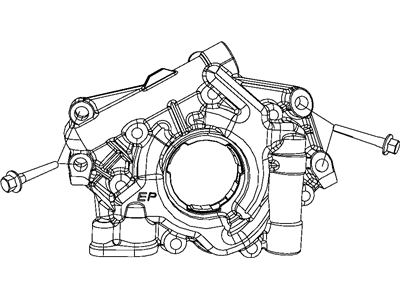

Dodge Challenger Engine Oil Pump

Part Number: 68252670AP$213.75 MSRP: $321.00You Save: $107.25 (34%)

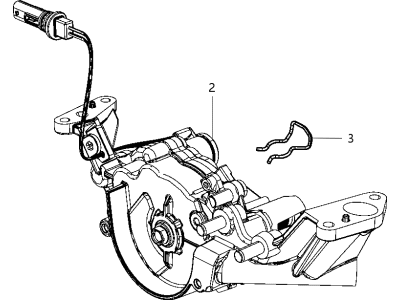

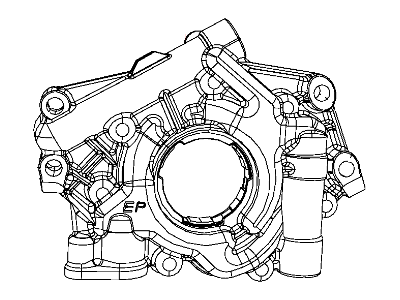

Dodge Challenger Engine Oil Pump

Part Number: 53021622BH$204.75 MSRP: $308.00You Save: $103.25 (34%)

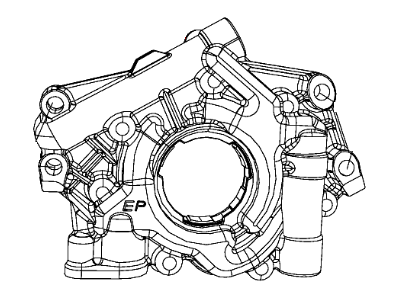

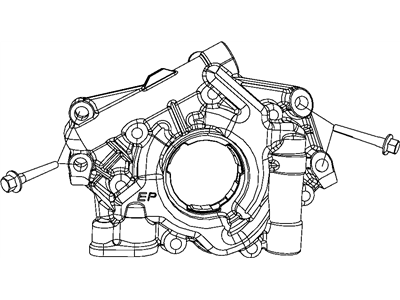

Dodge Challenger Engine Oil Pump

Part Number: 53021622BF$204.75 MSRP: $308.00You Save: $103.25 (34%)

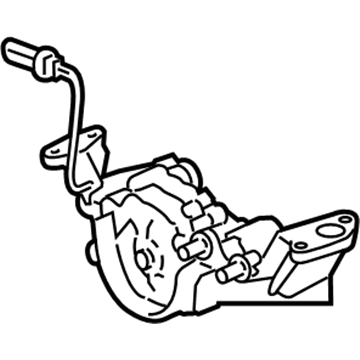

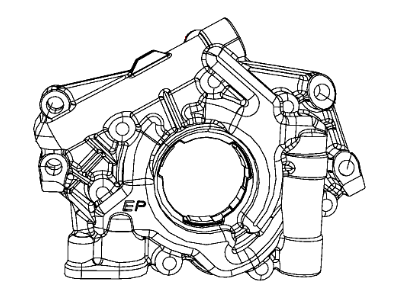

Dodge Challenger Engine Oil Pump

Part Number: 68252670AN$213.75 MSRP: $321.00You Save: $107.25 (34%)

Dodge Challenger Engine Oil Pump

Part Number: 53021622BG$204.75 MSRP: $308.00You Save: $103.25 (34%)

Dodge Challenger Engine Oil Pump

Part Number: 53021622BE$204.75 MSRP: $308.00You Save: $103.25 (34%)

Dodge Challenger Engine Oil Pump

Part Number: 68138644AA$205.30 MSRP: $308.00You Save: $102.70 (34%)

Dodge Challenger Engine Oil Pump

Part Number: 68252670AA$205.30 MSRP: $308.00You Save: $102.70 (34%)

Dodge Challenger Pump-Engine Oil

Part Number: 68252670AB$205.30 MSRP: $308.00You Save: $102.70 (34%)

