My Garage

My Account

Cart

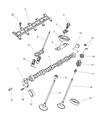

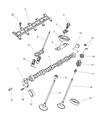

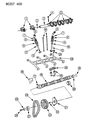

Genuine Dodge Ramcharger Valve Stem Seal

Engine Valve Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Valve Stem Seals found

Dodge Ramcharger Seal-Valve Guide Exhaust

Part Number: 53005772$2.99 MSRP: $8.60You Save: $5.61 (66%)

Dodge Ramcharger Valve Stem Seal

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Valve Stem Seal at great affordable prices. Moreover, all genuine Dodge Ramcharger Valve Stem Seal come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Valve Stem Seal Parts Questions & Experts Answers

- Q: Can broken valve springs and defective valve stem seals be replaced without removing the cylinder head on Dodge Ramcharger?A:Damage to the valve springs and valve stem seals can be repaired with these components while still in place, at most, it will require only two special tools and a source of compressed air and will not necessitate the removal of the cylinder head. Start with the Rocker Arm covers and spark plugs next turning the crankshaft in a way that the number one piston reaches the top dead center but in the compression stroke. Take out the rocker arms and the shaft, and fit a dummy one in place of the real one. Screw an adapter into the spark plug hole and attach an air hose used to connect to a can of compressed air such that the valves are kept open by pressure from the compressed air. With leakage, turn the crankshaft in the anti-clockwise direction until you feel a slight force. To avoid dropping the parts into the engine, insert shop rags into the holes of cylinder head and to compress the spring you use the valve spring compressor then, use the small needle-nose plier or magnet to remove the keepers. This component should be installed with care for different length springs for intake and exhaust valves, since, if wrongly installed, the engine can be completely ruined. Depending on whether you have a stamped or rolled valve, unscrew/ pull out the valve spring and retainer or rotator; the old vale stem seal will also have to be taken out. Tie the top of the valve stem with a rubber band or a tape so that the valve stem does not drop inside the combustion chamber, and then reduce the air pressure. Check up the condition of the valve stem by moving it gently in its guide. Applying pressure to the other side of the valve to make it remain closed (ch 8, p 169), then unwind the tape or rubber band. For exhaust valves fit the cup shield to the valve stem; for intake valves place a new valve Stem Seal on the valve guide so that it is below but not pushed down over the valve guide. To set the spring and retainer or rotator set the assembly up by compressing it just enough to let the keepers into position and make certain that they are correctly seated. Remove the air hose and the spark plug adapter from the spark plug hole if any, or remove the rope used. Perform the same on the other cylinders and fire the cylinder in firing order sequence, using spare rope and tightening pressure till each piston comes at TDC on its compression stroke before applying air pressure or putting in the rope. Last of all, replace the rocker arms and shafts, the rocker arm covers, start the engine and use the dipstick to look for oil leakage and for any queer noises coming out from the vicinity of the rocker arm cover.