My Garage

My Account

Cart

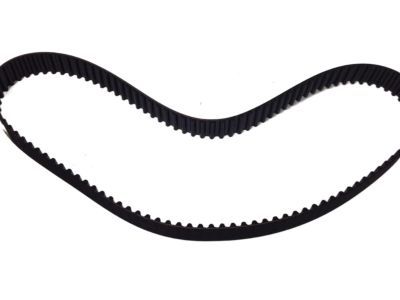

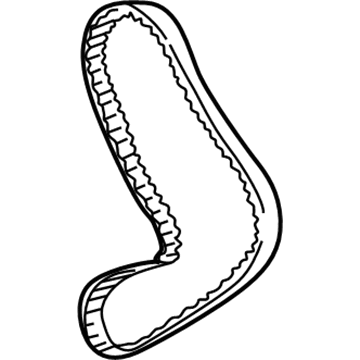

Genuine Chrysler Cirrus Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Timing Belts found

Chrysler Cirrus Timing Belt

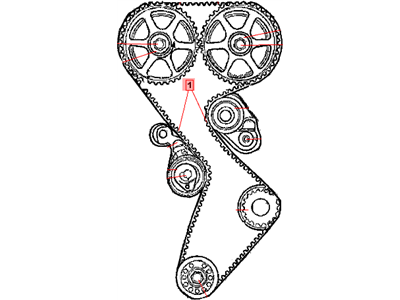

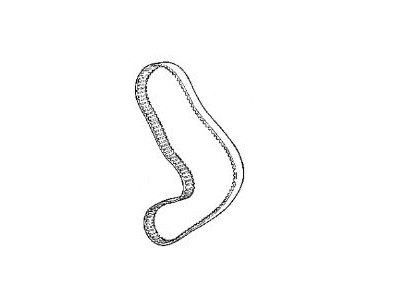

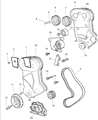

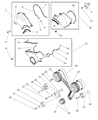

Since the Chrysler Cirrus cars Glen found that the Timing Belt is used to coordinate the operation of the crankshaft and the camshaft, there is proper opening and closing of the engine valves. This synchronization is very important to the performance of the engine especially in relation to the piston movement and the opening and closing of the valves. The Timing Belt: usually rubber manufactured and fortified with fibers costumes this part of the vehicle since it is cheaper to manufacture than the older gear system, it produces lesser noise and experiences less friction. There are many styles of Chrysler Cirrus Timing Belts have been used throughout the years: Improvements have had curved teeth that are resonant and made the belt stronger in most models. The Timing Belt needs to be inspected often and replaced when necessary because if not done, it can result to extensive engine damage particularly if the engine is an interference engine. Further, when there is a need for the Timing Belt replacement it is recommended that other components such as automatic tensioners and idler pulleys should also be replaced to enhance the performance of the engine.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Timing Belt at great affordable prices. Moreover, all genuine Chrysler Cirrus Timing Belt come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Timing Belt Parts Questions & Experts Answers

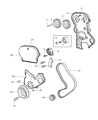

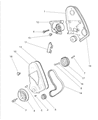

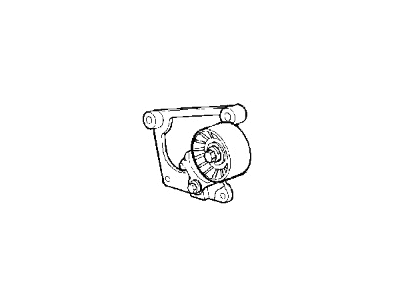

- Q: What precautions should be taken when replacing a timing belt to avoid engine damage in four cylinder engine on Chrysler Cirrus?A:If the timing belt breaks while the engine is still running, valves can be damaged; an engine compression test is thus required after the belt has been fixed. The crankshaft and camshaft(s) should not be turned after the timing belt has been removed to prevent the damage to the valves. Start with the number one piston being set at the Top Dead Centre, then remove the negative battery terminal, and finally the drivebelts. Insert a large screwdriver or bar to hold the crankshaft damper pulley stationary, then, unscrew the large bolt in the center of the pulley. Replace pulley with 3-jaw puller with the right insert to safeguard the crankshaft bolt thread. Next the crankshaft pulley is removed and the crankshaft bolt is then replaced with one that has a spacer. Take off the right engine mount as well as the mounting bracket, while being keen to support the engine. Pull off the timing belt outer cover(s) and you should check the position of the camshaft sprockets and the crankshaft one which should be aligned before you remove the timing belt. Determine which of the timing belt tensioner is hydraulic or mechanical and continue with removal process. Gently remove the timing belt over the sprockets and if it's being re-used then ensure it is stored well. Check condition of crankshaft front oil seal, water pump, tensioner pulleys, timing belt; replace if worn. For installation, also ensure that the camshaft sprocket shows the appropriate timing marks before you position the crankshaft timing belt sprocket in the right position. Place the timing belt over the required elements so that no slack remains; to do this, turn the crankshaft clockwise and counter-clockwise using the tools. For those engines with the mechanical tensioner, it is advised to pull the retaining pin and rotate the crankshaft clockwise and there is some kind of stiffness, then it is paramount that there is contact between the valve and the piston. In hydraulic tensioners, the piston should be preloaded before mounting and applying tension to the pulley of the tensioner. Once aligned timing marks are correctly positioned, inspect the belt tension and then accomplish the procedure by the tightening of crankshaft pulley bolt and road test of the car.