My Garage

My Account

Cart

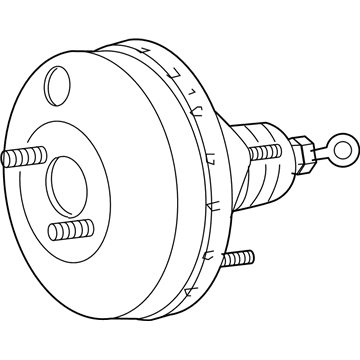

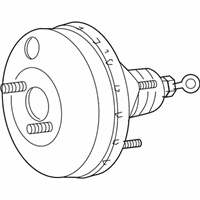

Genuine Dodge Neon Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Brake Boosters found

Dodge Neon Brake Booster

The Brake Booster as a component in Dodge Neon cars plays a critical role in improving the brakes performance where the driver pulls with little effort when using the brakes. It mostly depends on a vacuum linkage, pressure difference between engine vacuum and normal pressure is used to enhance the force applied on the brake pedal. It is less complex and more efficient in braking but this kind of steering system must be used with the engine running. There are chances that Brake Boosters in Dodge Neon models may differ from each other and may consist of vacuum operated boosters or hydraulic boosters. As for vacuum boosters, they are usually quite dependable but may malfunction at times, although hydraulic boosters make use of pressure of fluids. Single or dual diaphragm configurations difference can influence level of power assist, and those with greater diameter offer more assistance. All in all the Brake Booster is an essential component in guaranteeing that the Dodge Neon provides responsive and controllable braking.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Neon Brake Booster at great affordable prices. Moreover, all genuine Dodge Neon Brake Booster come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Neon Brake Booster Parts Questions & Experts Answers

- Q: How do you ensure the power brake booster is functioning properly and How to its remove and install on Dodge Neon?A:Depress the brake pedal several times with the engine off to ensure there is no change in the pedal reserve distance. Start the engine while depressing the pedal; if it goes down slightly, operation is normal. After running the engine for one or two minutes, depress the brake pedal several times slowly; if the pedal goes down farther the first time but gradually rises after the second or third depression, the booster is airtight. While the engine is running, depress the brake pedal and then stop the engine with the pedal still depressed; if there is no change in the pedal reserve travel after holding it for 30 seconds, the booster is airtight. The power brake booster unit requires no special maintenance apart from periodic inspection of the vacuum hoses and the case, and if a problem develops, it must be replaced. To remove the booster, first, remove the battery and the air filter housing, then disconnect the vacuum hose from the power brake booster by pulling straight forward, ensuring to inspect and replace the grommet if necessary. Next, remove the master cylinder, disconnect the power brake pushrod from the top of the brake pedal by prying off the retaining clip, and discard the old clip for safety. Remove the nuts attaching the booster to the firewall, disconnect the brake booster pushrod from the brake pedal arm, and carefully withdraw the power brake booster unit from the firewall and out of the engine compartment. For installation, place the booster into position on the firewall and tighten the retaining nuts, then connect the pushrod to the brake pedal, install the master cylinder, and bleed the brake hydraulic system. The remaining installation steps are the reverse of removal, and it is important to carefully test the operation of the brakes before placing the vehicle in normal operation.