My Garage

My Account

Cart

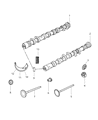

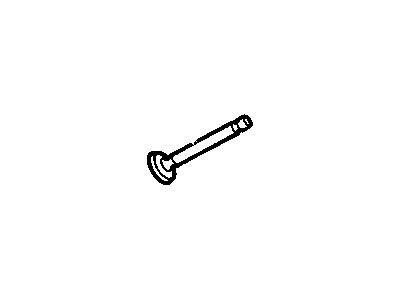

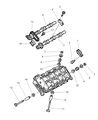

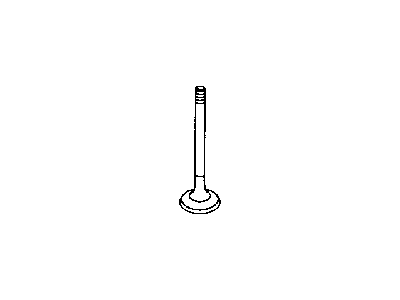

Genuine Dodge Avenger Exhaust Valve

Exhaust Muffler Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Exhaust Valves found

Dodge Avenger Valve, Exhaust - Standard

Part Number: 4667972$33.39 MSRP: $43.14You Save: $9.75 (23%)

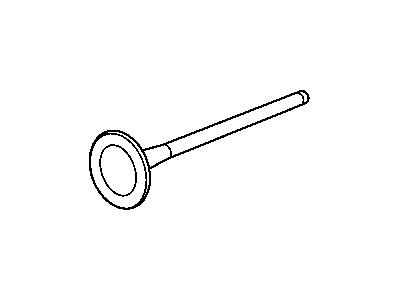

Dodge Avenger Exhaust Valve

The exhaust valve here in Dodge Avenger is indispensable in the internal combustion engine in that it helps expel the spent exhaust gases from the cylinders. This process helps in retaining the optimal engine condition since any problem with the Exhaust Valve will lead to problems like poor power output, rough acceleration, stumble while idling and low fuel consumption. Dodge Avenger models may come with different Type of Exhaust Valves and this has an influence on the efficiency and durability of the models. It is useful to know what type of Exhaust Valve is installed in a specific Dodge Avenger so as to identify problems and troubleshoot properly.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Avenger Exhaust Valve at great affordable prices. Moreover, all genuine Dodge Avenger Exhaust Valve come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Avenger Exhaust Valve Parts Questions & Experts Answers

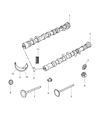

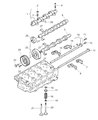

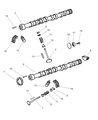

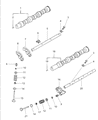

- Q: How to adjust valve clearance on Dodge Avenger?A:Note that 2015 and later models do not require valve adjustment. Position the number 1 piston at TDC on the compression stroke. Remove the engine cover by pulling it up and off the ball studs. Disconnect the negative battery cable from the remote ground terminal. Blow out the recessed area around the spark plug openings with compressed air, if available, to remove any debris that might fall into the cylinders, then remove the spark plugs. Remove the valve cover. The lobes must be measured one set at a time; rotate the Camshaft(s) until two lobes on any one cylinder are pointing straight up and measure the clearances of those valves with feeler gauges, ensuring a slight drag on the gauge indicates correct clearance. Rotate the camshaft(s) until all the lobes have been checked. Remove the camshaft(s) for the valve(s) that you intend to adjust. Remove and measure each lifter with a micrometer, recording the measurement for each lifter before moving on to the next. To calculate the correct thickness of a replacement lifter that will put the valve clearance within the specified range, use the formula S - C equals change, where S is the specified valve clearance and C is the measured valve clearance. Remove the lifter and read the size from the bottom, then reduce the lifter by subtracting the specified valve clearance from the measured valve clearance or as close as possible to the calculated size. Install the camshaft(s) and check the valve clearances again to verify they are now within the range. The remainder of installation is the reverse of removal.