My Garage

My Account

Cart

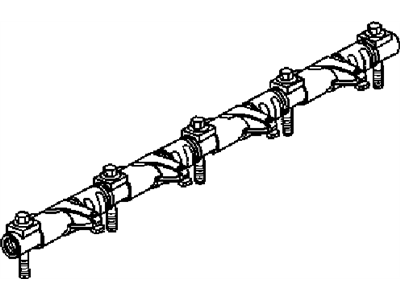

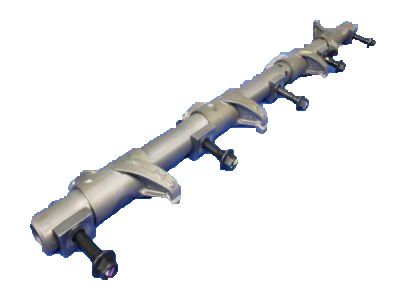

Genuine Dodge Durango Rocker Arm

Engine Rocker Arm- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Rocker Arms found

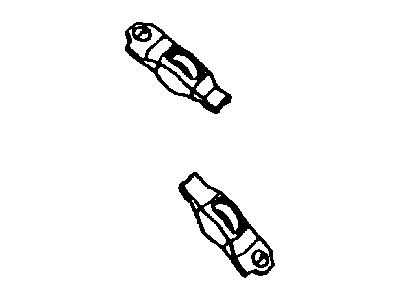

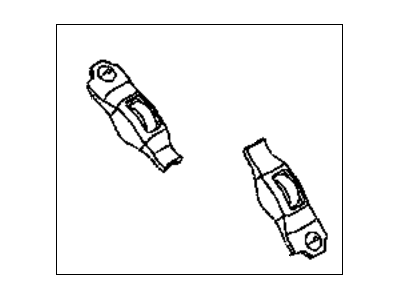

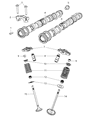

Dodge Durango Engine Intake Rocker Arm

Part Number: 53021552AB$151.88 MSRP: $227.00You Save: $75.12 (34%)

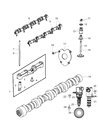

Dodge Durango Engine Intake Rocker Arm

Part Number: 53021552AA$151.88 MSRP: $227.00You Save: $75.12 (34%)

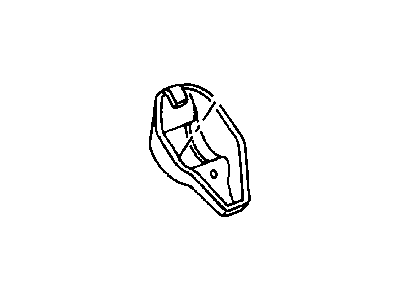

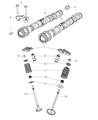

Dodge Durango Engine Intake Rocker Arm

Part Number: 68060343AA$151.88 MSRP: $227.00You Save: $75.12 (34%)

