My Garage

My Account

Cart

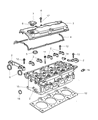

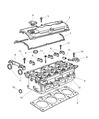

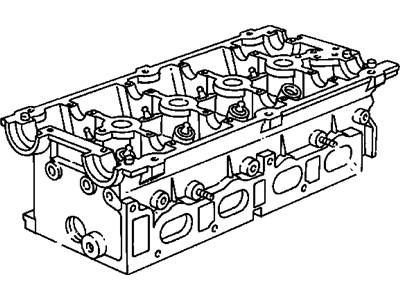

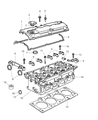

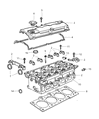

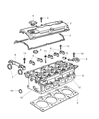

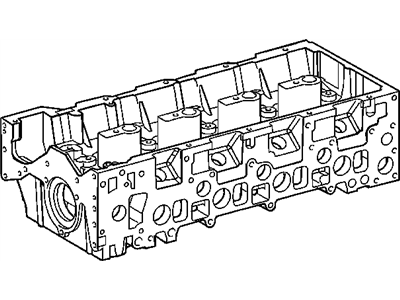

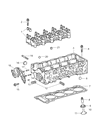

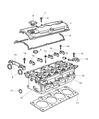

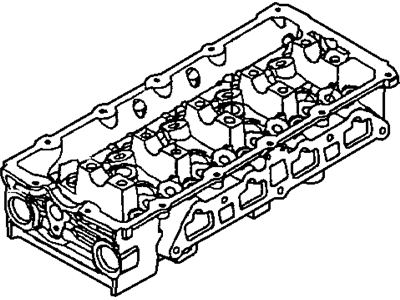

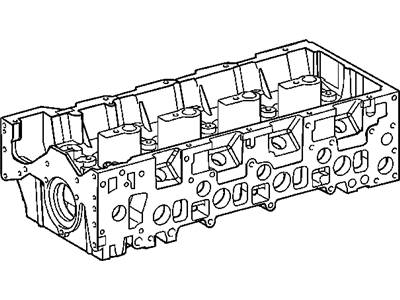

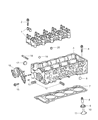

Genuine Chrysler PT Cruiser Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

14 Cylinder Heads found

Chrysler PT Cruiser Cylinder Head

Part Number: R8249421AA$1097.65 MSRP: $1340.00You Save: $242.35 (19%)Chrysler PT Cruiser Cylinder Head

Part Number: R5424847$1179.40 MSRP: $1395.00You Save: $215.60 (16%)

Chrysler PT Cruiser Cylinder Head

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Chrysler PT Cruiser Cylinder Head at great affordable prices. Moreover, all genuine Chrysler PT Cruiser Cylinder Head come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Chrysler PT Cruiser Cylinder Head Parts Questions & Experts Answers

- Q: How do you properly remove and reinstall a cylinder head on Chrysler PT Cruiser?A:Position the number one piston at Top Dead Center, disconnect the cable from the negative battery terminal, drain the cooling system, and remove the spark plugs. Remove the Intake Manifold, covering the intake ports with duct tape to keep out debris before removing the cylinder head. If necessary, remove the Exhaust Manifold, noting that on some models it may be easier to remove after the cylinder head. Remove the coil, Timing Belt, and valve cover. Loosen the cylinder head bolts, 1/4-turn at a time, in reverse of the tightening sequence until they can be removed by hand, and write down the location of the different length bolts for correct reinstallation. Carefully lift the cylinder head straight up and place it on wood blocks to prevent damage to the sealing surfaces, using a wood block and hammer or a prybar if it sticks to the engine block. Exercise caution as the cylinder head is aluminum and can be damaged easily. It is advisable to check the head for warpage even if only the gasket is being replaced. Use special gasket removal solvents to soften and remove old gasket material, ensuring nothing falls into the engine, and clean all threaded fasteners and holes. Place a new gasket and the cylinder head in position on the engine block, applying clean engine oil to the cylinder head bolt threads before installation. Tighten the cylinder head bolts in several stages according to the recommended sequence to the specified torque, using an angle-torque gauge if available, or marking the bolt heads to track the degrees tightened. Reinstall the timing belt and the remaining parts in reverse order of removal, refill and bleed the cooling system, and check all fluid levels. Rotate the crankshaft clockwise slowly by hand through six complete revolutions and recheck the Camshaft timing marks. Start the engine and run it until normal operating temperature is reached, checking for leaks and proper operation.