My Garage

My Account

Cart

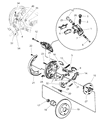

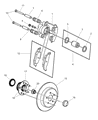

Genuine Dodge Neon Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Brake Discs found

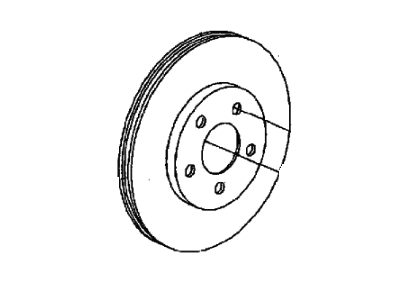

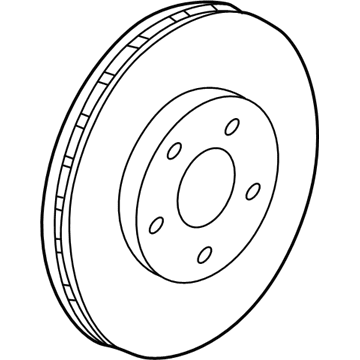

Dodge Neon Brake Disc

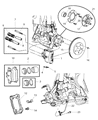

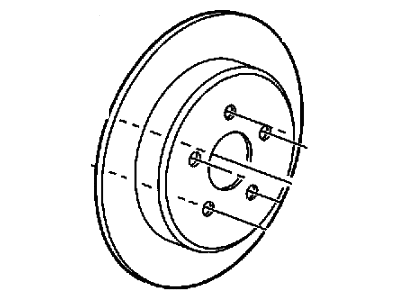

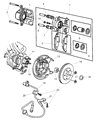

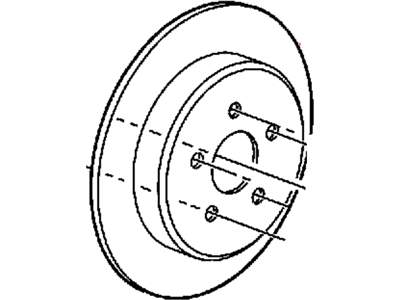

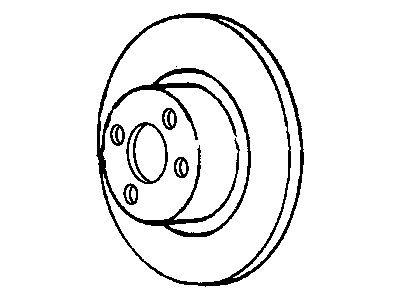

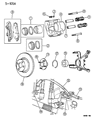

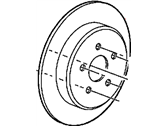

The Brake Disc of Dodge Neon vehicles is one of the parts of the disc brake system which act as the base where brake pad can apply friction to have an efficiency to stop or slow down the vehicle. Attached to the axle or the hub, the Dodge Neon Brake Disc as a component of the wheel assembly just rotates with it, power by hydraulic pressure from the calipers squeezes the pads into contacting the rotor when brake is applied. This design helps in the dissipation of heat in particular in the vented rotors tagged with cooling fins. Dodge Neon vehicles have from time to time made use of both the solid and vented Brake Discs, the solid rotors are commonly used in non-performance oriented cars, and the vented rotors used at the front for cooling purposes. Most rotors are generally made of cast iron while certain areas might employ the use of composites to enhance the efficiency of the rotor. It is imperative that one should inspect and maintain the Dodge Neon Brake Disc from time to time because certain problems like scoring or warping, or excessive runout of the Brake Disc will lead to diminished braking capability and in such cases the Brake Disc must be replaced for safety measure.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Neon Brake Disc at great affordable prices. Moreover, all genuine Dodge Neon Brake Disc come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Neon Brake Disc Parts Questions & Experts Answers

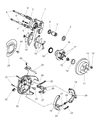

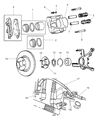

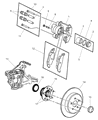

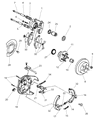

- Q: How do you properly inspect and service brake discs on Dodge Neon?A:Loosen the wheel lug nuts, raise the front or rear of the vehicle, and support it securely on jackstands while applying the parking brake. Remove the front or rear wheels and reinstall the lug nuts with the flat side toward the disc to hold it firmly against the hub. Remove the Brake Caliper and visually inspect the disc surface for score marks and other damage; deep grooves over 0.015-inch require disc removal and refinishing by an automotive machine shop, while light scratches and shallow grooves are normal. To check disc runout, place a dial indicator about 1/2-inch from the outer edge of the disc, set it to zero, and turn the disc, ensuring the reading does not exceed the specified runout limit; if it does, the disc should be refinished. It is recommended to resurface the brake discs to eliminate brake pedal pulsations, and if not resurfaced, deglaze them with sandpaper or emery cloth. The disc must not be machined to a thickness less than the specified minimum thickness, which is cast into the disc and can be checked with a micrometer at several points. For removal, loosen the wheel lug nuts, raise the vehicle, and place it securely on jackstands before removing the wheel. If removing a rear disc, block the front wheels and release the parking brake. Remove the caliper and any retaining clips from the wheel studs, then pull the disc off the hub. If the rear disc won't come off, remove the plug from the parking brake adjusting access hole and turn the adjusting star wheel to retract the Parking Brake Shoes. Installation is the reverse of removal, ensuring the caliper guide pin bolts are tightened to the specified torque.