My Garage

My Account

Cart

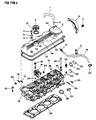

Genuine Dodge Daytona Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Cylinder Heads found

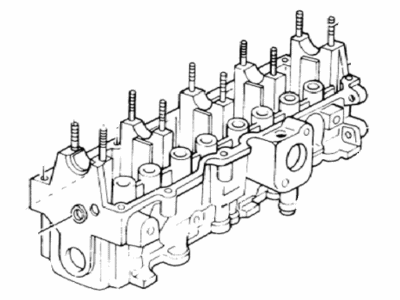

Dodge Daytona Head-Cylinder-Partial

Part Number: 4387614$592.80 MSRP: $867.00You Save: $274.20 (32%)

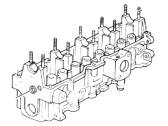

Dodge Daytona Cylinder Head

Inside Dodge Daytona vehicles the Cylinder Head performs as a fundamental engine element which creates air and fuel passages into the engine together with exhaust gas release functions. The engine performance depends on the Cylinder Head since it contains vital valves and spark plugs. The Dodge Daytona models use aluminum Cylinder Heads since they weigh less than cast iron and serve to improve both engine power density and thermal regulation efficiency. The aluminum heads achieve airflow reduction to generate the superior possible horsepower. Manufacturers reinforce the many important head regions because this allows them to shape port areas effectively while factory castings cannot accomplish this. Torque-to-yield (TTY) head bolts combined with the design ensure a reliable seal exists between the head gasket while avoiding coolant leaks and loss of compression. No Dodge Daytona vehicle function properly without a working Cylinder Head because it determines both fuel efficiency and engine performance.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Daytona Cylinder Head at great affordable prices. Moreover, all genuine Dodge Daytona Cylinder Head come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Daytona Cylinder Head Parts Questions & Experts Answers

- Q: What does cylinder head service involve on Dodge Daytona?A:Cylinder head service involves the removal and disassembly of the intake and Exhaust Valves along with their related components. Specialized tools are necessary for disassembly and inspection, and since replacement parts may not always be readily available, it can be more practical and economical for the home mechanic to purchase a replacement head instead of disassembling, inspecting, and reconditioning the original head. New and rebuilt cylinder heads for most engines are typically available at dealerships and auto parts stores. Before removing the valves, label and store them along with their components separately to ensure they can be reinstalled in the same valve guides. Measure the valve spring installed height of each valve and compare it to the specifications; if it exceeds the specified height, the valve seats and faces require attention. Use a spring compressor to compress the valve springs on the first valve, then remove the keepers, and carefully release the compressor to take out the retainer, springs, valve stem seal, spring seat, and valve from the head. If a valve binds in the guide, push it back into the head and deburr the area around the keeper groove. Repeat this process for each remaining valve, ensuring all parts for each valve are kept together for reinstallation. After all valves have been removed and stored, thoroughly clean and inspect the head, completing engine disassembly procedures if a complete overhaul is being performed before starting the cleaning and inspection of the cylinder head.