My Garage

My Account

Cart

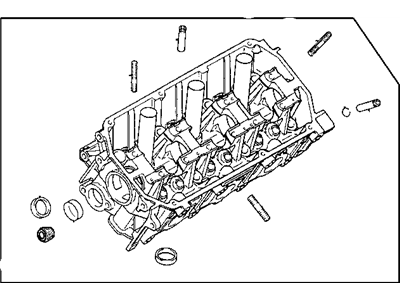

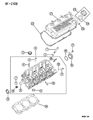

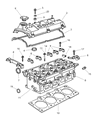

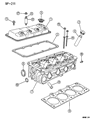

Genuine Chrysler Cirrus Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Cylinder Heads found

Chrysler Cirrus Cylinder Head

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler Cirrus Cylinder Head at great affordable prices. Moreover, all genuine Chrysler Cirrus Cylinder Head come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler Cirrus Cylinder Head Parts Questions & Experts Answers

- Q: What are the steps involved in disassembling and inspecting a cylinder head on Chrysler Cirrus?A:Cylinder heads are new and rebuilt and are often available for order for almost every make and model of engine at dealerships and auto parts stores. Since only specialized tools are required for the removal and inspection of the cylinder head together with potential replacement heads may not be easily acquired, it may very well be more convenient and cost effective for the home mechanic to acquire a new head and bolt it on than to remove, inspect and re-condition the one that came with his engine. The process of dismantling cylinder head entails the following, that is the removal of Intake Valves, Exhaust Valves and other related parts. If they are still in place, dismantle all the rocker arm shafts and camshaft of SOHC engine, and the bearing caps, camshafts, rocker arms and lash adjusters of the DOHC engine. Some parts can be labeled and put back to where they will be needed while there are those that should be placed separately and then be replaced again in the intended area. Before depowdering the valves, make a tag and place together with the rest part of the respective valve so that they are not mixed up when reinstalled on the valve guides. Take off the keepers on the first valve and, with a spring compressor, compress the springs and take off the retainer and the spring. Pull the valve out of the head pulling its stem up thus removing the valve stem seal, further, pull the spring seat out of the guide. Sealing of valve stems and spring mounting are combined on four-cylinderic engines. If it freezes in the guide, it is removed back to the head and the surface around the keeper groove and the step tip should be cleaned with a fine file or whetstone. Perform the same for the other valves, assembly all components of the valve together to reassemble. Once the valves and components are out and placed properly the head of the valve has to be cleaned and examined. If you are having your engine rebuilt completely, go for total engine disassembly before going for cleaning and scrutinity of the cylinder head.