My Garage

My Account

Cart

Genuine Chrysler PT Cruiser Crankshaft Seal

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Crankshaft Seals found

Chrysler PT Cruiser Seal-Rear Main CRANKSHAFT

Part Number: 4621939AB$27.96 MSRP: $40.20You Save: $12.24 (31%)

Chrysler PT Cruiser Seal-Front Main CRANKSHAFT

Part Number: 4667198$16.73 MSRP: $23.75You Save: $7.02 (30%)

Chrysler PT Cruiser Seal-CRANKSHAFT Oil

Part Number: 5073675AB$34.39 MSRP: $79.25You Save: $44.86 (57%)

Chrysler PT Cruiser Crankshaft Seal

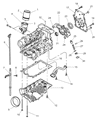

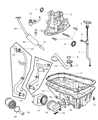

The Crankshaft Seal used in Chrysler PT Cruiser cars is an important one which is placed at the front of an engine. Assembled usually from metal and rubber, this round seal is very important to keep the crankcase from releasing the engine oil in order to lubricate some of the most important components of the engine. Crankshaft Seal is another Chrysler PT Cruiser part that could either be worn or damaged and results to oil leaks especially the high mileage models. Any Signs of failure of Crankshaft Seal should not be ignored since it needs to be replaced to get optimum performance of the car and prevent further damage of the engine. In general, the Crankshaft Seal can be regarded as one of the most important and, at the same time, the least complicated part of the Chrysler PT Cruiser engine that plays a crucial role in the car's steady performance.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler PT Cruiser Crankshaft Seal at great affordable prices. Moreover, all genuine Chrysler PT Cruiser Crankshaft Seal come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler PT Cruiser Crankshaft Seal Parts Questions & Experts Answers

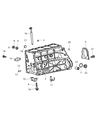

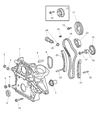

- Q: How to replace Crankshaft Seal on Chrysler PT Cruiser?A:Do not rotate the Camshaft(s) or crankshaft when the Timing Belt is removed or damage to the engine may occur. Begin by removing the timing belt. Measure the installed depth of the crankshaft sprocket in relation to the end of the crankshaft or the front of the engine, as this is important for proper timing belt alignment. Use a bolt-type gear puller to remove the crankshaft sprocket, and then take out the Woodruff key. Wrap the tip of a small screwdriver with tape and, working from below the right inner fender, pry the seal out of its bore, taking care to avoid damaging the Oil Pump assembly, crankshaft, and seal bore. Clean and inspect the seal bore and sealing surface on the crankshaft, removing minor imperfections with emery cloth; if a groove is worn in the sealing surface, a new seal may not stop the leak. Lubricate the new seal with engine oil and drive it into place using a hammer and an appropriately sized socket. The remaining steps involve reversing the removal process. The crankshaft sprocket depth is set to a factory specification to ensure correct timing belt alignment. If available, use the special factory tool with a built-in setting to install the crankshaft sprocket or carefully push it on until it is in the same position as previously measured. Position the crankshaft sprocket with the word FRONT facing out before installing it onto the crankshaft. Finally, reinstall the timing belt(s) and covers, then run the engine and check for oil leaks.