My Garage

My Account

Cart

Genuine Dodge Challenger Pressure Plate

Clutch Pressure Plate- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Pressure Plates found

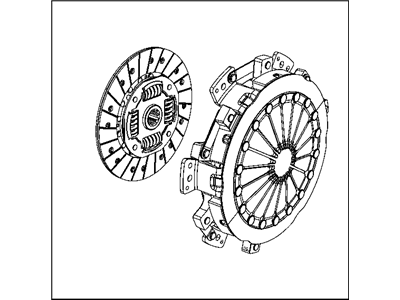

Dodge Challenger Plate-Pressure Plate And Disc

Part Number: 5038119AH$916.35 MSRP: $1375.00You Save: $458.65 (34%)

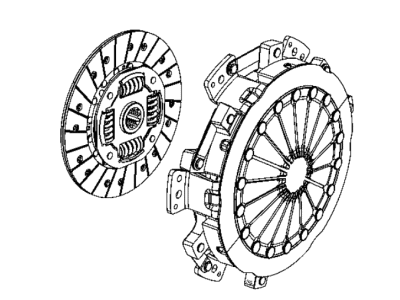

Dodge Challenger Clutch-Pressure Plate And Disc

Part Number: 5038769AB$1952.50 MSRP: $2985.00You Save: $1032.50 (35%)

Dodge Challenger Pressure Plate

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Challenger Pressure Plate at great affordable prices. Moreover, all genuine Dodge Challenger Pressure Plate come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Challenger Pressure Plate Parts Questions & Experts Answers

- Q: How do you remove and install Pressure Plate on Dodge Challenger?A:The parts of the clutch are usually accessed by pulling off the transmission but with the engine still in the car. In case the engine is being pulled and the major overhaul is the plan, one has to inspect the clutch for wear and replace all worn parts in the clutch assembly. First, do away with the transmission itself. To assist in holding the clutch disc in place during the removal process you are required to insert a clutch alignment tool through the clutch disc hub. The flywheel and the pressure plate should be checked for the presence of indexing marks which may be in form of an X or an O, or a white letter. If these marks are not visible, draw new marks in order to install the sheet properly in regards to the vertical position. Relax the pressure plate to flywheel bolt and ease it to the 1/4 turn at an interval of every other bolt until the spring tension is canceled; then unbolt the pressure plate, and finally remove the clutch disc. Inspection: look for cracks, heat checking, grooves or other defects on the flywheel surface, if the defects are not deep a machine shop should be able to turn the surface of the flywheel. Check for smooth surfaces on the Pilot Bearing an replace as and when needed. There should be 1/16-inch clearance from the linings to the clutch disc; examine for loose or distorted rivets, cracking, broken springs, and the like. If in doubt that the clutch disc is worn replace it and if one disc is worn the other disc and pressure plate should also be replaced. As a rule, the release bearing is replaced together with the clutch disc. Inspect the machined surfaces and diaphragm spring fingers of the pressure plate for any damage; if the surface is grooved, possibly, it should be taken to a machine shop for machining or have a replacement. Also before the installation ensure that the Machined surfaces of the flywheel and the pressure plate do not have any form of oil grease on them. Align the clutch disc and pressure plate as should be when the clutch is in use by making use of an alignment tool. Loosen the pressure plate-to-flywheel bolts by turning them only as much as is necessary to apply fingers from the next step, then align the clutch disc by means of inserting the alignment tool in to the splined hub, and to the pilot bearing on the end of the crankshaft. As the fastening torque is approached, the bolts should be alternated back and forth in a cross-wise pattern to keep the clamping faces parallel to avoid any distortion during tightening until all bolts are in place, in which Torque to the specified fastening torque while holding the alignment tool and then remove it. Finally, install the transmission.