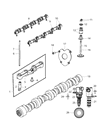

Dodge Durango Rocker Arm

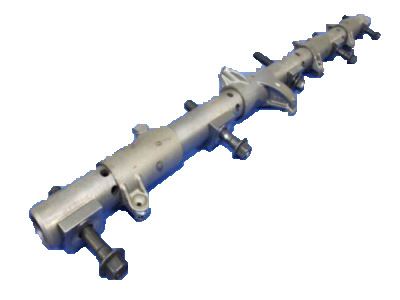

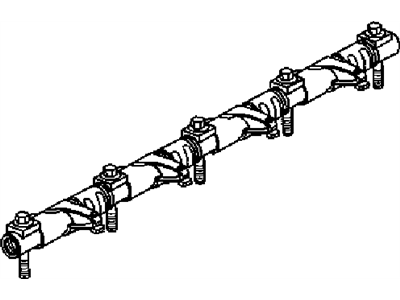

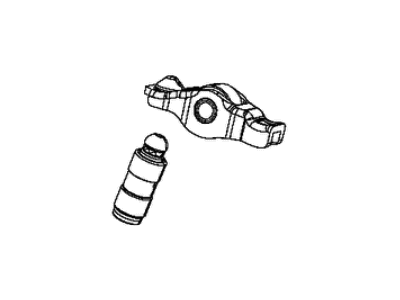

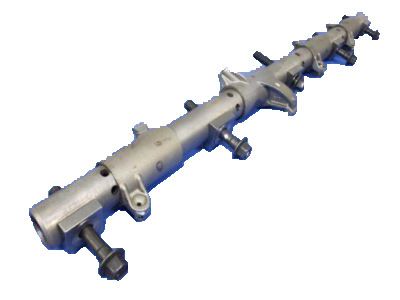

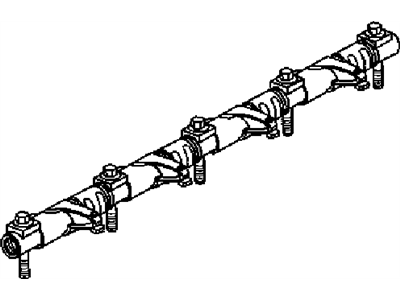

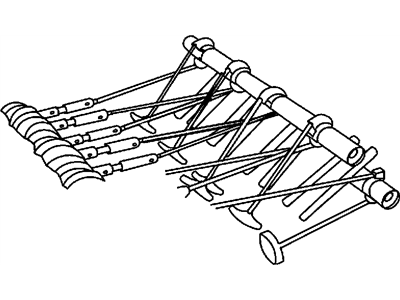

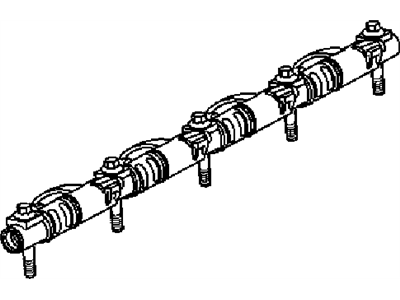

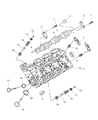

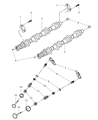

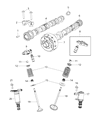

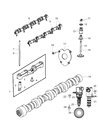

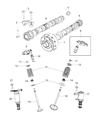

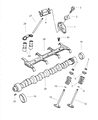

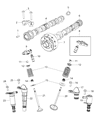

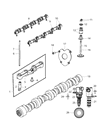

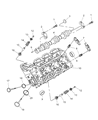

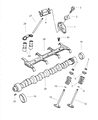

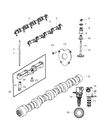

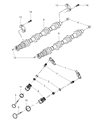

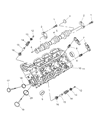

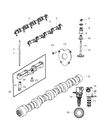

The Rocker Arm that operates in Dodge Durango vehicles exploits a significant position in the valvetrain of the internal combustion engine by converting motion from the pushrod to the intake and exhaust valves. Usually made from stamped steel or aluminium, the Rocker Arm has the responsibility of moving up and down to open the valves in response to the pushrod's vertical movement. For high RPM engines like found in modern cars, aluminum is used because of its light weight nature, although for commercial vehicles and diesel engines and such, cast iron or forged carbon steel is preferred. In the course of its production, Dodge Durango could have normal Rocker Arms, like, Rollers. Roller rockers, which come with needle bearings in order to smoothen the rolling process, are ideal for both the overhead valve engines and the overhead camshaft engines. The rocker ratio that varies from 1.5:1 to 1.8:1 in present day engines can boost camshaft lift therefore the performance. Other example of automobile part, that has been altered for higher stress, RPM or corrosive exposure, can also be seen in the upgraded fulcrum bearings installed in Dodge Durango engines to bear the stress.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Durango Rocker Arm at great affordable prices. Moreover, all genuine Dodge Durango Rocker Arm come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Durango Rocker Arm Parts Questions & Experts Answers

- Q: How do you remove and install Pushrod and rocker arm in 5.7L V8 engine on Dodge Durango?A:To do this you will need to remove the valve covers from the cylinder heads and the bolts that hold the rocker arm shafts in place and these bolts are the center bolts followed by the bolts at the extremity of the rocker arm shafts. After the last nut is fully loosened, carefully lift the rocker shaft assembly off of the cylinder head, being sure note the position betwen the upper intake and lower exhaust rocker arms so that they can be reassembled in their original orientation. Rocker arm positions should be recorded in order to reinstall them in the correct position; each set of components should be replaced and stored as they were found; and the pushrods should be removed and stored in an order to avoid crossing them up. It is important for one to note that exhaust pushrods are a little longer than intake pushrods not interchangeable. If the cylinder heads have been machined to a standard of flatness then it is crucial to 'shorten' the appropriate length pushrods to cover the now shorter distances of the rocker arms to the Camshaft dimensions, unless consulting with a machine shop. For each rocker arm, check if there is wear, cracks, and damage on the surface that comes into contact with pushrods and or valve stems, and the rocker arm shafts and the bores should also be checked to establish if they have worn out and or damaged, a worn out or damaged part must be replaced. There must be free passage into the hole at the pushrod end of each rocker arm; bears checking for crackline and abnormal wear, pushrods can be rolled across a flat surface to check for bend. Coat the lower end of each pushrod with clean engine oil or assembly lube and install these into their original position and ensure that it seals fully into the lifter socket. Coat the valve stems and the upper ends of the pushrods with assembly lube for protection of any mating surfaces during initial start up, then lubricate the rocker shafts, the rocker shaft assembly should have all components located in their original positions before being installed in to the head of the cylinder. Tighten the rocker arm shafts beginning with the centre bolt, in a preset sequence till the appropriate torque is secured so that the pushrods fit tightly in the rocker arms. If bolts when installed appear light before the shaft is seated or if pushrods bind, all the components inside should be examined. Last, put the valve covers back on, crank up the engine, scan for valve train rattles and knock and look for oil leaks at the gaskets.

Related Dodge Durango Parts

Browse by Year

2025 Rocker Arm 2024 Rocker Arm 2023 Rocker Arm 2022 Rocker Arm 2021 Rocker Arm 2020 Rocker Arm 2019 Rocker Arm 2018 Rocker Arm 2017 Rocker Arm 2016 Rocker Arm 2015 Rocker Arm 2014 Rocker Arm 2013 Rocker Arm 2012 Rocker Arm 2011 Rocker Arm 2009 Rocker Arm 2008 Rocker Arm 2007 Rocker Arm 2006 Rocker Arm 2005 Rocker Arm 2004 Rocker Arm 2003 Rocker Arm 2002 Rocker Arm 2001 Rocker Arm 2000 Rocker Arm 1999 Rocker Arm 1998 Rocker Arm