My Garage

My Account

Cart

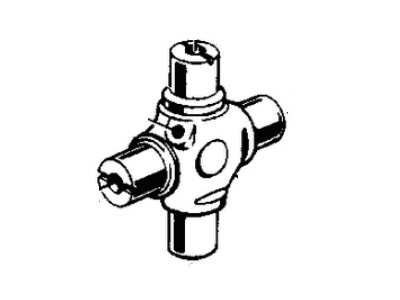

Genuine Dodge Ramcharger Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Universal Joints found

Dodge Ramcharger Universal Joint

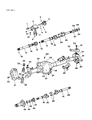

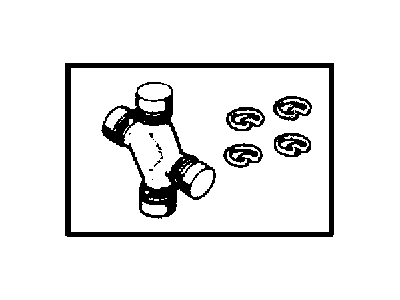

The Universal Joint in Dodge Ramcharger vehicles assists to couple the driveshaft with the differential to require some kind of motion as the suspension altering input reacts towards ground surfaces. This component allows the driveshaft to rotate up and down so that there could be certain change in angle of the drive shaft in relation to the transmission and axle assembly. Usually the Universal Joint is a cross with needle bearings set into hardened steel cups, they are held in position with clips. Through the years, modifications of the Dodge Ramcharger Universal Joints have been noticeable, factory models are already supplied with lubricant while models come with grease zerks for replenishments. Worn Universal Joints can cause visibly low performance, one can experience loud knocks during gear changes and shaking character at velocities, thus, they require undertaking of inspection for replacement. It therefore can be clearly seen that knowledge of the function and care of the Universal Joint is critical in the long-term durability and efficiency of the Dodge Ramcharger vehicles.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Universal Joint at great affordable prices. Moreover, all genuine Dodge Ramcharger Universal Joint come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Universal Joint Parts Questions & Experts Answers

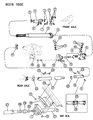

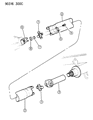

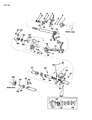

- Q: How do you service conventional universal joints on Dodge Ramcharger?A:To service conventional universal joints, first, mark the joint yokes in relation to each other after removing the driveshaft. Remove the snap-rings from the bearing cups and use two sockets of different sizes to push the bearings out of the yokes, mounting the joint in a vise for this process. Mark the trunnion before removing the remaining bearings and disassemble the universal joint while keeping all components marked for proper reassembly. Clean the driveshaft and components with solvent, inspecting for cracks and damage, and check the trunnion journals and sleeve yoke splines for wear. Replace all needle bearings, cups, washers, snap-rings, and dust seals with new ones during reassembly, packing grease into the trunnion ends and applying grease to the dust seal lips. Carefully install the bearings and trunnion in the yoke, ensuring not to damage the bearing cups, and press the bearing cups into place, followed by installing new snap-rings. For constant velocity joints, mark all yokes before disassembly, disengage the flange yoke and trunnion from the centering ball, and clean and inspect all components for wear, replacing any damaged parts. Lubricate the parts with grease from the repair kit, insert them into the ball seat cavity in the correct order, and attach the flange yoke to the centering ball, ensuring proper alignment before installing the trunnion caps.