My Garage

My Account

Cart

Genuine Dodge Neon Canister Purge Valve

Vapor Canister Purge Valve EVAP- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

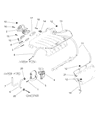

3 Canister Purge Valves found

Dodge Neon SOLENOID-Duty Cycle PURGE

Part Number: 4669475AB$83.87 MSRP: $128.00You Save: $44.13 (35%)

Dodge Neon SOLENOID-Proportional PURGE

Part Number: 4669569$82.07 MSRP: $120.00You Save: $37.93 (32%)

Dodge Neon Canister Purge Valve

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Neon Canister Purge Valve at great affordable prices. Moreover, all genuine Dodge Neon Canister Purge Valve come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Neon Canister Purge Valve Parts Questions & Experts Answers

- Q: What Are the Functions and Replacement Procedures for the Canister Purge Valve and Vapor Canister on Dodge Neon?A:The fuel EVAP system captures fuel vapors and then vents them to join the intake manifold air fuely mixture during operation of the engine. The charcoal canister is mounted at the right front corner of the fuel tank, and when the engine is turned off, fumes move by hoses toward the EVAP canister where it is stored until the next time the vehicle is driven. Vapors pass through a control valve and a flow management valve which also serves as the liquid separation; the flow management valve is a replaceable part whereas the control valve is not, meaning that when the control valve get damaged, the fuel tank has to be replaced. A rollover valve in the fuel tank is located and prevents fuel flow through vapor hoses if it rolls over; it is also non-adjustable. There is an electrically controlled proportional purge solenoid that lets vapor get into the throttle body and this one works when the Powertrain Control Module (PCM) throws open the EVAP canister, but this is not active during cold start and warm up. Other California models from 2000 to 2002 are the LOP, a Leak Detection Pump while in 2003, models made in California have a Natural Vacuum Leak Detection or the NVLD tool. To replace, the proportional purge solenoid must be lifted and the electrical connector removed and hoses labeled before disconnecting them; the solenoid is slid off a clip. In the LOP procedure it is necessary to disconnect the electrical connector, to unbolt the rear stabilizer bar bracket and to remove together with the bracket the pump. The second is the replacement of the EVAP canister in which the vapor hoses are labelled and disconnected, the mounting nuts are removed and the canister is removed from the bracket. For other models not from California, the breather is on top of the EVAP canister, which can be reached only after removing the hose and loosening a bolt to get to it, and making sure that it is in the right position before replacement.