My Garage

My Account

Cart

Genuine Dodge Neon Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Pistons found

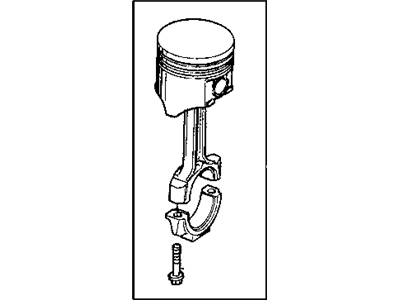

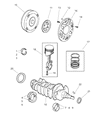

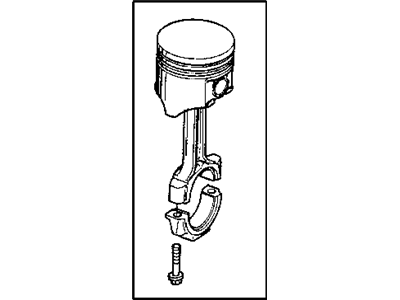

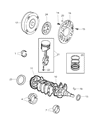

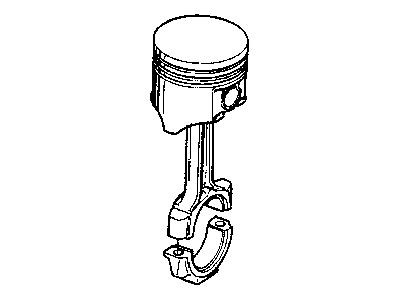

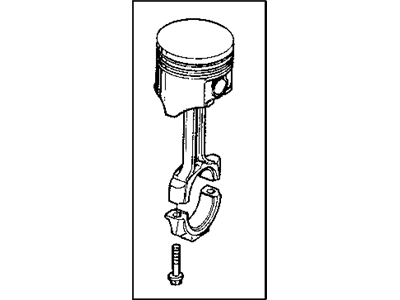

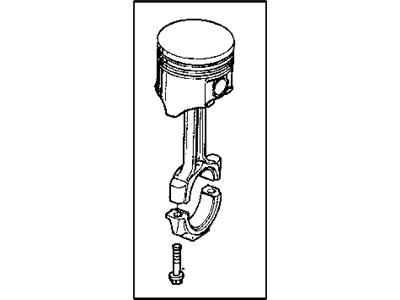

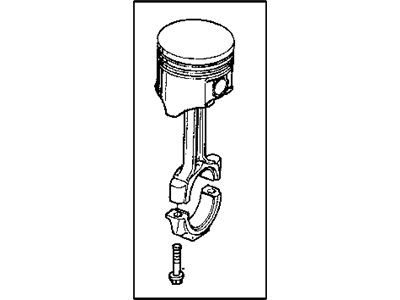

Dodge Neon Piston, Pin, & Rod Assembly, Dohc 16V

Part Number: 4797613$153.35 MSRP: $227.00You Save: $73.65 (33%)

Dodge Neon Piston

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Neon Piston at great affordable prices. Moreover, all genuine Dodge Neon Piston come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Neon Piston Parts Questions & Experts Answers

- Q: What steps must be taken before removing the piston and connecting rod assemblies on Dodge Neon?A:Before pulling out the piston and connecting rod assemblies the cylinder head and oil pan are to be detached. You should dip a fingernail in it, and apply it against the prolongation of the ring travel upward, and any ridges here should be scraped off using a special tool, since if they are left behind, the piston might break. After deburring the vicinity of the ridges, rotate the engine in a manner that a Crankshaft is positioned upwards in order to check perpendicularity and the connecting rod end-float with feeler gauges to reach the aforementioned parameters. Every single connecting rod and cap must be individually recognizable; turn the cap bolts enough that they can be further removed using bare hands. Lift off the chromium plated steel cap and the lead lined bearing insert and extrude the connecting rod/piston assembly through the top of the engine. It is carried out to ensure the caps and inserts are joined back, in order to avoid damaging them during a test. Also make sure that the ring end gaps are correct and that there is correct piston ring side clearance, before fitting new piston rings on the pistons. Put the rings on the pistons beginning with the oil control ring, the second one, and the top ring in the correct position. Scrape and deburr the cylinder walls and the edges of the bores for the piston/connecting rod combination and make sure that the piston is greased and that the ring angles are right. ActivityTwoLook at the connecting rod bearing oil clearance vis check with the help of Plastigage and see whether the Surfaces are clean or not and whether it contains oil or not. If the clearance is not as per specification, cross check the sizes of the bearings and the diameter of the journals. After installation make sure that all parts are clean then wipe the grease on the bearing faces, and then replace the rod caps with new bolts and tighten these bolts to the right torque. Last but not least, turn the crankshaft to tight and looose it again and check for binding, also recheck the connecting rod endplay to ensure that has not altered its position of under 0.0025 inches.