My Garage

My Account

Cart

Genuine Dodge Challenger Sway Bar Kit

Stabilizer Sway Bar Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

20 Sway Bar Kits found

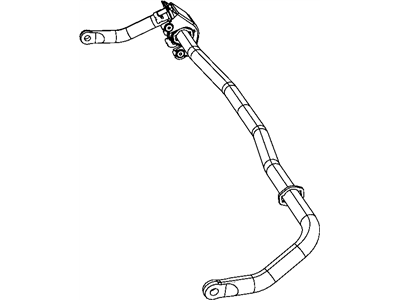

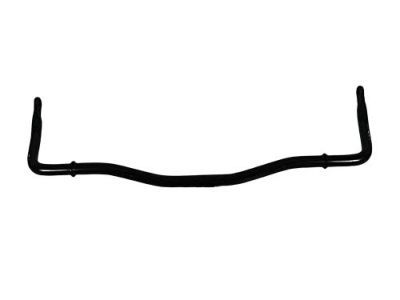

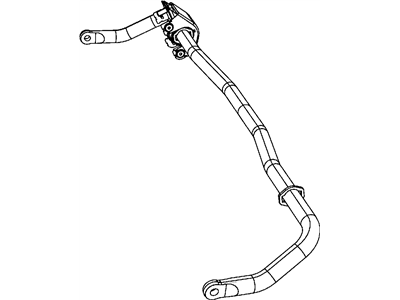

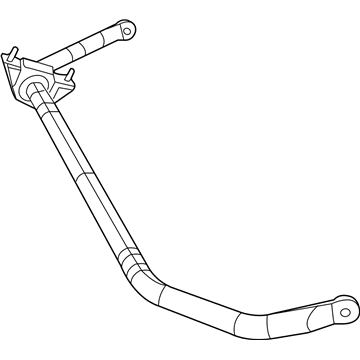

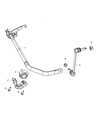

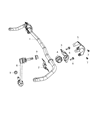

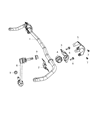

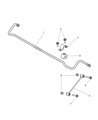

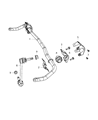

Dodge Challenger Rear Suspension Bar

Part Number: 68184225AA$95.25 MSRP: $211.00You Save: $115.75 (55%)

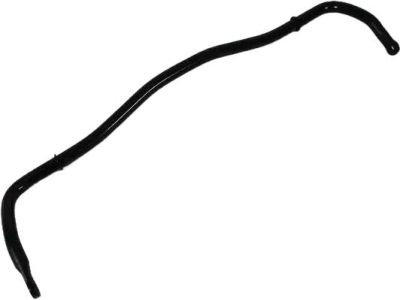

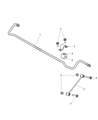

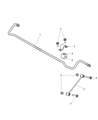

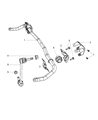

Dodge Challenger Rear Suspension Bar

Part Number: 4782873AB$103.82 MSRP: $154.00You Save: $50.18 (33%)

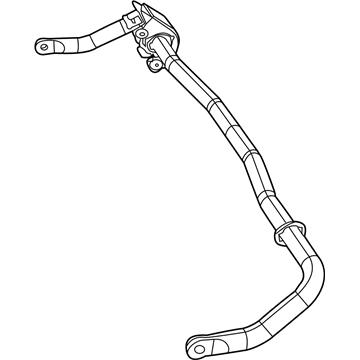

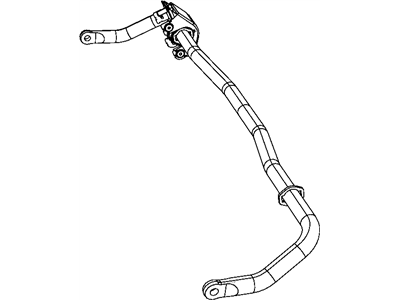

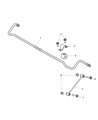

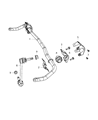

Dodge Challenger Rear Suspension Bar

Part Number: 68235662AA$246.42 MSRP: $372.00You Save: $125.58 (34%)

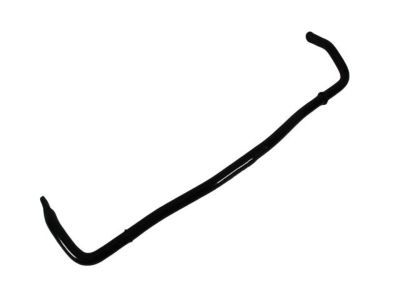

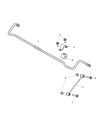

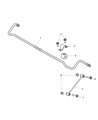

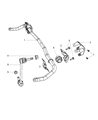

Dodge Challenger Rear Suspension Bar

Part Number: 5180016AA$113.87 MSRP: $169.00You Save: $55.13 (33%)Dodge Challenger Rear Suspension Bar

Part Number: 4782874AB$101.69 MSRP: $118.00You Save: $16.31 (14%)

