My Garage

My Account

Cart

Genuine Dodge Ramcharger Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Flywheel found

Dodge Ramcharger Flywheel

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Flywheel at great affordable prices. Moreover, all genuine Dodge Ramcharger Flywheel come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Flywheel Parts Questions & Experts Answers

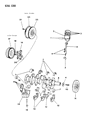

- Q: How to remove and install Flywheel on Dodge Ramcharger?A:These instructions are authoritative only if the engine has been disconnected from the vehicle; if it is left in place, then only the transmission, bell housing, and clutch have to be removed to get at the flywheel. Automatic transmission vehicles use a driveplate instead of the flywheel to be removed by the use of bolts in the Crankshaft. Should the ring gear teeth or driveplate show signs of wear or damage, they should be removed and replaced with new ones, the mounting bolts being tightened to the required torque. First of all, one has to center-punch the flywheel and crankshaft end to ensure that they may be put back only to their initial place. To lock the crankshaft from turning one need to insert a large screwdriver or pry bar between the ring gear teeth and the engine block , but not against the Oil Pan. You may need help to turn the front pulley retaining bolt whilst holding this with a large wrench or socket and a breaker bar. Before taking out the flywheel it is also appropriate to provide support to it to avoid serious harm or destruction. Third, extract the flywheel mounting bolts by the crankshaft flange and pull the flywheel backward in order to disengage it. Installation also appears to occur in the reverse sequence to that which is used for the removal process.