My Garage

My Account

Cart

Genuine Dodge Ramcharger Wheel Seal

Wheel Axle Seal- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Wheel Seals found

Dodge Ramcharger Wheel Seal

The Wheel Seal also known as dust deflector is essential tool used in Dodge Ramcharger cars to protect the wheel bearing and hub from damaging forces such as dirt, debris and rocks. Due to accurate protection of grease or lubricant leakage, the Wheel Seal guarantees adequate lubrication of the bearing system so as to avert the chances of overheating and becoming brittle. Dodge Ramcharger models have since used many Wu types of Wheel Seals at one period or another such as the front and rear inner and outer seals. You will come across some of the finest manufacturers including Motorcraft, Beck Arnley and Timken to mention but a few, with such brands you are assured of quality and proper fitting. Therefore, it is helpful for the inspection of Wheel Seal as well as the condition of the Dodge Ramcharger to check for leaks or cracks regularly in order to ensure the performance of the car.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Ramcharger Wheel Seal at great affordable prices. Moreover, all genuine Dodge Ramcharger Wheel Seal come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Ramcharger Wheel Seal Parts Questions & Experts Answers

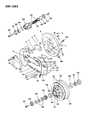

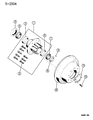

- Q: What are the steps involved in replacing axleshaft oil seals,Wheel Bearing and axleshaft on Dodge Ramcharger?A:Two axleshaft oil seals are utilized on this type of axle, consisting of an inner and an outer seal, with oil seepage at the outer seal typically indicating inner seal failure. Begin by raising the rear of the vehicle and supporting it on jackstands, then remove the wheel and brake drum. Access the axleshaft end flange to unscrew the retainer nuts, and use a slide hammer to withdraw the axleshaft while removing the brake assembly and gaskets. A special tool is required to extract the inner oil seal from the axle housing. Clean the axle housing seal bore and drive in a new seal using a piece of pipe or a large socket and a hammer. If dismantling the axleshaft, cut grooves across the bearing collar with a sharp chisel for removal, avoiding heat to prevent damaging the axleshaft temper. Remove the bearing collar retainer by cutting off the lower edge with a chisel, grind off a section of the bearing inner track flange, and use pliers to remove the bearing rollers. Pull down the roller cage and cut it out, then remove the roller bearing outer track. Protect the seal surface with tape before withdrawing the bearing inner track with a puller, and take out the axleshaft outer seal from the retainer plate. Begin reassembly by installing the retainer plate with a new seal on the axleshaft, press wheel bearing grease into the bearing roller, and install the new bearing outer track, bearing, and collar using a puller. Place a new rubber-coated steel gasket over the axle housing flange studs, followed by the brake assembly, and apply grease to the outer diameter of the bearing outer track to prevent corrosion. Install a foam gasket over the axle housing flange studs, then carefully slide the axleshaft assembly into the housing until the splines engage in the differential side gears, tapping it with a soft-faced hammer until fully seated. Install the retainer nuts, tightening the lower one first, and back off the threaded adjuster before installing the right-hand axleshaft. If any axleshafts have been removed or new components installed, adjust the axleshaft end play with both rear wheels off the ground by turning the axleshaft adjuster ring on the right-hand axleshaft until all end play disappears, then turn the adjuster four notches counterclockwise for the correct end play, ideally between 0.008 and 0.018 inches, using a dial gauge for accuracy. Once the end play is correct, remove one support plate retainer nut and install the adjuster lock, ensuring the tab engages with the notch in the adjuster. Finally, install the brake drums and wheels, and lower the vehicle to the ground.