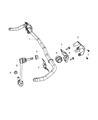

Dodge Challenger Rear Suspension Bar

Part Number: 68184227AA$146.64 MSRP: $219.00You Save: $72.36 (34%)

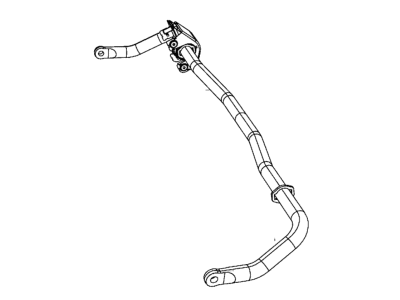

Dodge Challenger Rear Suspension Bar

Part Number: 68184226AA$133.10 MSRP: $199.00You Save: $65.90 (34%)

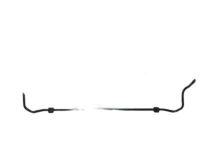

Dodge Challenger Sway Bar Kit

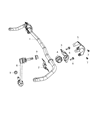

The Sway Bar Kit in Dodge Challenger vehicles is primarily intended to improve on the handling of the car since it reduces on body roll that may be experienced when cornering or when the car is on an irregular surface. This is an anti roll bar that links opposite wheels by the torsion spring thus increasing the roll stiffness without affecting the spring vertical stiffness. The Sway Bar Kit helps to counteract the torsion which in turn helps the four wheels rise to a similar level thereby lessening the lateral tilt and therefore enhancing the firmness of the car when it is on the road. There are normally different models of Sway Bar Kits that have been used in Dodge Challenger cars where they include the adjustable as well as the active Sway Bar Kits. These advanced Sway Bar Kits can offer either fixed stiffness, or change stiffness according to its features of handling characteristics and stability. Though Sway Bar Kits of the older models may convey shocks between wheels thus resulting in a 'waddling' experience over high ground, Sway Bar Kits in modern cars have gradually been integrated for the improvement of ride quality and performance as is evidenced by the Sway Bar Kits in the Dodge Challenger family.

Looking for affordable and high-quality auto parts? Then you have already arrived at the proper online shop. We offer all Dodge Challenger Sway Bar Kit at great affordable prices. Moreover, all genuine Dodge Challenger Sway Bar Kit come with a manufacturer's warranty. In the long run, you would realize you have saved a lot of trouble and money with OEM parts from here.

Dodge Challenger Sway Bar Kit Parts Questions & Experts Answers

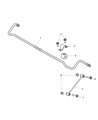

- Q: How to remove and reinstall rear stabilizer bar,bushing and link on Dodge Challenger?A:The following involves the use of a transmission jack or any other equivalent and it is advised that there should be an assistant during this procedure. First, get the cable out of the negative terminal of the battery. First, you need to turn the wheel lug nuts and raise the rear part of your vehicle with the help of jack, put jackstands under the frame rails and only then you can take off the wheel. Then, it is necessary to take out the rear part of the exhaust and to separate the drive shaft from the rear differential. Disconnect the subframe side parking brake equalizer from parking brake's front cable which is above the rear differential and then undo the bracket fastening parking brake cable to the subframe. Against the chassis, mark the subframe on all the four points of mounting. Place a floor jack under the spring link and insert a wood block under the floor jack to avoid the spring from compressing back, then, remove the nuts for the lower mounting of the Shock Absorber and slowly lower the floor jack until the spring is fully stretched. Lose the brake calipers and put them out of the way not to touch the brake hoses when lowering the subframe, and take off and unplug the ABS wheel speed harnesses from the chassis. While securing the rear sway bar to the transmission jack do not secure the differential along with it. Slide a transmission jack under the differential and tighten it and finally unbolt the fuel filler neck. With the transmission jack in position loose all the four subframe bolts then slowly lower the subframe in a way that the drive shaft would be detached from the differential until there is adequate space to work on the sway bar brackets. Use more jackstands or their equivalent to support the subframe and suspension assembly and then unbolt the retainers for the sway bar bracket; remove the bar and the brackets and note the position of the slits on the bar when removing the bushings. Wipe out the area where the bushings rest on the sway bar and check the bushings for signs of wear and or damages such as cracks, tears or deterioration and if you find any of these replace them. Lift the car and take off the sway bar links; visually check the ones you removed for signs of wear or damage; if there are any, replace them with new ones. Most of these procedures are carried out with equal measures as those that were followed during removal, the only major consideration being that before raising the subframe into final position, the lower shock absorber fasteners are to be placed in appropriate positions but not yet tightened up. During raising of subframe, check that coil spring and insulators are correctly positioned in the upper position and align the subframe with the previous markings. As the subframe is being positioned the driveshaft has to be connected to the rear differential and the top of the shock absorbers have to go under the chassis, this is done at the final moments when the subframe is being lowered into position. The bolts for fixing the subframe are of two different sizes; the longer bolts are fixed at the rear side and the shorter bolts fixed at the front side. Replace brake; fuel tank; driveline; exhaust parts; lift the spring link with a floor jack to set it close to normal ride height then final tighten lower shock absorber and sway bar link mounting bolts. Tighten all suspension fasteners to the specified torque and have the alignment of the wheels checked and corrected if needed.