My Garage

My Account

Cart

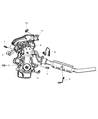

Genuine Dodge Neon Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Oxygen Sensors found

Dodge Neon Lambda Sensor Compatible

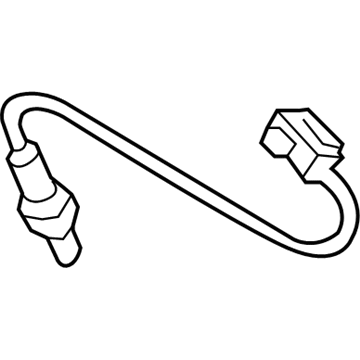

Part Number: 5293036AB$97.23 MSRP: $144.00You Save: $46.77 (33%)

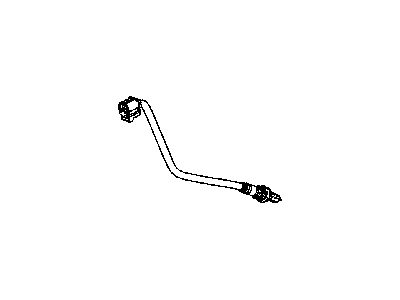

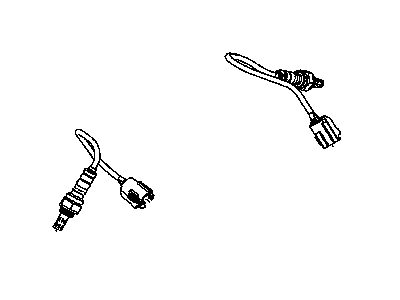

Dodge Neon Oxygen Sensor

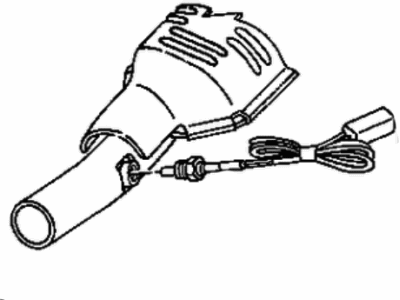

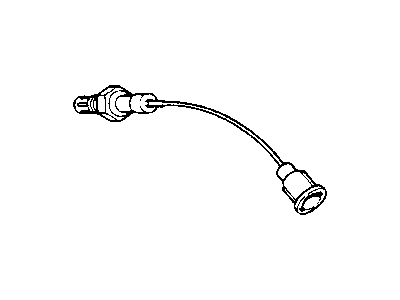

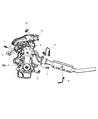

The Oxygen Sensor in the Dodge Neon cars is used to measure the residual oxygen that exists in the exhaust system since this is used to adjust the air/fuel ratio in bid to reduce on emissions. It produces voltage signal proportional to the level of Oxygen hence the engine control computer can vary the fuel injector pulse width. This feedback mechanism makes the engine work in what is called a "closed loop" thus improving catalytic converter effectiveness. A standard Dodge Neon will employ electrical oxygen sensors, in many models employing zirconium dioxide, that can be of the narrow-band or wide-band variety. Narrow-band sensors deliver switching signals rich/lean whereas wide-band sensors offer a variety of mixtures in the air-fuel mode. These sensors may also get worn out due to contamination issues thus increasing the amount of emission and decreasing the fuel economy. The Oxygen Sensor of the vehicle requires constant check-up and service in order to perform at its premier capacity.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Neon Oxygen Sensor at great affordable prices. Moreover, all genuine Dodge Neon Oxygen Sensor come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Neon Oxygen Sensor Parts Questions & Experts Answers

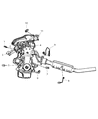

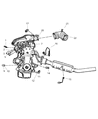

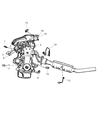

- Q: What special care is essential when servicing an oxygen sensor on Dodge Neon?A:Special caution has to be applied during the servicing of oxygen sensor as it incorporates a permanently installed pigtail and electrical connector, which if damaged or disconnected, will render the sensor useless. Grease, dirt and other contaminants should not get in contact with electrical connector and the louvered end of the sensor, and it is specifically directed that no cleaning solvents should be used on an oxygen sensor or air/fuel ratio sensor. These should not be dropped or handled roughly, also the silicone boot should be correctly fitted so not to melt and to function properly. Oxygen sensors are usually fitted in the exhaust manifold or Catalytic Converter and it becomes very hard to unscrew when cold so getting the car engine running for few minutes is recommended before undertaking the job. First of all, loosen the nut on the negative cable and then safely lift the car on jack stands. The upstream oxygen sensor is mounted on top of the exhaust manifold, to reach this sensor, one has to trace the electrical lead to its connector to disconnect it. With an oxygen sensor socket, unscrew the sensor and with an 18 mm tap clean the threads of the sensor bore. Reinstall the old sensor, if this is done you must coat the threads with anti seize compound, for the new sensors this is not necessary as they are supplied with pre applied compound. Once the upstream sensor has been placed, be sure to retighten it to the recommend torque. The downstream oxygen sensor is installed at different locations depending on the emission package; Federal in the exhaust pipe after the catalytic converter, Low Emission Vehicles on the converter and Ultra Low Emission Vehicles between two converters. By now, the tester is disconnected from the downstream sensor; it is unscrewed using a special socket, and the threads of the sensor bore in the catalytic converter are cleaned. If the old sensor is to be reinstalled then put some anti-seize compound, but not in case of a new sensor. Last is the downstream oxygen sensor, which must be bolted to the factory torque when possible and installation is done in the reverse manner to its removal.