| Page 1 of 2 |Next >

1-20 of 21 Results

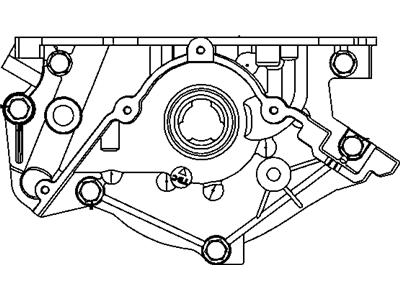

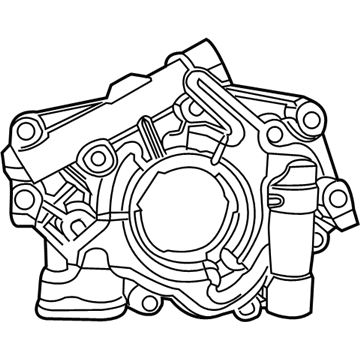

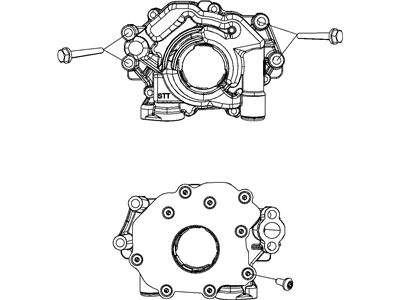

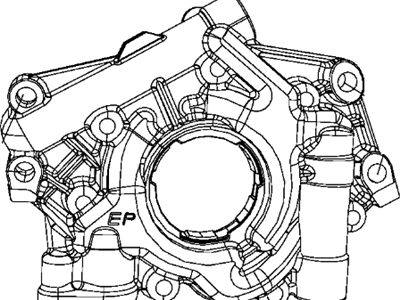

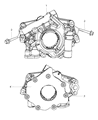

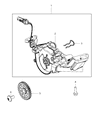

Dodge Challenger Oil Pump

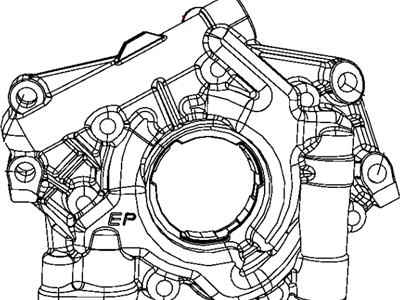

Dodge Challenger automobiles incorporate an Oil Pump that serves a vital function of circulating oil at high pressure thereby supporting the efficiency of the internal combustion engine. It serves as a coolant to important parts such as the bearings, the pistons, the camshaft, and small hydraulic fluid for different actuators. Dodge Challenger usually employs mechanical oil pumps which are driven by the crankshaft or the camshaft, these are very dependable. Several kinds of oil pumps including gear, trochoid, and vane pumps have been used in the Dodge Challenger models in the past several years. Performance versions may use systems like the dry sump systems since at high RPMs, traditional systems may not deliver the required pressure. Certain levels of maintenance such as changing oils and filters help to reduce the clogging of debris with the pump and efficiently the performance of the Dodge Challenger and its engine.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Challenger Oil Pump at great affordable prices. Moreover, all genuine Dodge Challenger Oil Pump come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Challenger Oil Pump Parts Questions & Experts Answers

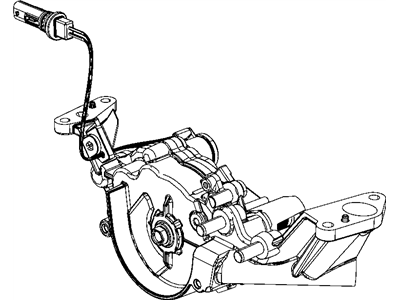

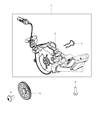

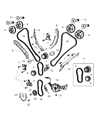

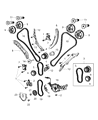

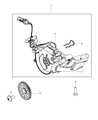

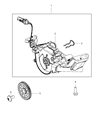

- Q: How to replace and inspect the oil pump experiencing oil pressure problems in 2.7L V6 engine on Dodge Challenger?A:The oil pumps on early model of replacement may have pressure difficulties because of the failure in the pressure relief valve and spring, causing an expansion plug instead of a threaded plug in sealing the said valve and spring within the pump. First of all to start removal reverse the sequence and remove the primary Timing Chain and crankshaft sprocket make sure the mark on the crank shaft sprocket and oil pump housing coincide and do not rotate the crank shaft from this position, which is 60 degree after TDC. Subsequently, take off the oil pan, and then the oil pump pick-up tube, and the oil pump-to-engine block screws from the front of the engine. With some force push the housing in the clockwise direction to remove the dowel pins on the engine block and then pull it out. Worn bearings tend to have a looseness that can be felt during normal disassembly, removal of the screws holding the front cover on the oil pump housing, cleaning all surfaces with solvent and looking for any signs of wear and damage. Screw out the oil pressure regulator cap, washer, spring, and valve and inspect the oil pressure relief valve sliding surface and the valve spring; if the latter is worn out, so is the former and they must be replaced together. Measure the flatness of the cover using a feeler gauge, the outer rotor diameter and thickness and the inner rotor thickness with either a micrometer or a dial caliper and also several clearances. If any of them is oversized, it is advisable to change the whole oil pump assembly. Coat the pump with petroleum jelly to ensure that it is primed, proceed and fit the oil pump, and at last tighten all the screws to the recommended torque. Fit in the oil pressure regulator valve, the spring and washer before tightening the cap of the valve. To install remove the bolts of the pump, fit the flats of the rotor to the similar flats available in the crankshaft, use pump-to-block bolts, and tighten to the recommended torque before following the procedure in the reversal of the above passage.