My Garage

My Account

Cart

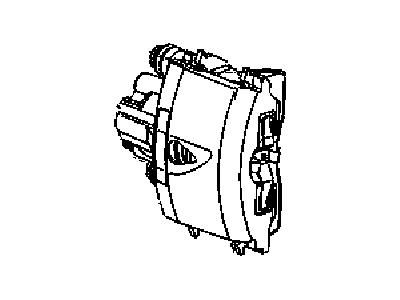

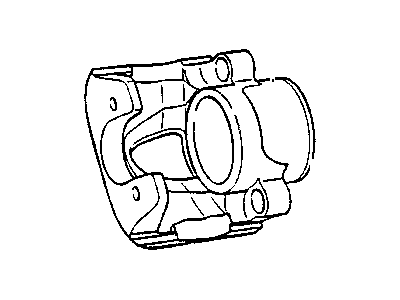

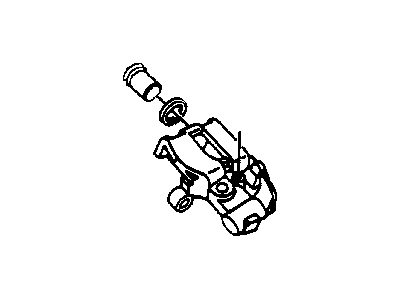

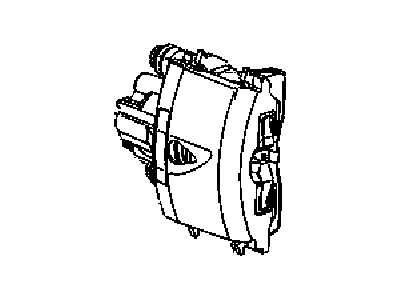

Genuine Dodge Neon Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Brake Calipers found

Dodge Neon Brake Caliper

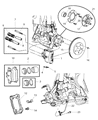

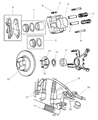

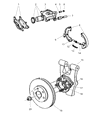

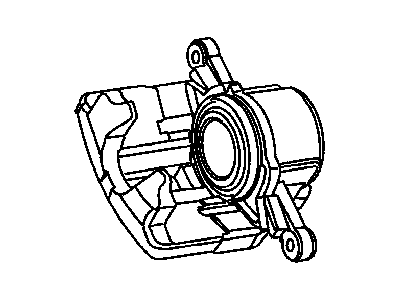

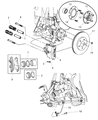

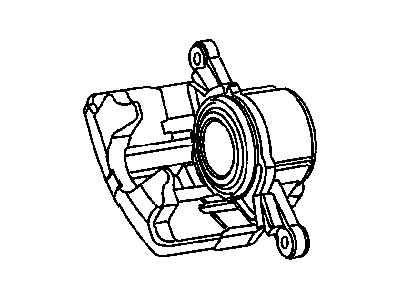

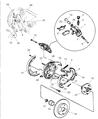

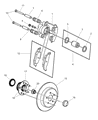

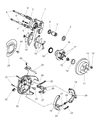

The Brake Caliper in Dodge Neon is a very crucial component when it comes to the braking system because of the fact that it transforms hydraulic pressure from a master cylinder to mechanical pressure. This force is necessary in applying pressure on the brake pads to make contact with the rotors hence slowing down or even bringing the car to a stop. Dodge Neon models utilize two primary types of Brake Calipers: These are the fixed and floating. Fixed calipers use multiple pistons on both sides of the rotor and apply pressure and in a floating calipers use piston on one side and slides to apply pressure and a problem that arises with this kind of type is that it caused uneven wear of the pad. Of course, what you have in your car today, Dodge Neon Brake Calipers vary with time with several variants offered not only as original equipment but also performance brand. Automotive brakes of performance calipers are more reliable and great looking and also it suits for every kind of drive. It is very important to inspect and maintain the Brake Caliper often in the Dodge Neon cars so that the car can perform efficiently and safely.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Neon Brake Caliper at great affordable prices. Moreover, all genuine Dodge Neon Brake Caliper come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Neon Brake Caliper Parts Questions & Experts Answers

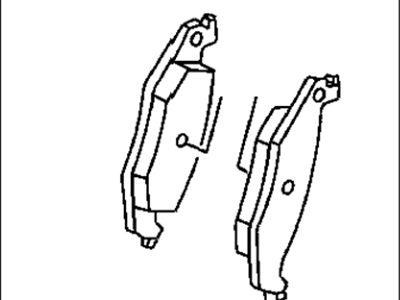

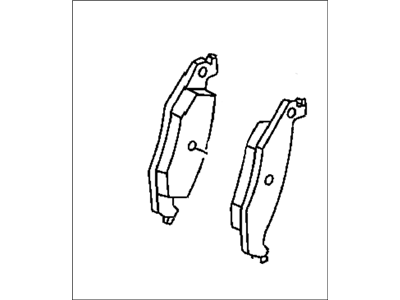

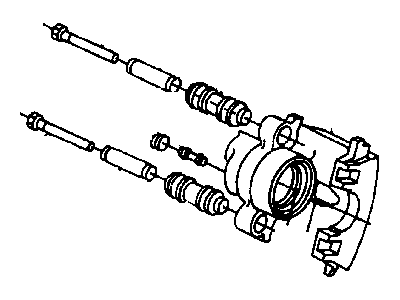

- Q: What steps should be taken when overhauling brake calipers due to fluid leaks, a stuck piston, or a broken bleeder screw on Dodge Neon?A:If it seems that an overhaul is necessary due to leakage, a stuck piston or a broken bleeder screw check all the available possibilities before starting the process. It is relatively easy to order new or factory rebuilt calipers to be used on an exchange basis. When replacing calipers make sure to have rebuild kits available in advance, and make rebuilds or replacements on all calipers in sets of two. To have the caliper, loosen the front wheel lug nuts, then lift the vehicle, and firmly set it on jackstands to have the front or rear wheels. Remove the banjo bolt from the caliper and remove the hose, and the sealing washers have to be discarded while the new one must be used further when tightening the banjo bolt. This should be done to avoid loss and or contamination of the interior of the hose by covering the end with a plastic bag. Remove the previous rubber dust boot from the caliper body and apply brake system cleaner to the surface to remove debris and dust. Check the thickness of the pad and replace when required. During the overhaul, place a piece of shop towels or wood on the caliper to avoid damaging on the piston when removing it using compressed air do not apply too much pressure when operate the air gun. Remove the dust boot in the caliper bore and retract the piston seal with wooden or plastic tool as not to mar them. Take out the bleeder screw and dispose the guide pin bushings and sleeves then, using the brake system cleaner, wipe all the rest parts and blow them dry. Check the piston and caliper bore for surface defects; if there is then replace the caliper. Clean brake fluid should be applied on a new piston seal before placing it in the cylinder groove after the dust boot has been implemented, piston should be fitted into the cylinder. Place the boot in the caliper counterbore, then mount the new guide pin boots and bushings and the bleeder screw should then be fitted. Slide the brake pads into the caliper and then fit the caliper and fasten the guide pin bolts. Join the brake hose employing new sealing washers and then tighten the banjo bolt. Evaculate the brake system, fit in the wheels and the nuts, lift the vehicle to a certain height and over torque the nuts. After the job precipitate the brake pedal several times to align the pads with the disc and then cautiously examine the brake before driving as usual.